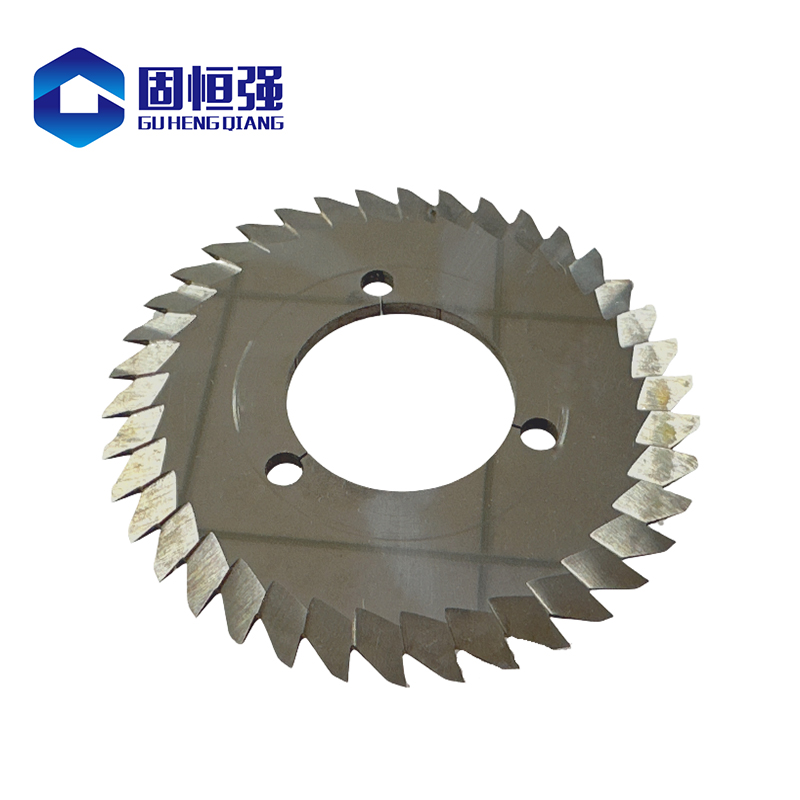

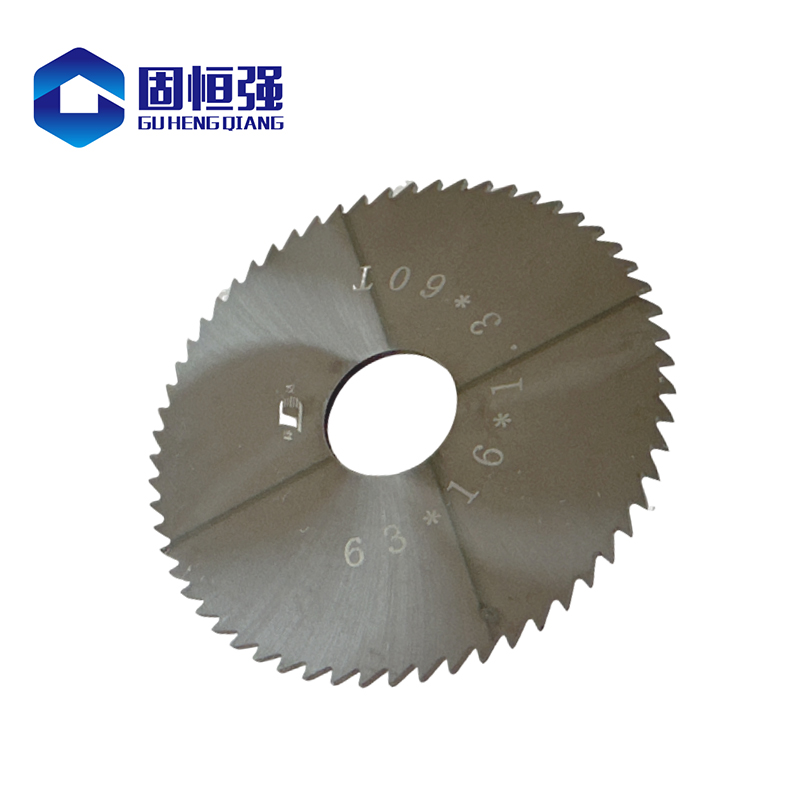

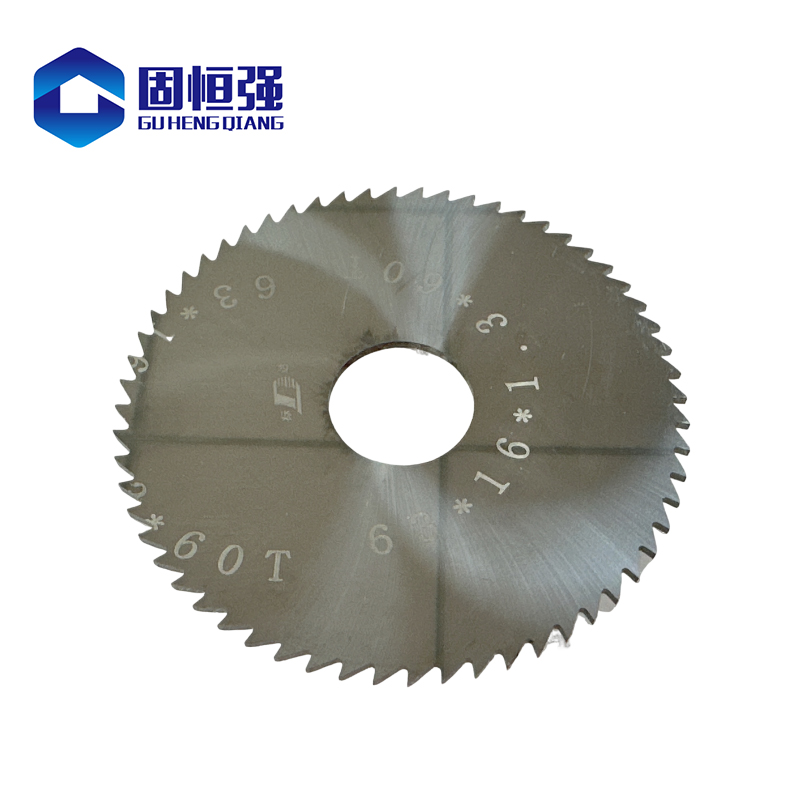

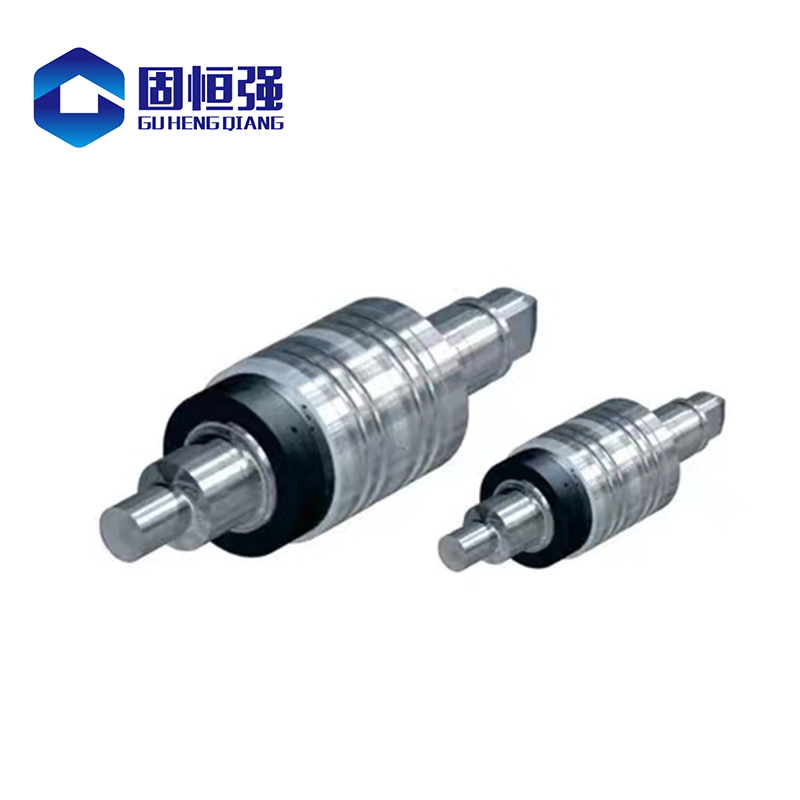

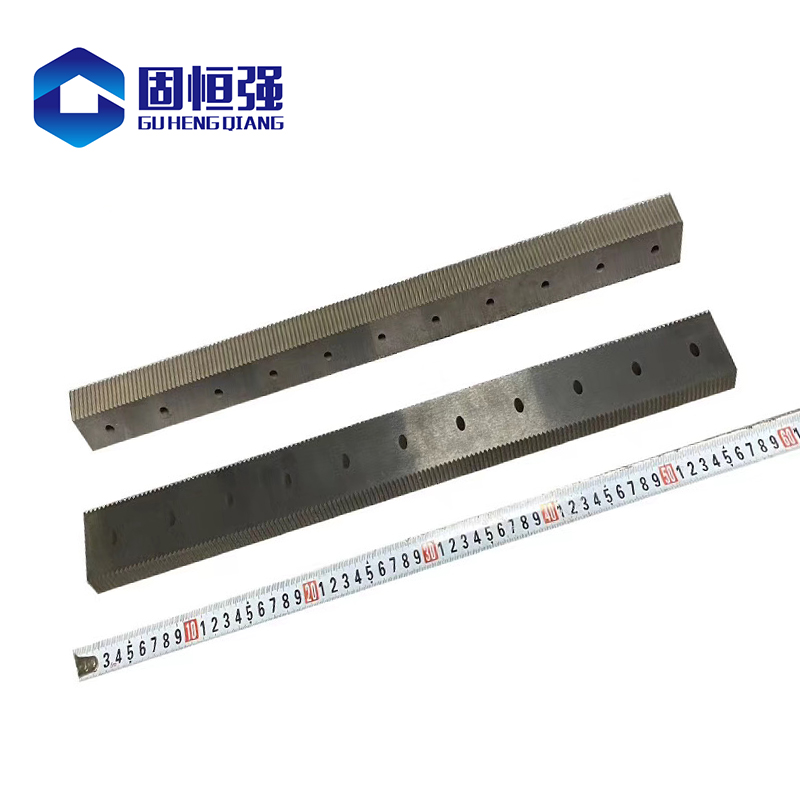

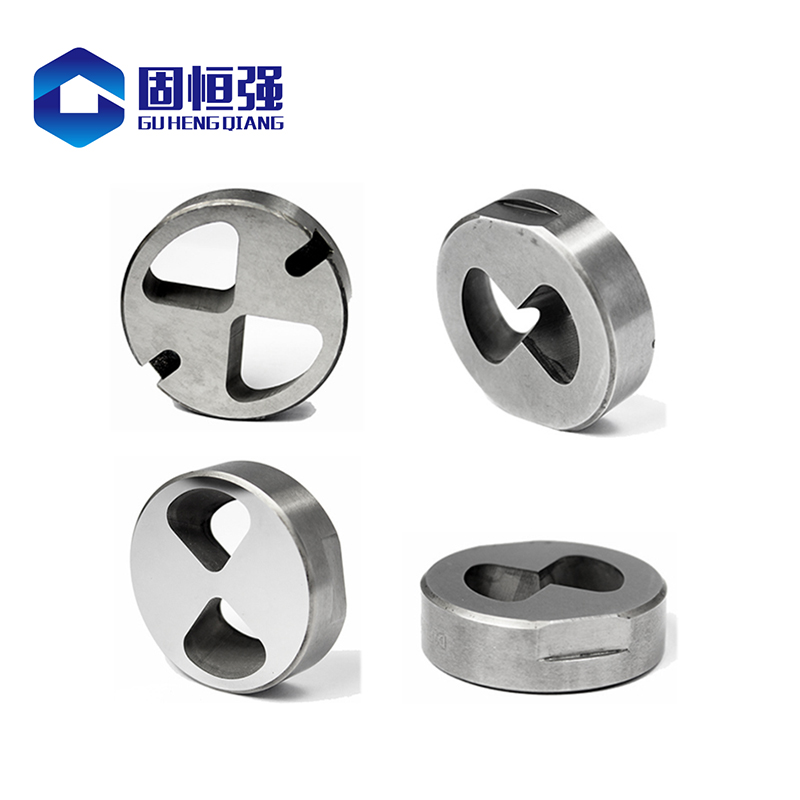

