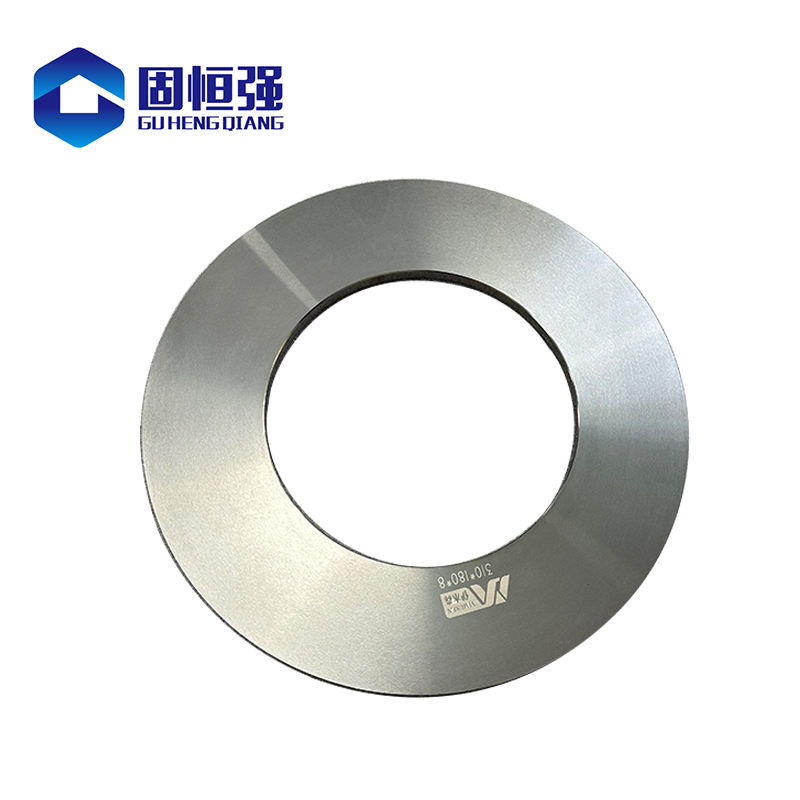

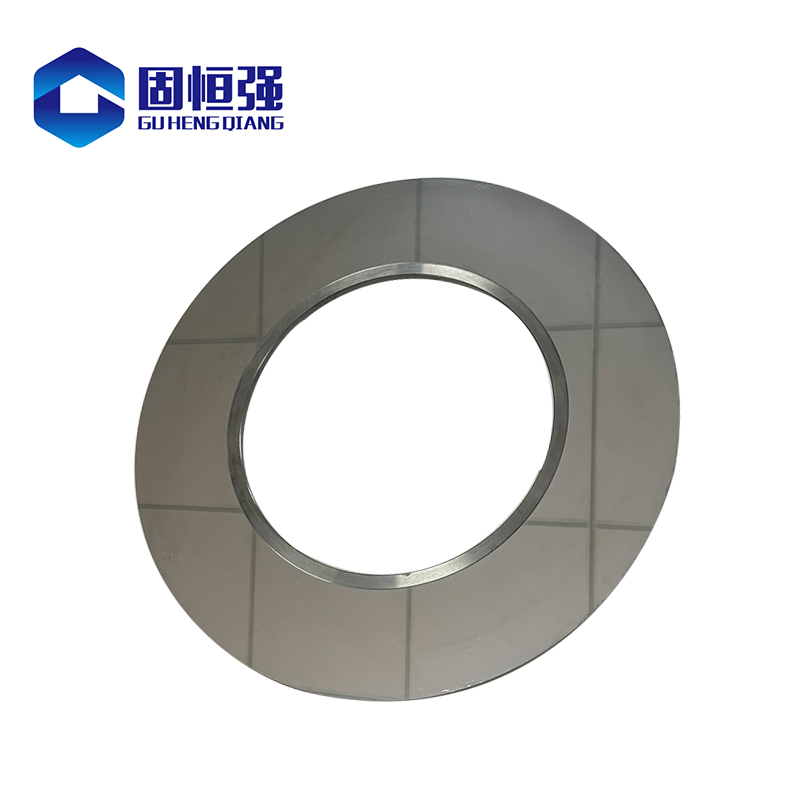

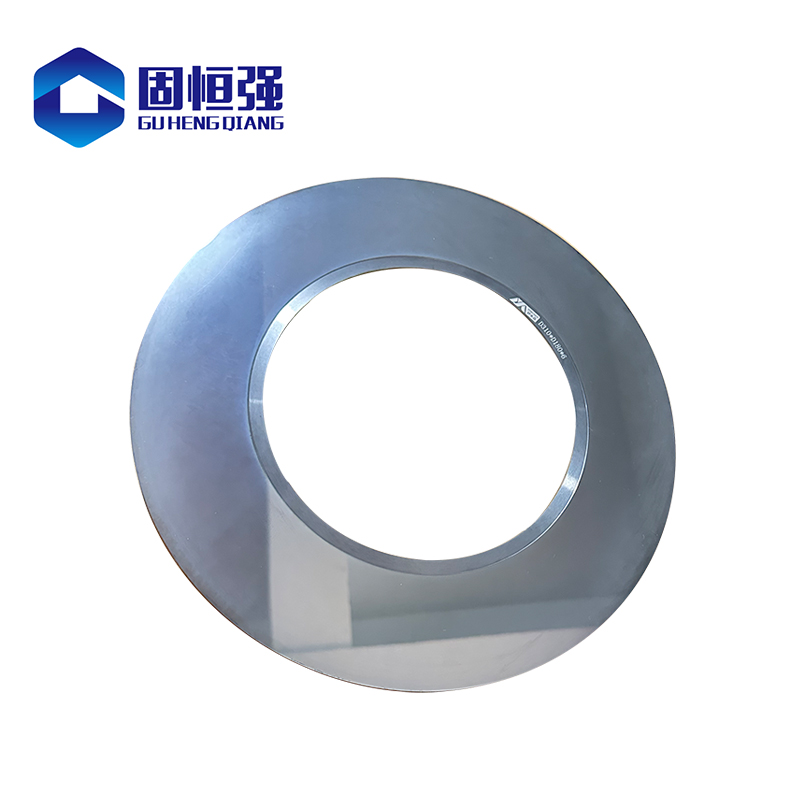

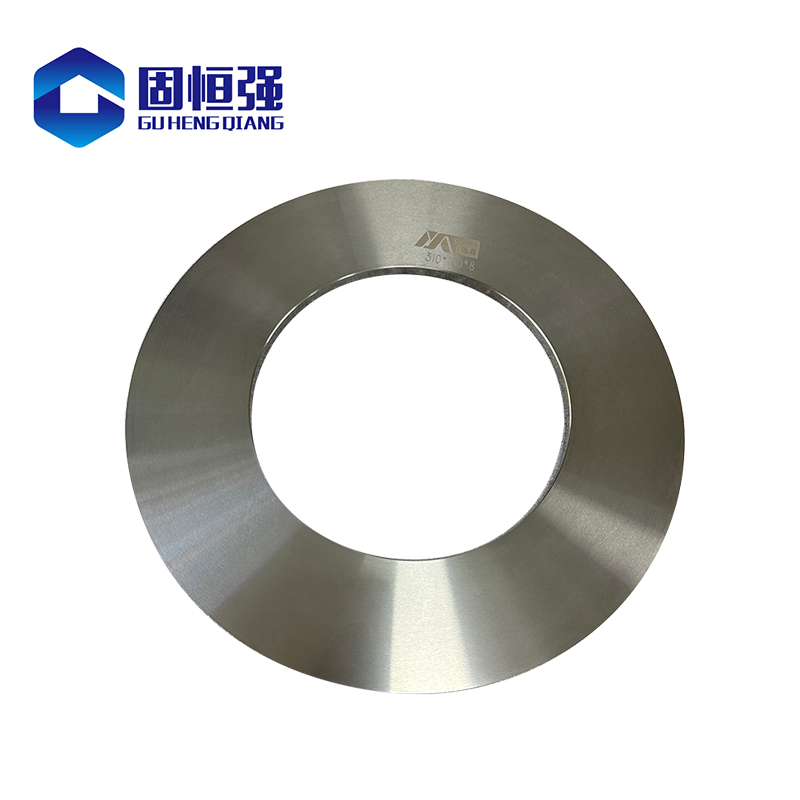

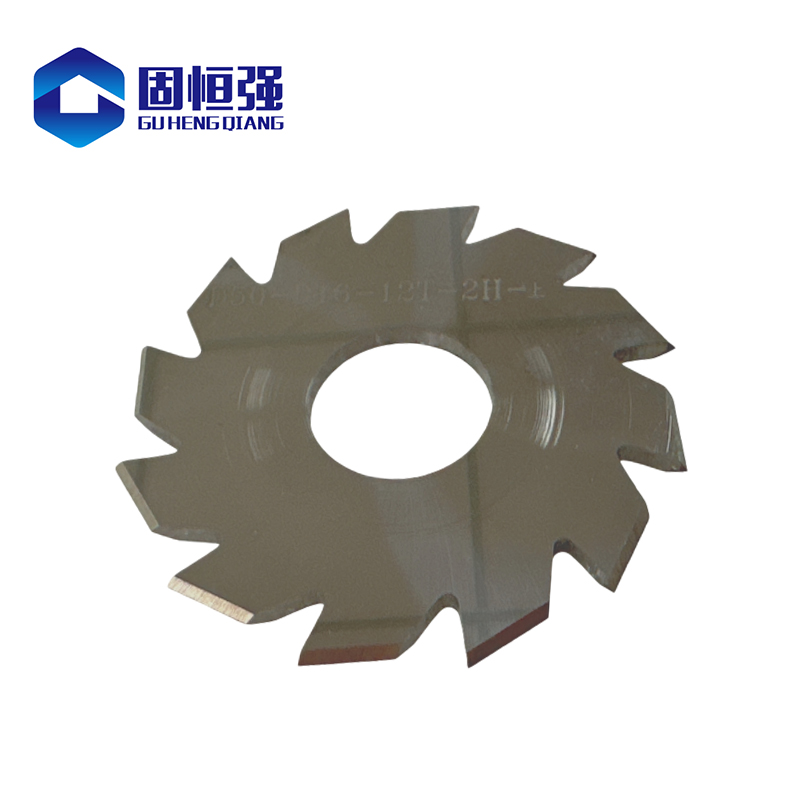

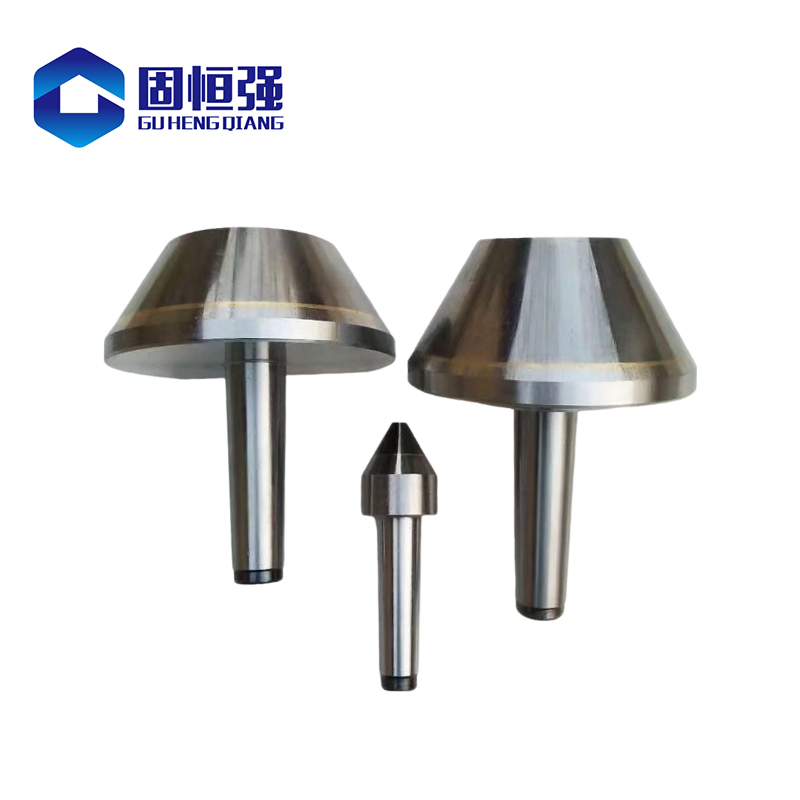

Tungsten Carbide Slitting Machine Knife/ Extreme Hardness And Wear Resistance

Products Description

1.Introduction of Oriented Steel Product

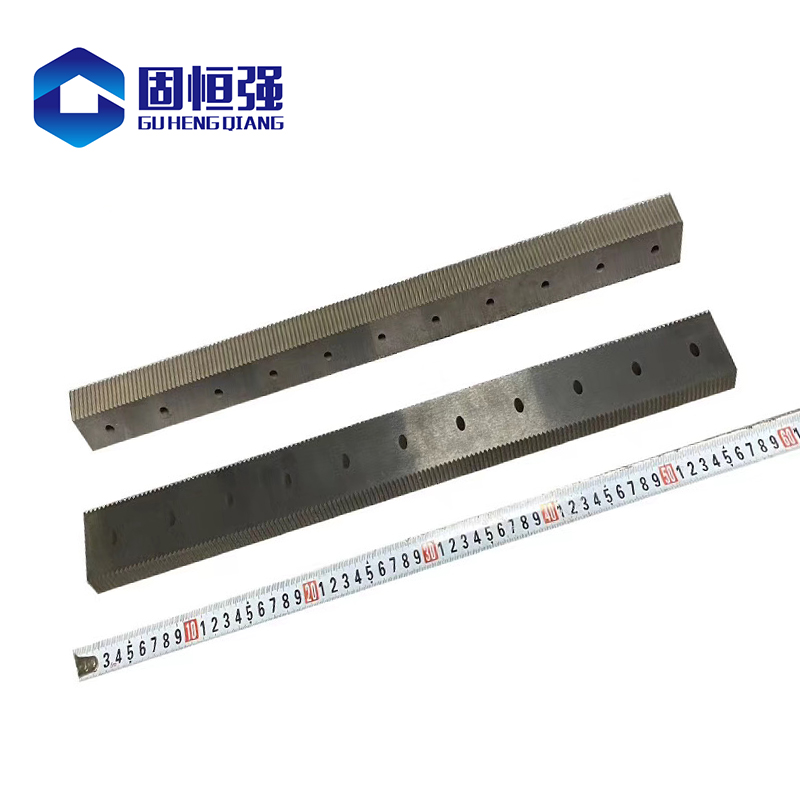

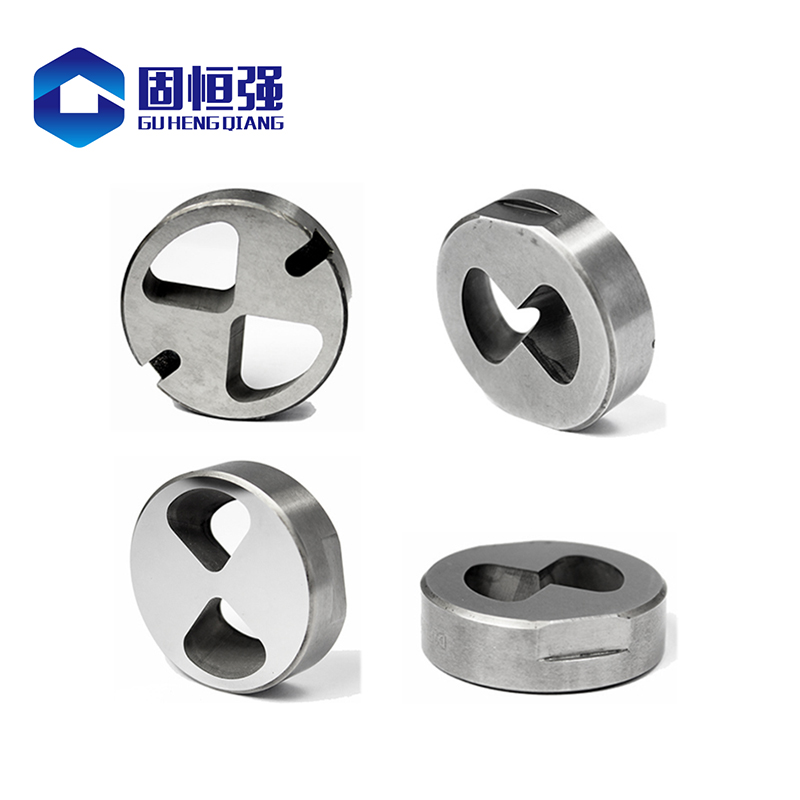

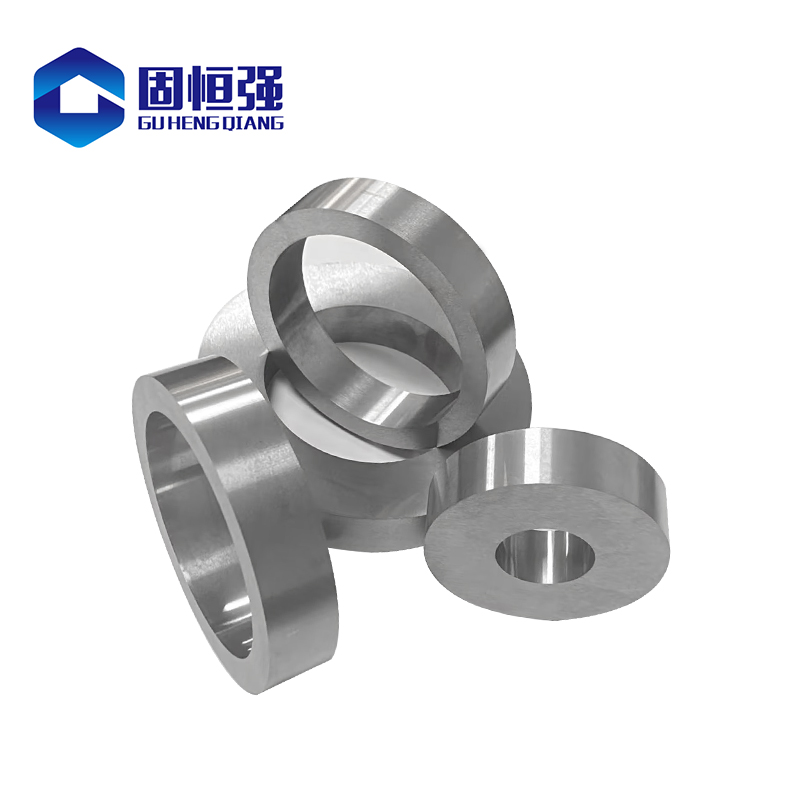

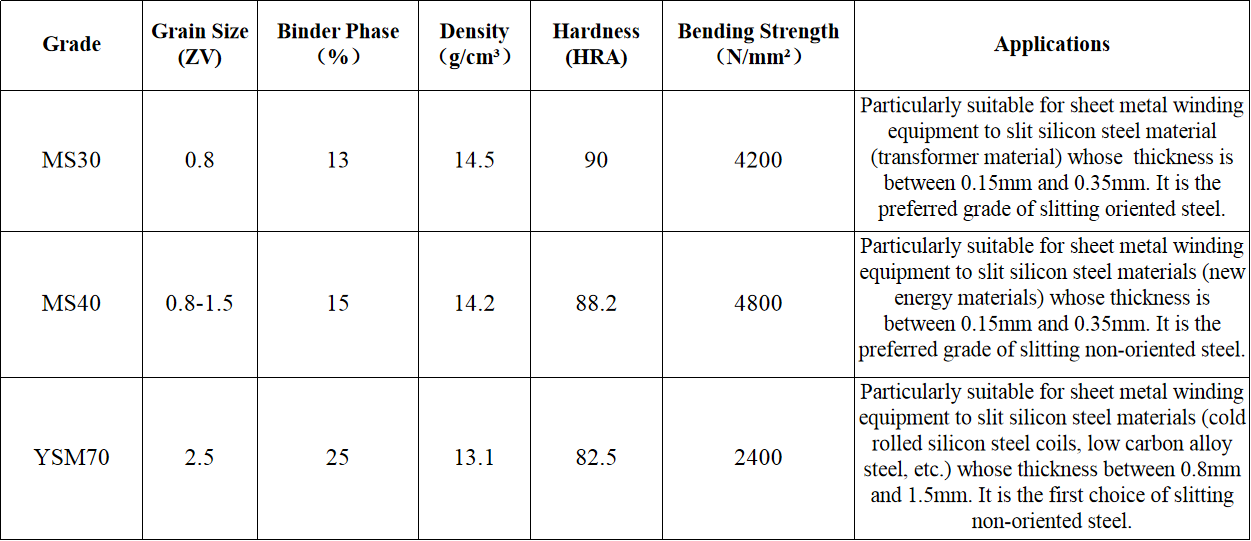

