Discarded Cemented Carbide Inserts High-precision Wear Corrosion

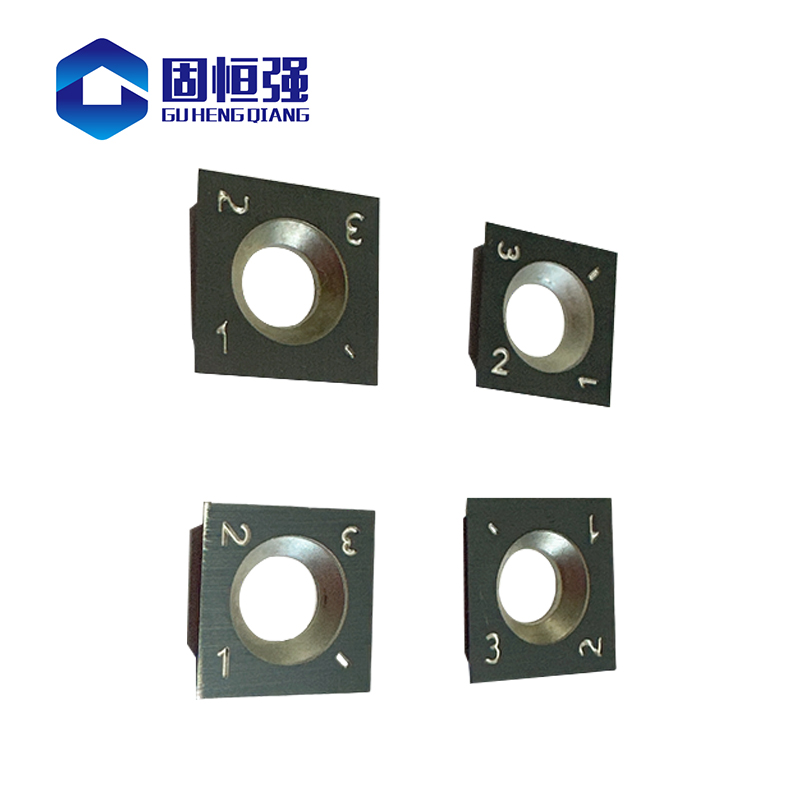

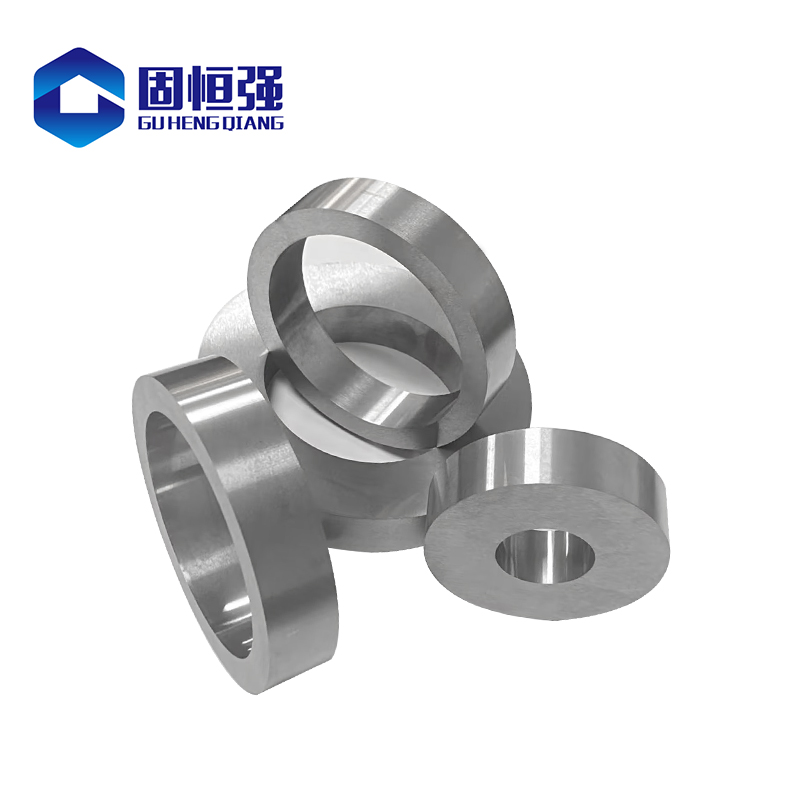

Discarded Cemented Carbide Inserts

Introduction of Discarded Cemented Carbide Inserts