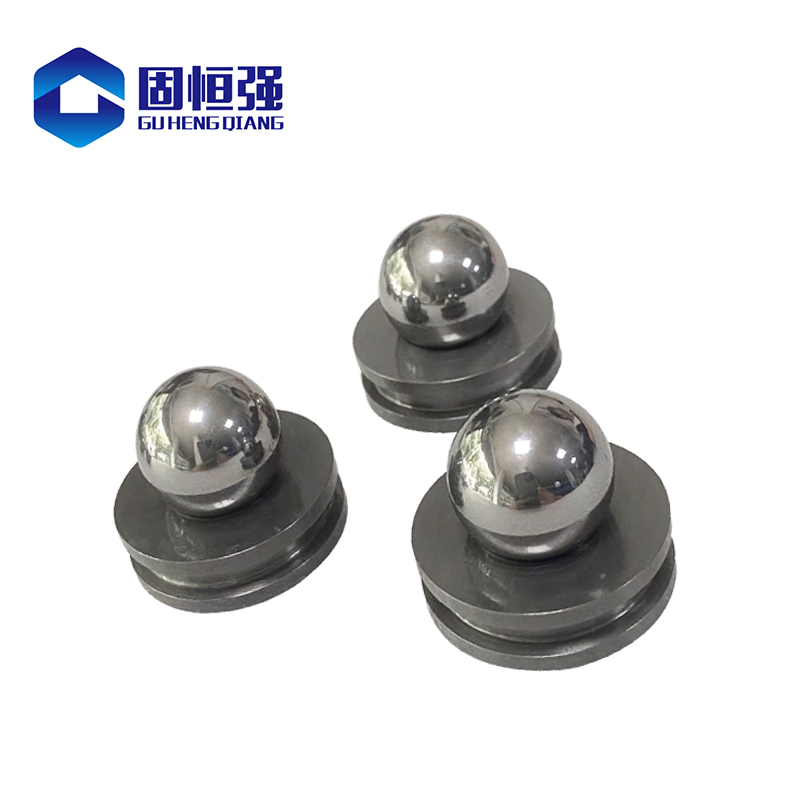

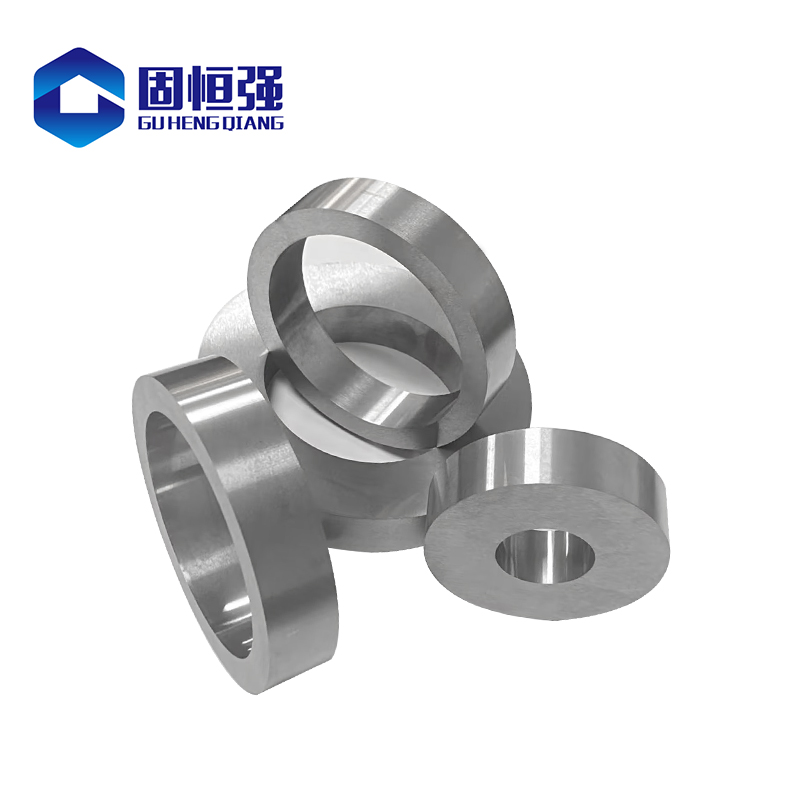

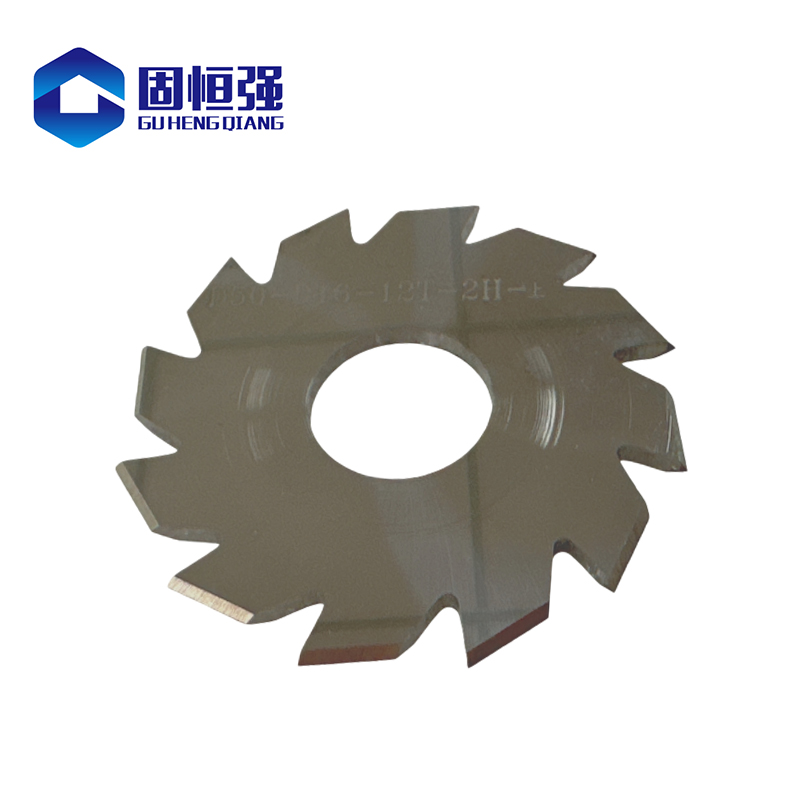

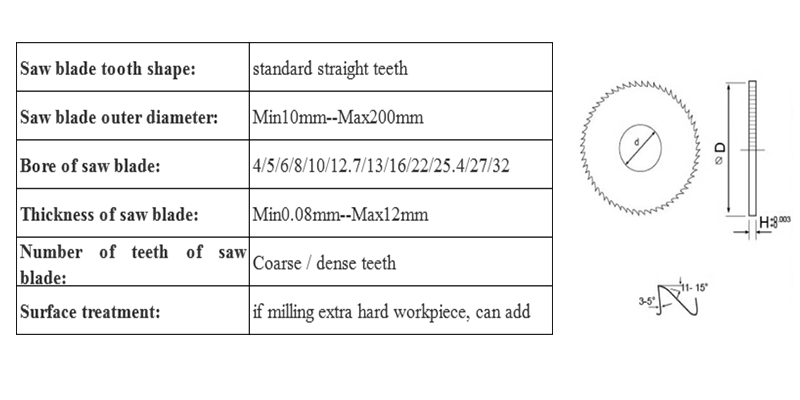

Customised Integral Carbide Tipped Saw Blades