In terms of horizontal shear and longitudinal shear tungsten steel cutter blade, sales of our company in the home market are about 18 to 20 tons per year, accounting for almost 90% of the market share in this area. Main grades consist of the low-end grades like YG15 and YG20 , mid-range grades like MZ40, but the high-end grades market of shear oriented electrical steel is almost occupied by Japan and Germany. However, through many years of efforts, our company now researches and develops a grade MS30, which is a completely alternative to German and Japanese grades.

In the micro-structure of uniformity, etc. the new grade is equivalent, even slightly beyond the Japanese similar grades. In terms of stability and performance, it has reached the international level. When the blade slits the silicon steel materials whose thickness is between 0.15mm and 0.35mm, one side can slit 20 tons of materials, and double-sided can slit 40 tons with cutter repairing and grinding once and finishing products with burrs at 0.015mm.

2.Introduction of Non-oriented Steel Product

In the Chinese market, many factories are mainly used high-speed steel blade (grade SKH51 from Taiwan and KNH31 from Japan) to replace the non-oriented steel blade because of limited cost budget. Our company is currently researching and developing a grade MS40 carbide slitting blade, whose mechanical properties is 15-20 times of high-speed steel. When the blade slits the silicon steel material whose thickness is 0.2mm, 0.25mm, 0.3mm, and 0.35mm, in particular slitting New energy materials, one side can slit 530 tons, 15,000 meters of materials, and double-sided can slit 1,6000 tons, 30,000 meters with cutter repairing and grinding once and finishing products with burrs at 0.015mm.