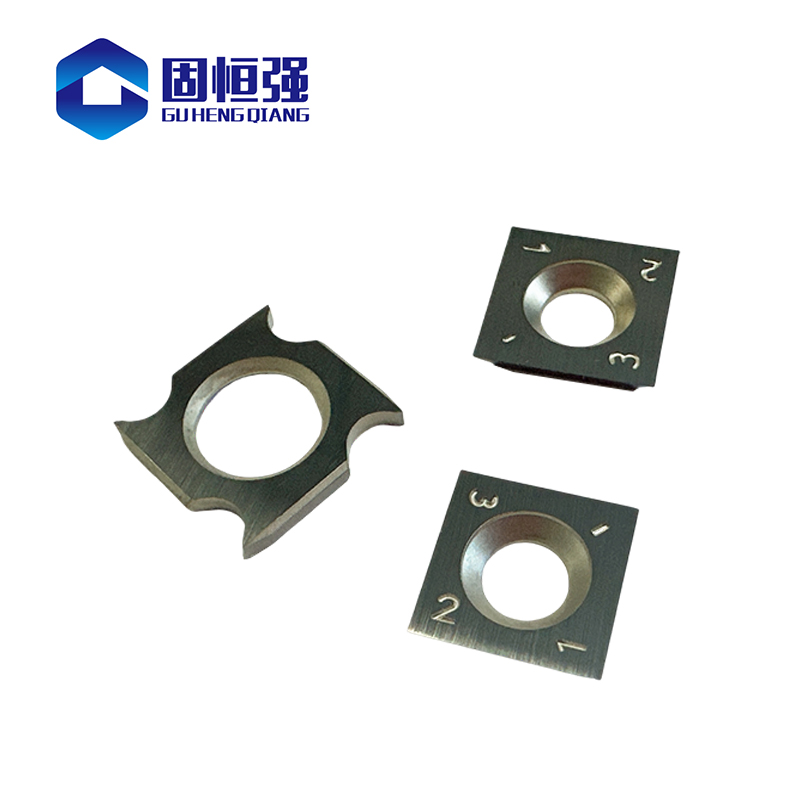

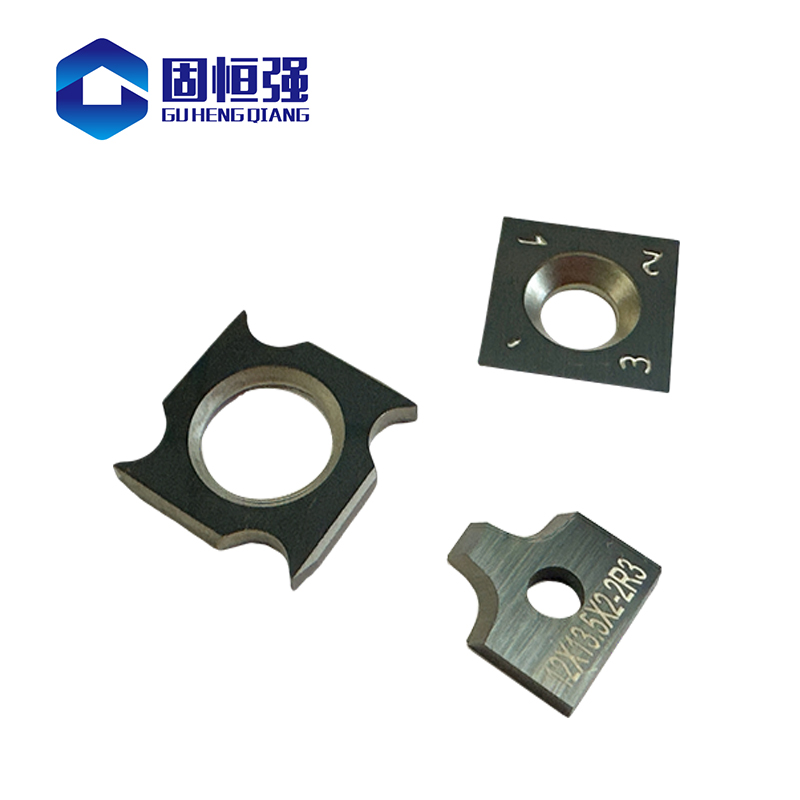

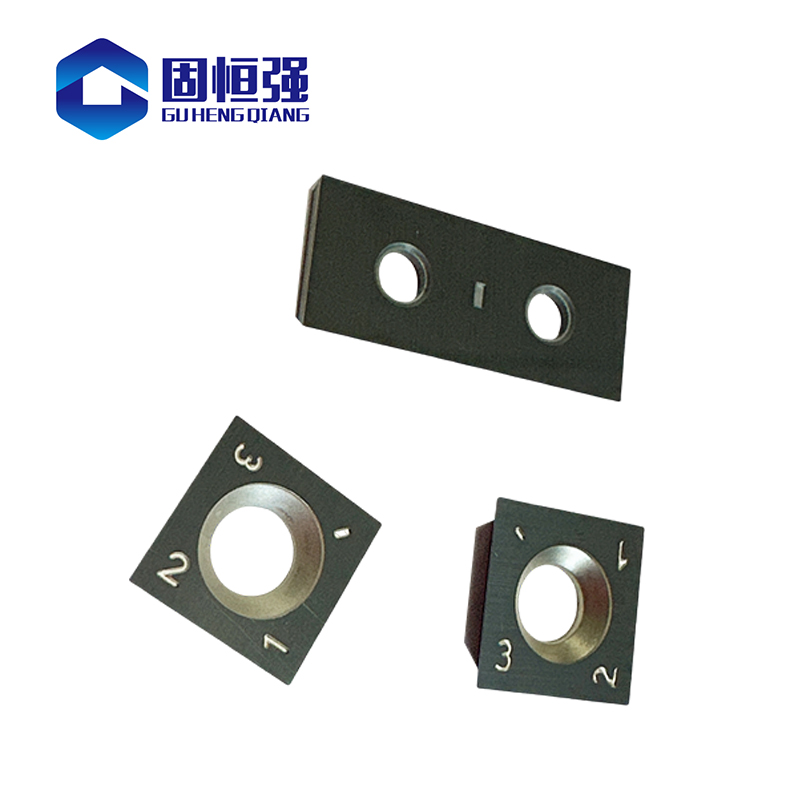

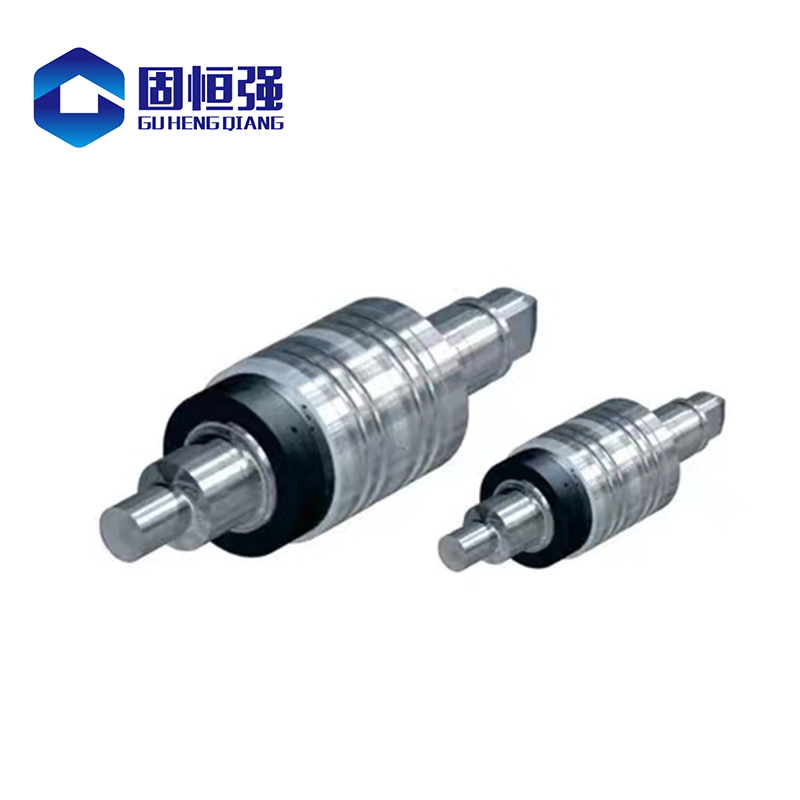

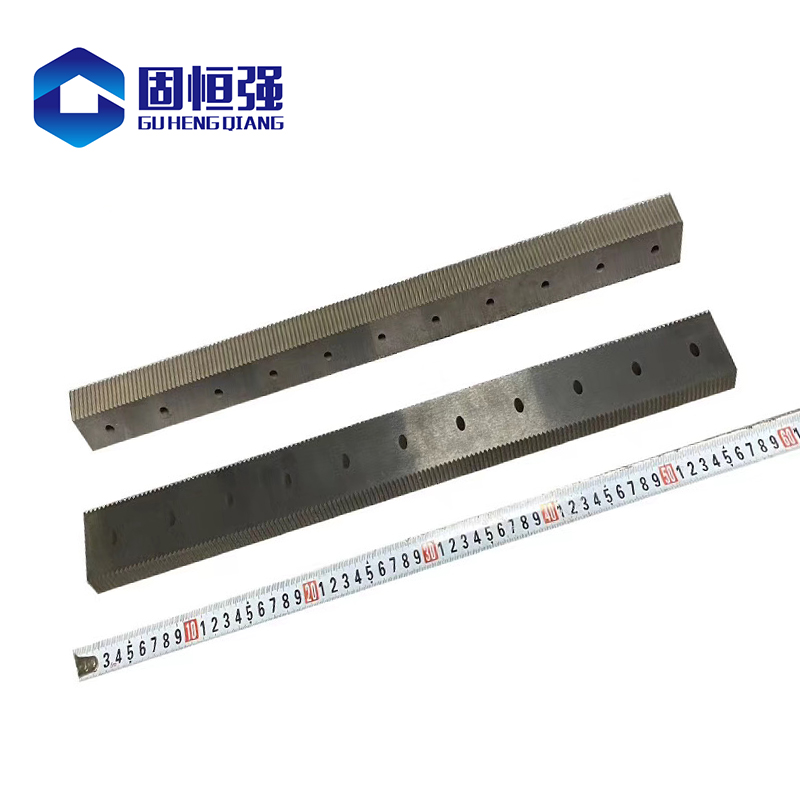

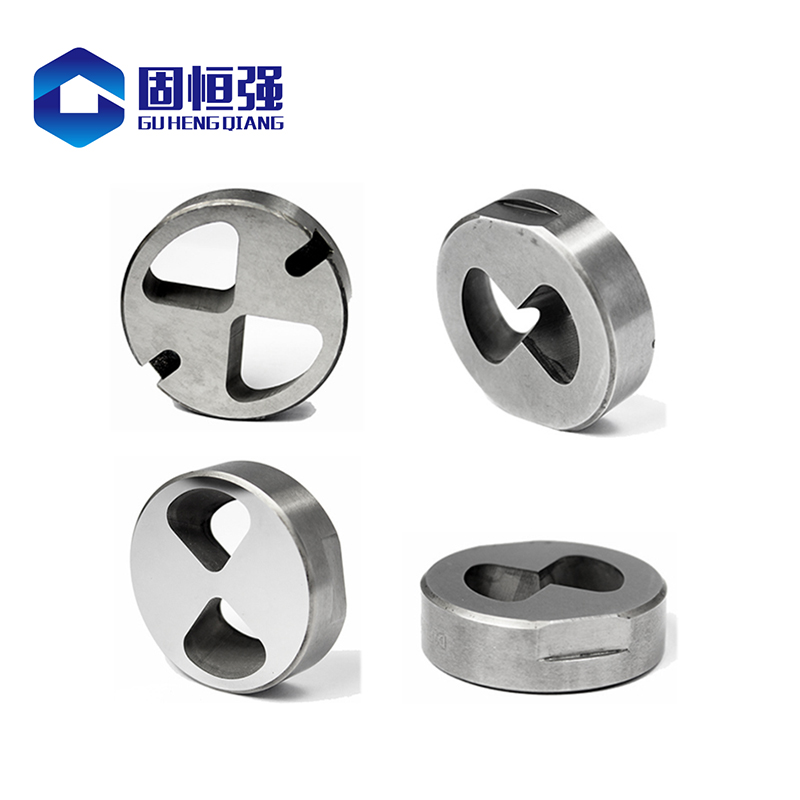

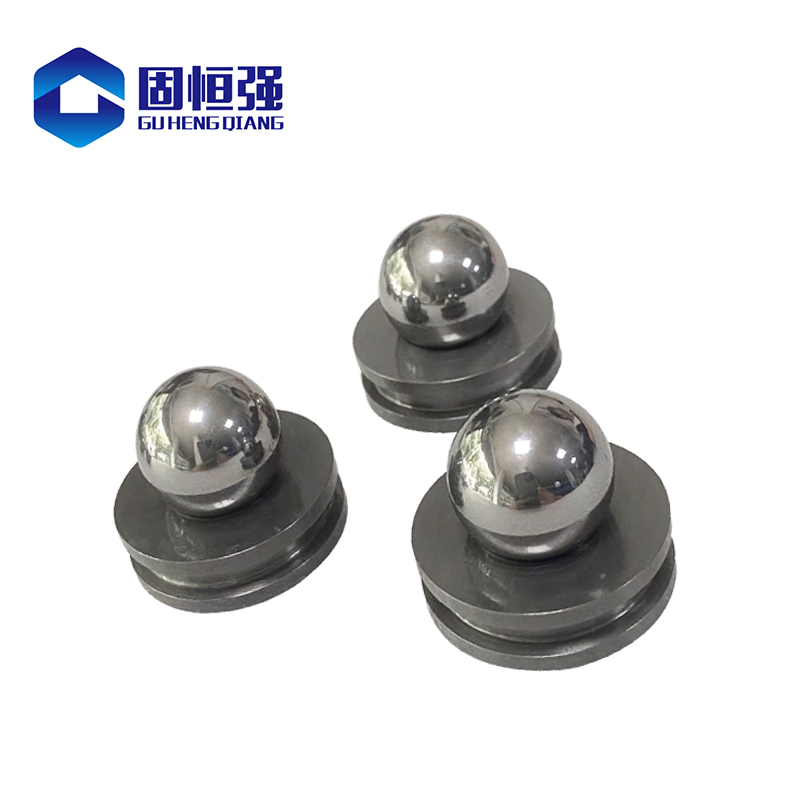

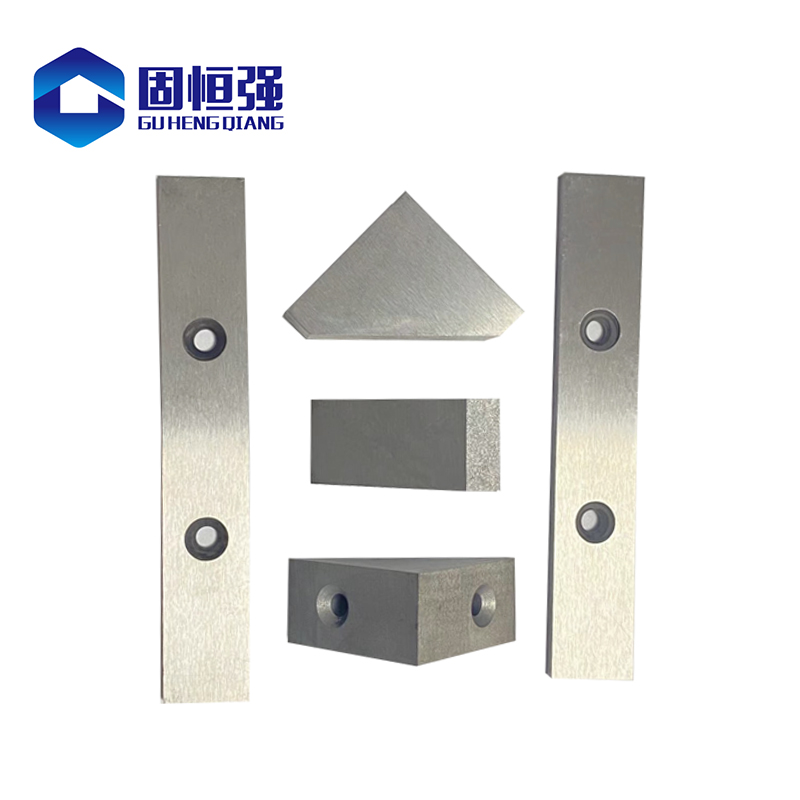

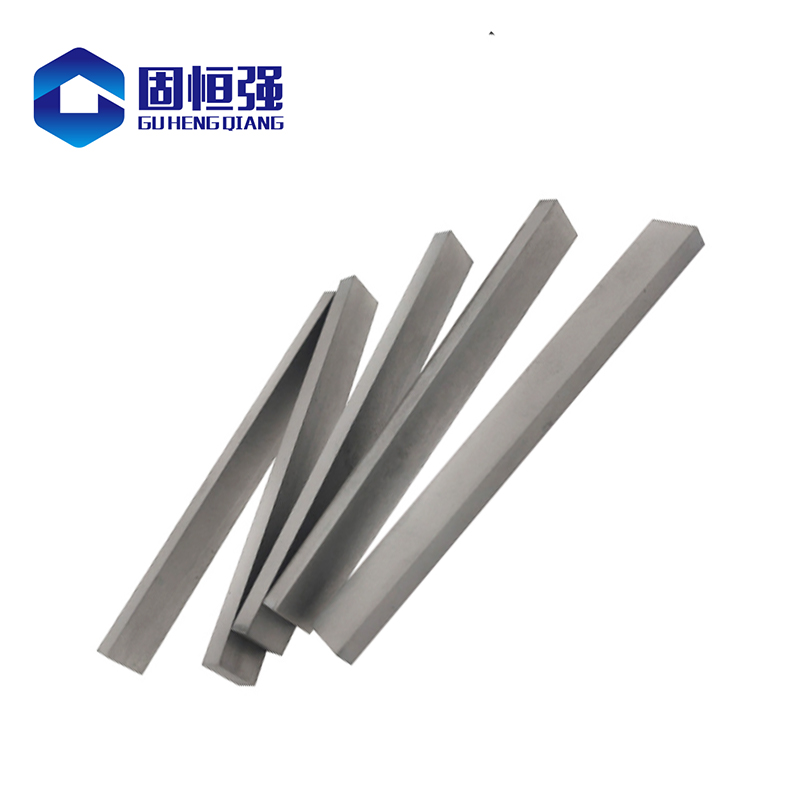

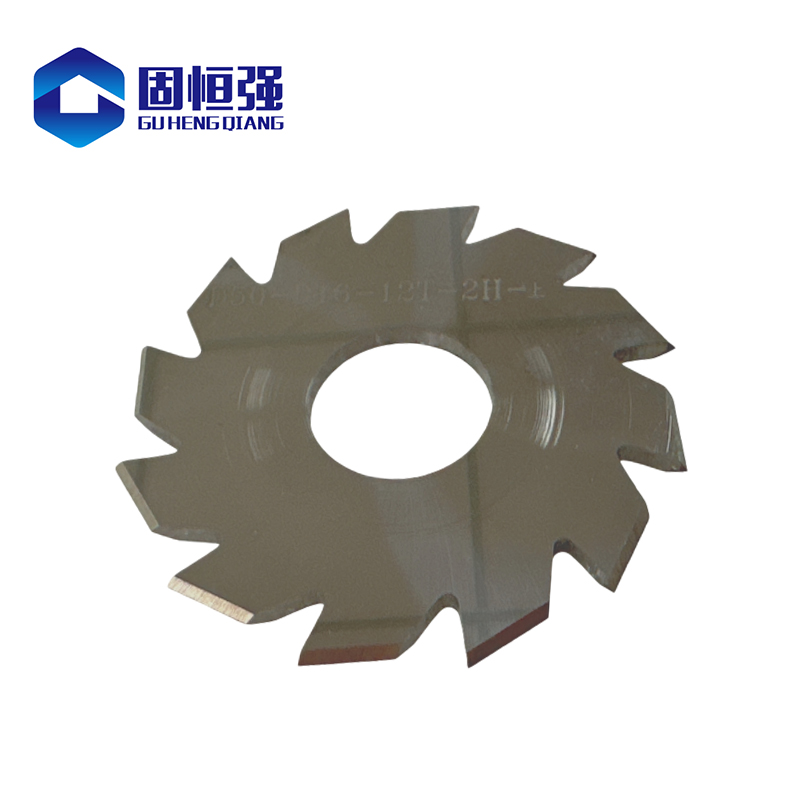

The discarded tungsten carbide inserts, also