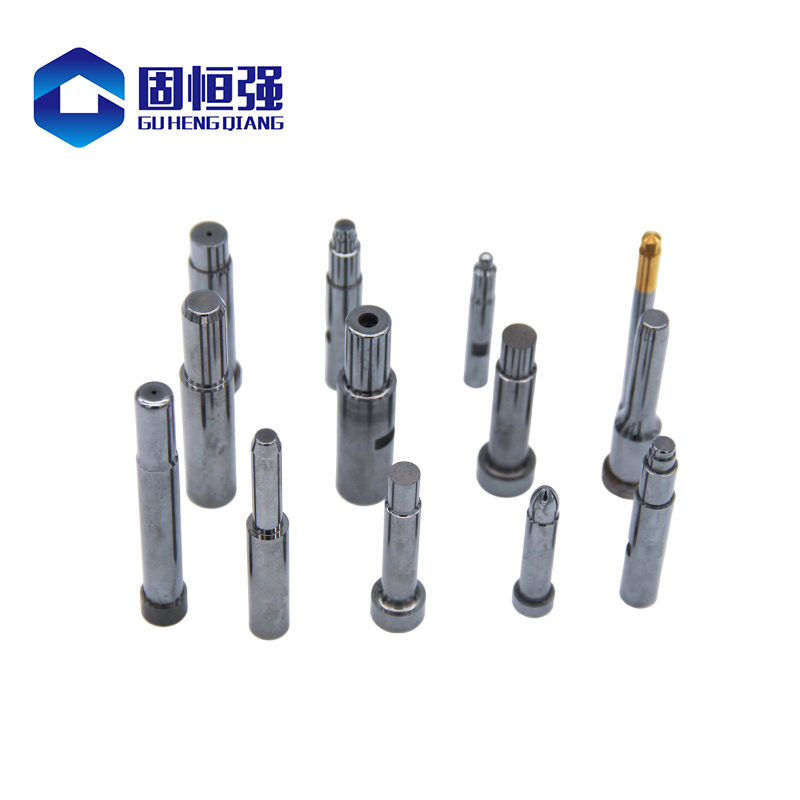

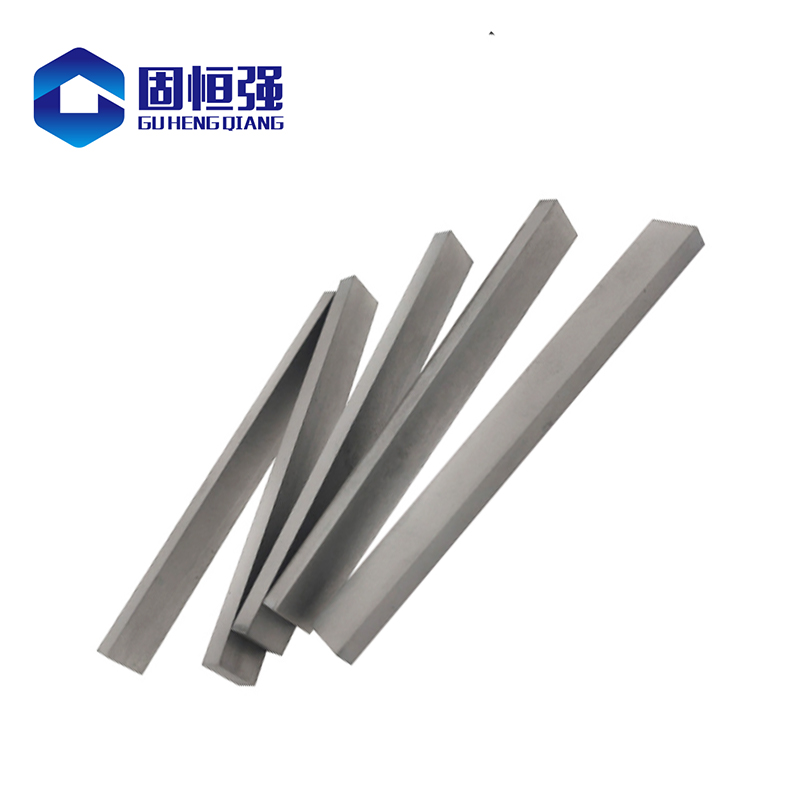

The feature of our products: High strength, high wear resistance, high precision, high temperature resistant and high corrosion resistant.

Cemented Carbide Grade

Why to choose us

1.Long service life. It is 15-20 times the service life of high-speed steel.

2.High Surface Finish. The slit product finish is good, no matter how long, the slit products burrs are controlled between 0.001-0.015mm.

3.Cost-effective. Compared with Japanese and German products, our products have high cost performance.