known as woodworking inserts, tungsten carbide inserts, pressure planer blade, double-sided planer blade, sanding machine blades. Its supporting spiral cutter head, cutter shaft, used for woodworking double-sided planer, four-sided planer vertical shaft machine, profiling machine and other machinery machine tools to split a variety of soft and hard solid wood particle board density board acrylic board and other boards.

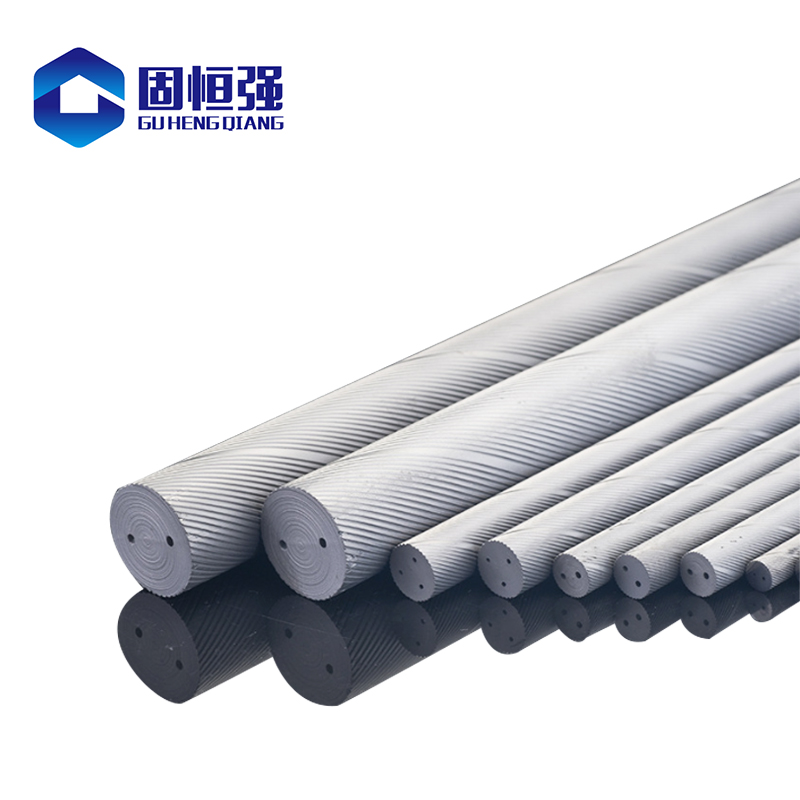

Processing technology: the blades are made of micron-grade granular raw materials, low-pressure sintering, wear-resistant and tough, not easy to break, and the durability and sharpness are more than 5 times that of ordinary knives.