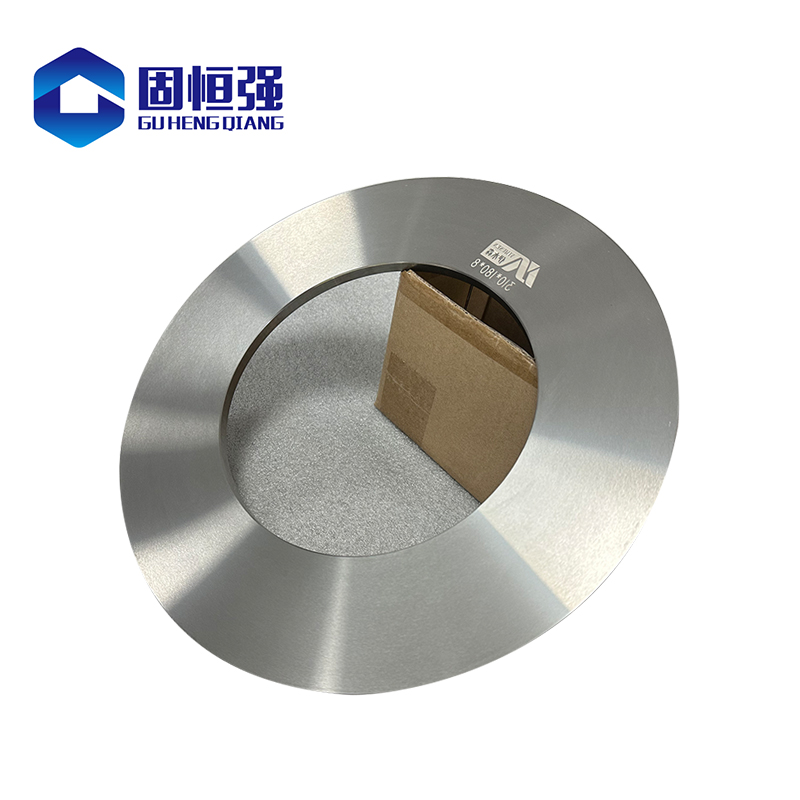

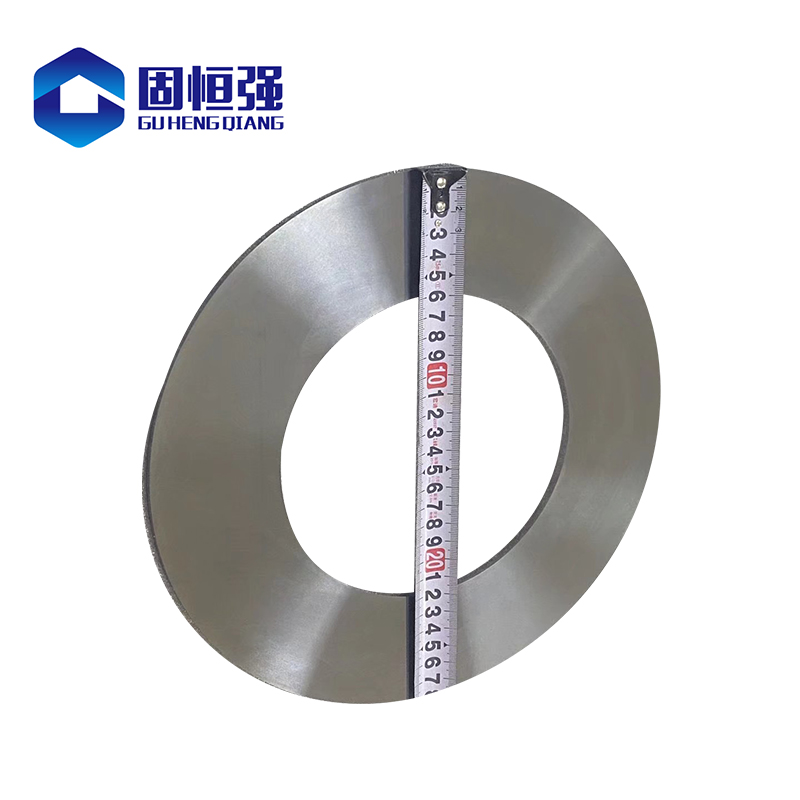

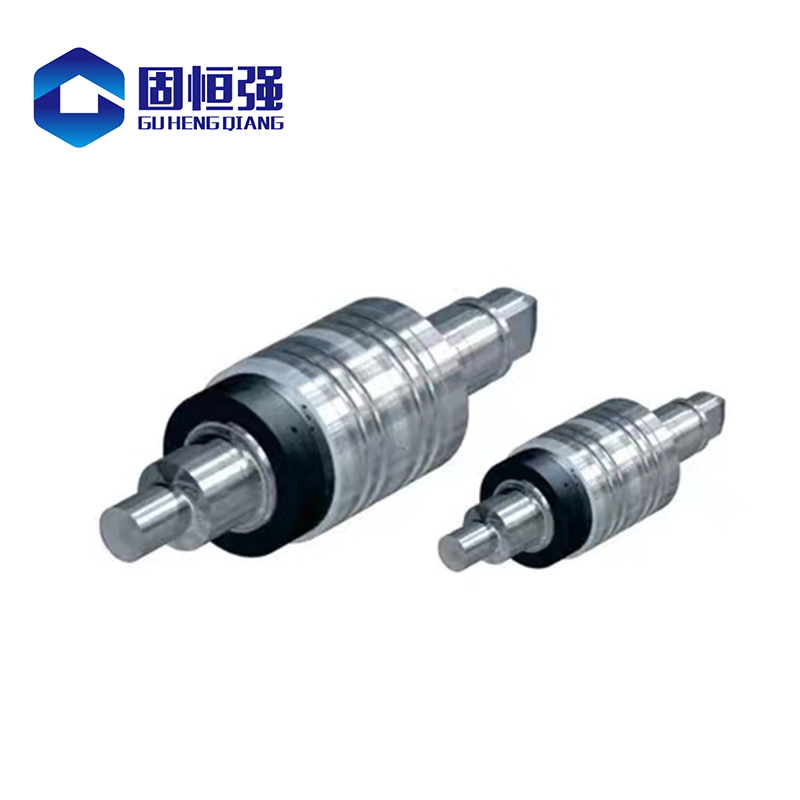

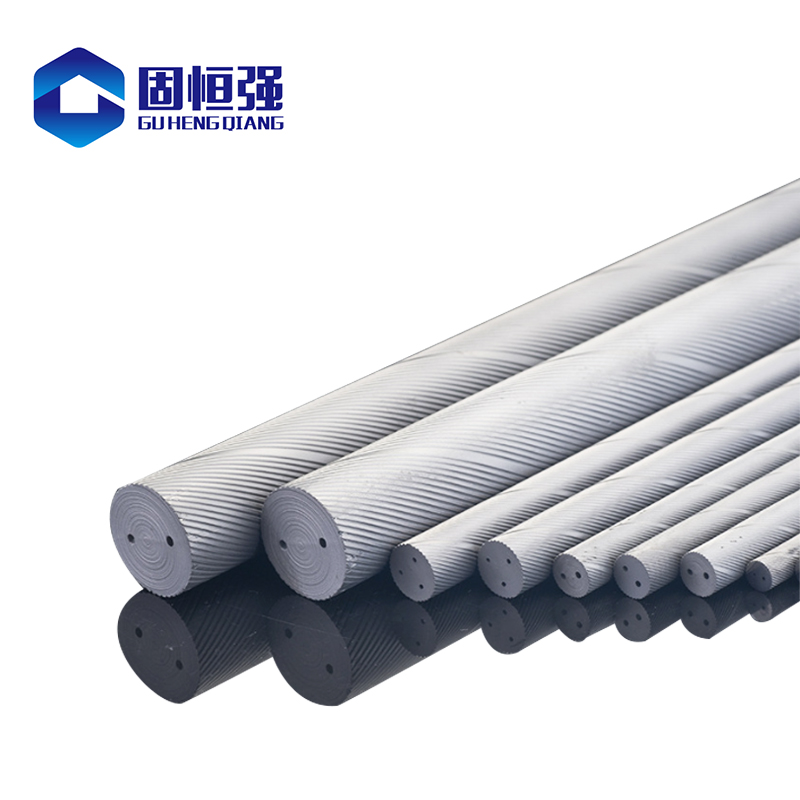

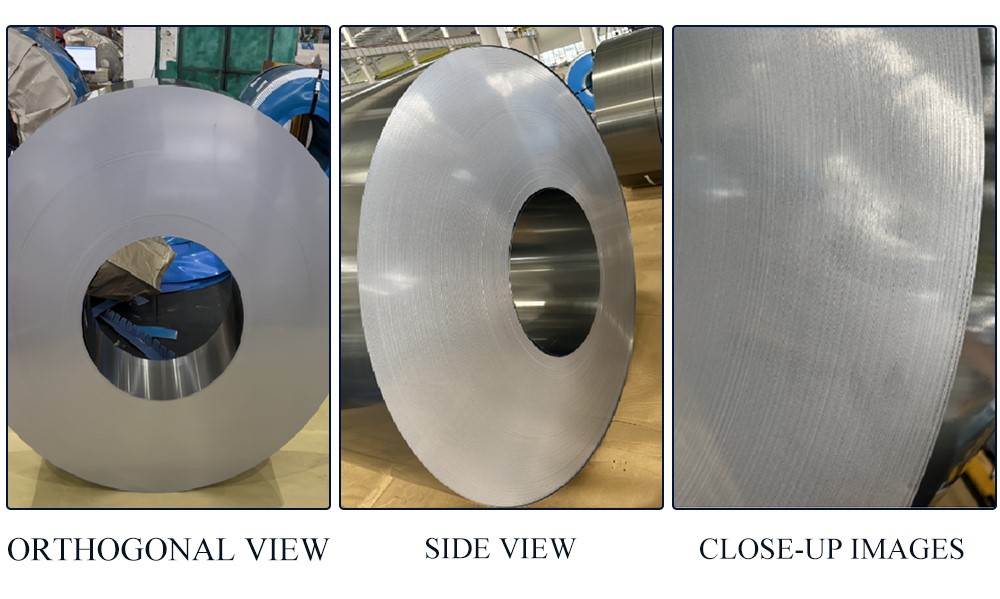

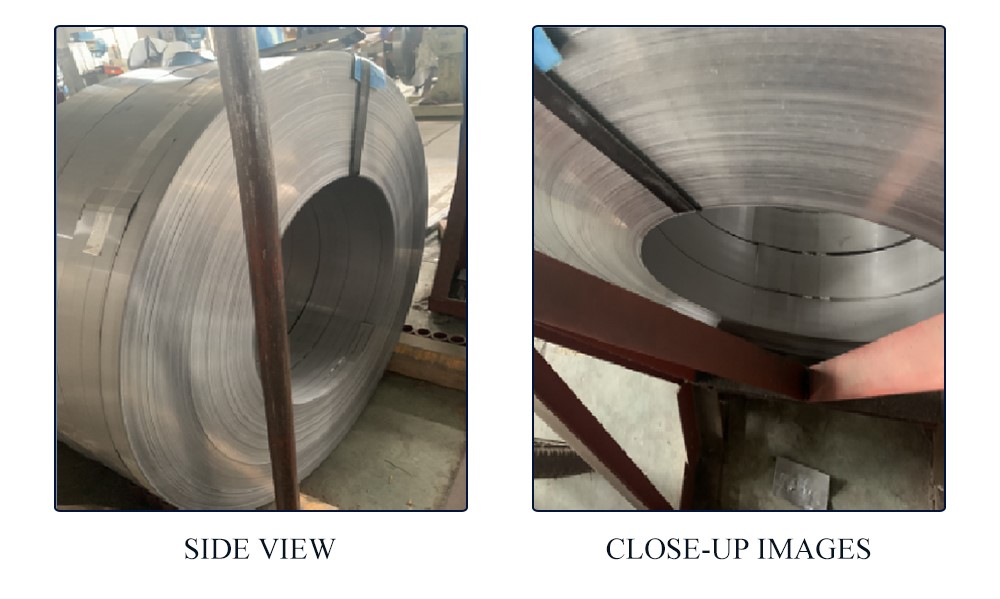

Images of Slitting Non-oriented Steel New Energy Materials

1.Slit 0.3mm New Energy Materials

2.Slit 0.3mm Transformer Materials

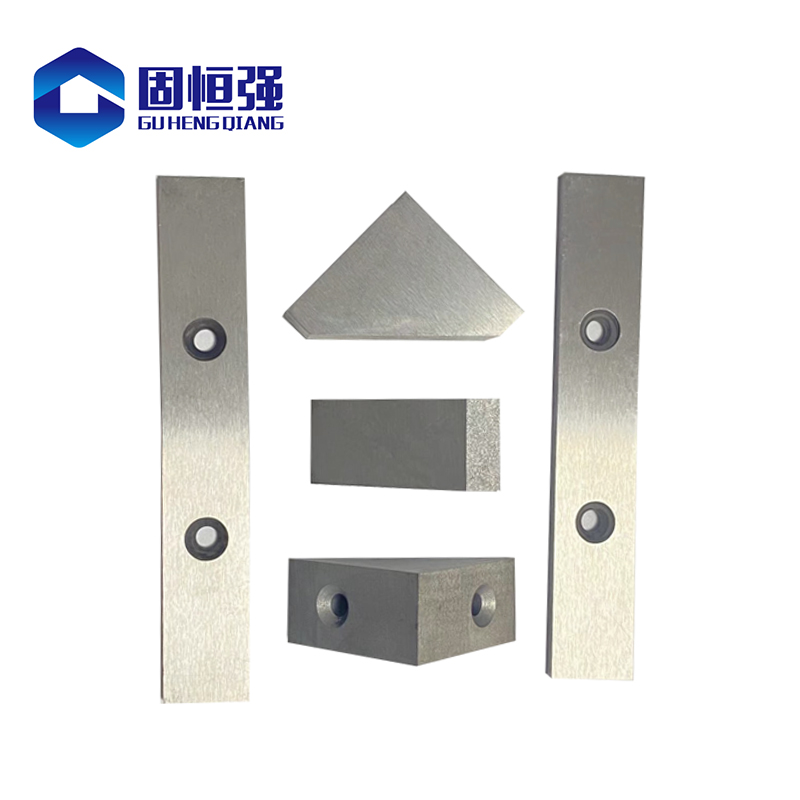

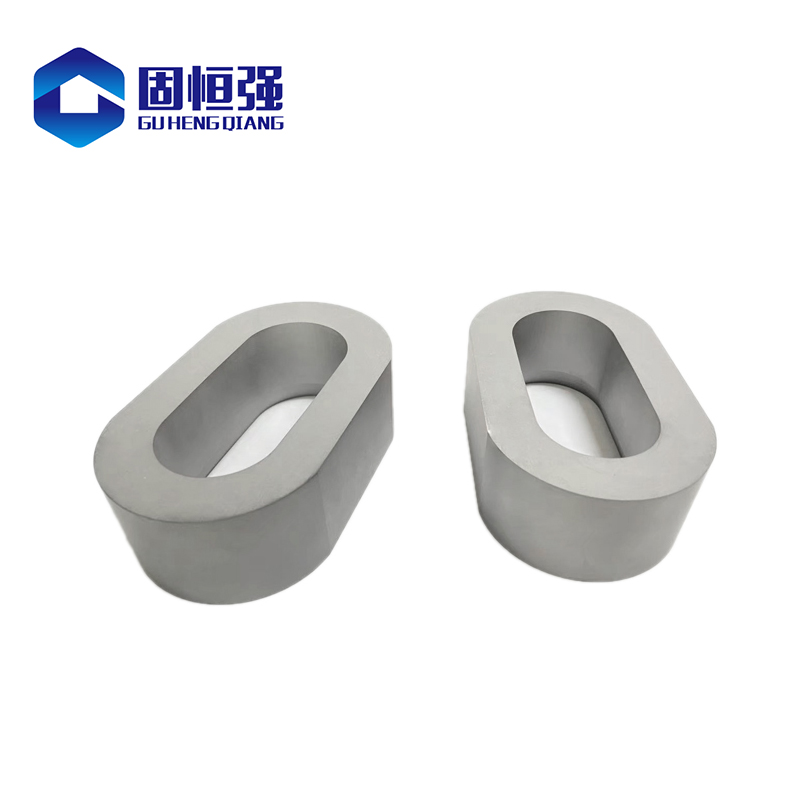

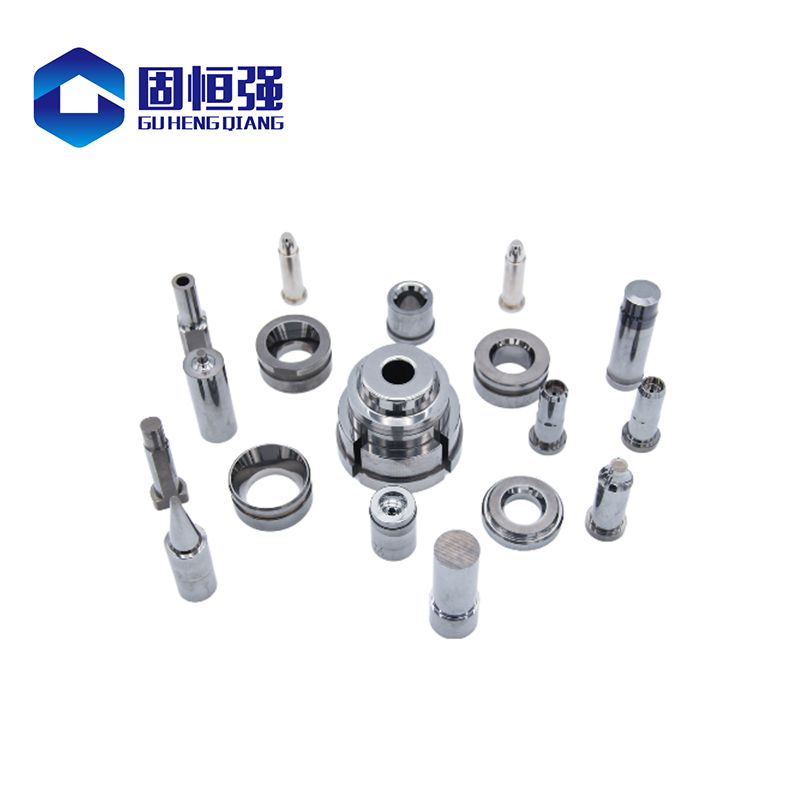

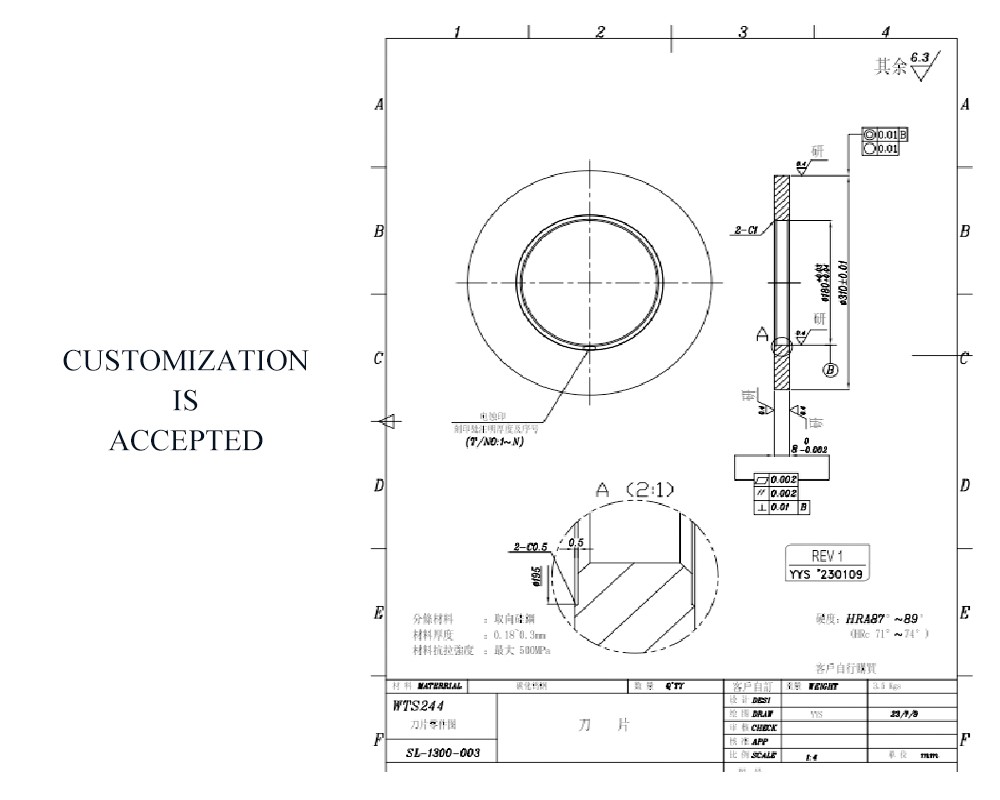

Reference Drawing

FAQ

Q1. Are you a manufacturer?

A: Yes, we are. We have the best factory to produce for you,could guarantee the price is the most competitive.

Q2. What is your terms of payment?

A: T/T 50% as deposit, and 50% balance before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. How about your delivery time?

A: Lead time as fast as 7-15 days!

Q4. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.Our production is based on ISO9001,we have more than 10 years experience of QC team and strictly quality control system in our production process.

Q6. What about the package?

A.It can make as the you need and depend on the products shapes. Generally, we can provide iron drum, carton, wooden case, and bag packages.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.