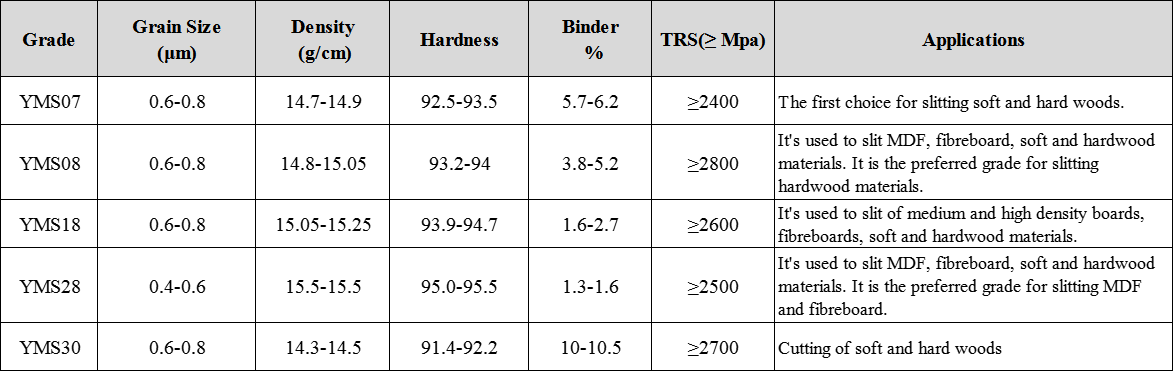

Discarded Cemented Carbide Inserts Grades

Characteristics of Discarded Cemented Carbide Inserts

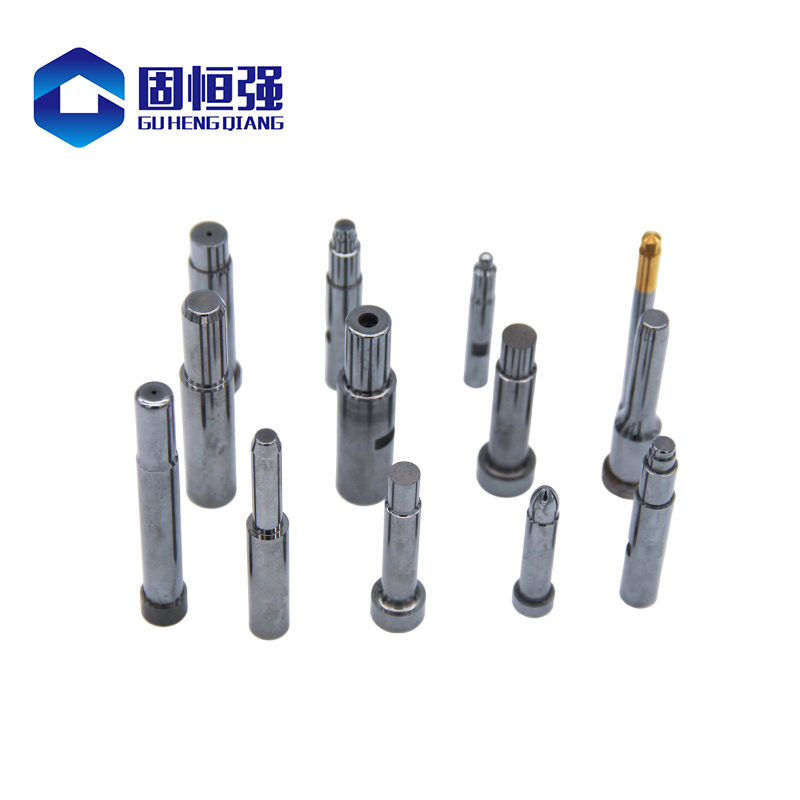

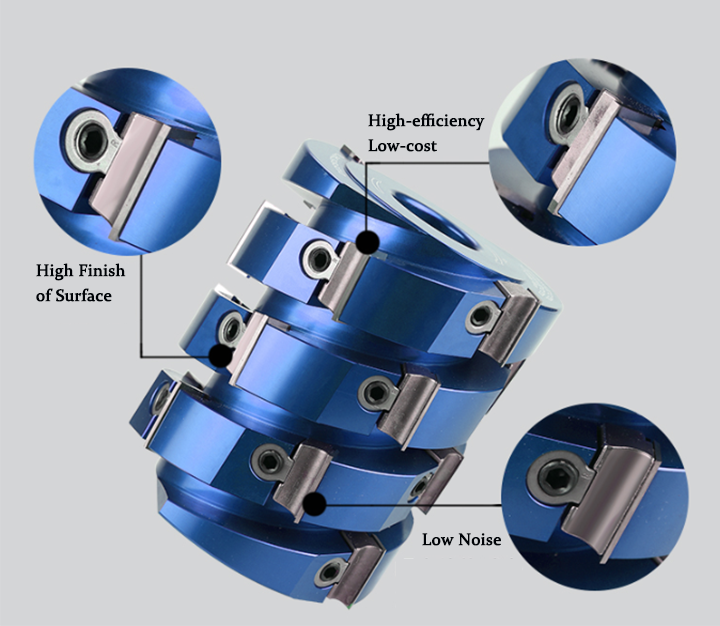

1.Improve production efficiency. Blade length is short, cutting resistance dispersed, blades available on all sides to replace the blades after use, reduce production time, improve productivity, reduce machine loss, reduce safety hazards.

2.High stability of cutting materials. Because of the repeated positioning characteristics of the spiral blade, not because of tool sharpening or replacement of the blade after the shape of the deviation caused by the thickness of the workpiece is not the same.

3.Low noise. With the spiral cutter head knife shaft can reduce the noise generated in the processing, contact with the surface of the wood processing noise generated by the value of about 30 to 50DB, point cutting characteristics can effectively prevent the wood processing process of the tearing situation. After cutting, the wood is as bright as a mirror. (Effective for mahogany hardwoods)

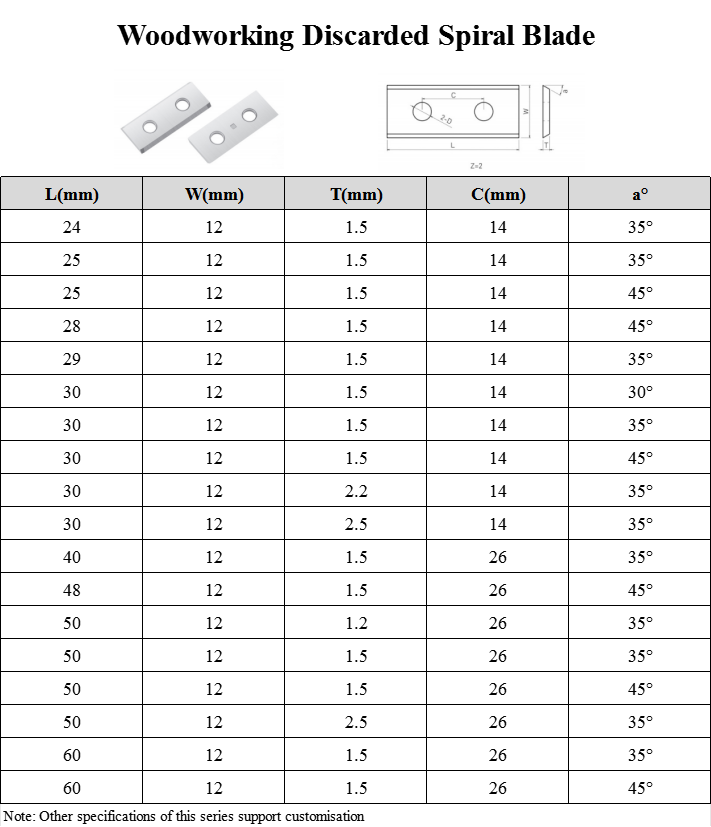

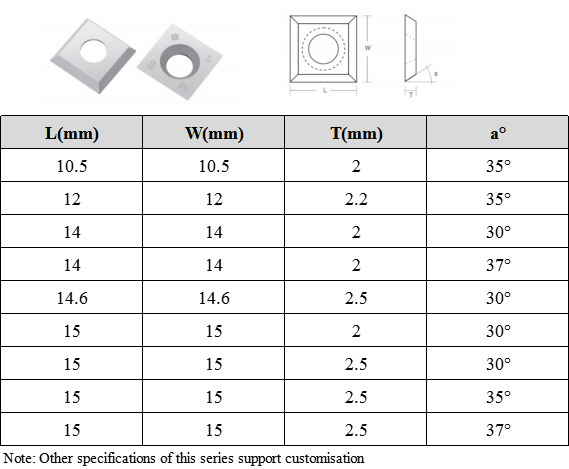

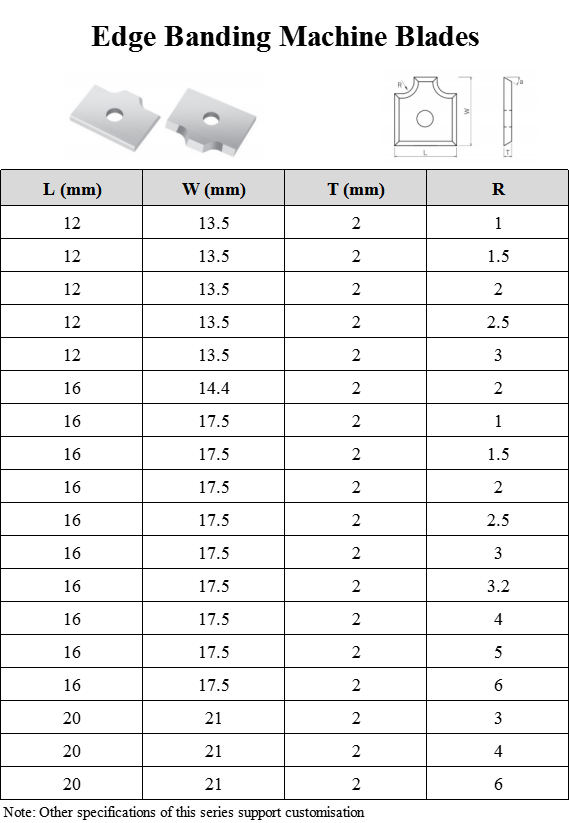

Specifications and Models of Discarded Cemented Carbide Inserts

Customized Instructions for Discarded Cemented Carbide Inserts

1.Customized according to your samples or drawings;

2.According to your working conditions to provide you with grades and provide design solutions, with professional solutions to the actual needs of customers!

Our company produces cemented carbide products, a variety of specifications, welcome to order! For you to comprehensively solve the production problems!

Precautions of Discarded Cemented Carbide Inserts

1.Read the instructions in detail before operating the tool to understand the correct operation method;

2.In the operation of the tool must be installed before a good safe and reliable device and check whether other safety guards are correct;

3.When operating the machine need to wear overalls is strictly prohibited to wear loose clothing or tie bracelet long hair need to bring a work cap to cover the hair;

4.poor mental state and lack of sleep after taking medication and drinking alcohol is strictly prohibited after the use of knives;

5.Before use, first check whether the components of each department loose and damaged, and timely adjustment or replacement to ensure normal use, and clean up the work area debris and tools;

6.It is strictly prohibited to install the tool without confirming clearly whether the spindle steering is correct or not, and the installation or replacement of the tool must be carried out after cutting off the main power supply;

7.Before processing wood, should first check the wood whether there are iron nails, sand and gravel and other hard objects;

8.All safety guards can not be opened or disassembled when the main power supply is not cut off and the machine is in operation;

9.The tool must be disconnected from the power supply after use, and wait for the machine spindle to stop completely before leaving.

-

Previous:

Non-magnetic Tungsten Steel Concave Mold Plunger

Next: No Data