Product Description

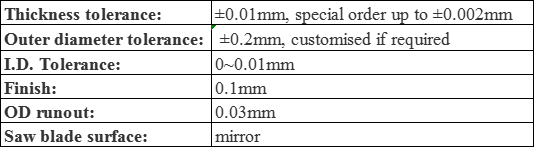

Integral Carbide Tipped Saw Blades Accuracy Standard:

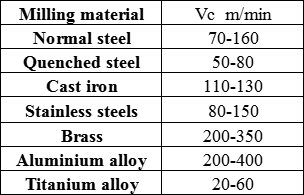

Integral Carbide Tipped Saw Blades Application Reference:

Note: The following parameters are for reference only, please adjust them according to your production.

The above table is a few different materials to be milling the whole carbide saw blade milling cutter can choose the tooth milling line speed Vc (metre/minute) (m/min) range, understand the milling cutter outer diameter D (mm) and the tooth milling line speed Vc, you can calculate the milling cutter shaft speed n (rev / min):

Vc×1000

n= π×D

The amount of feed per tooth is generally set between 0.006-0.025 is appropriate.

Knowing the feed rate per tooth St (mm / tooth), the number of milling cutter teeth T, can be calculated to feed the speed VE

Vf(mm/minute) =St×T×n

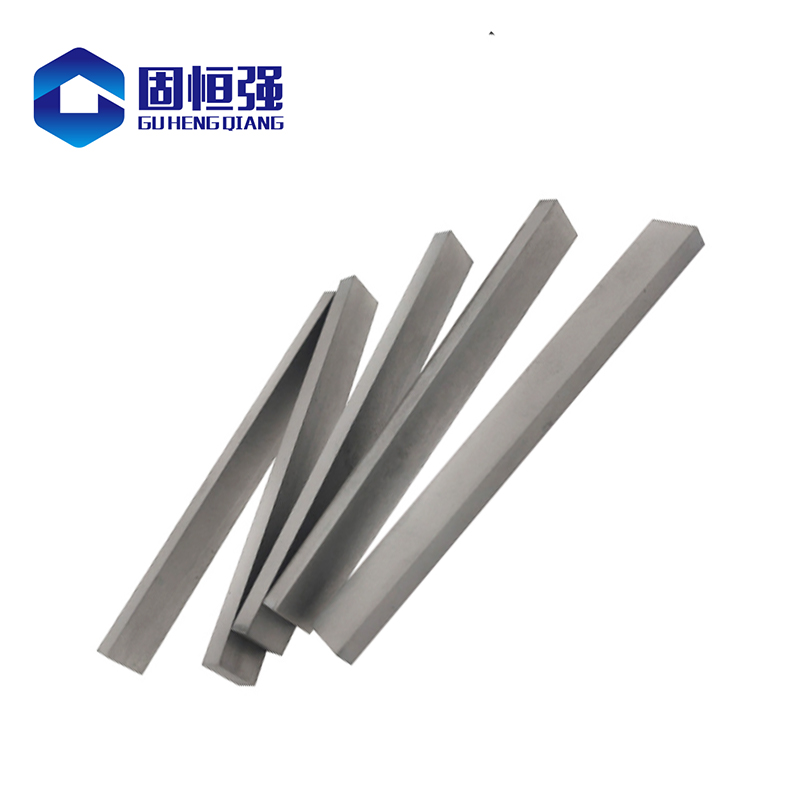

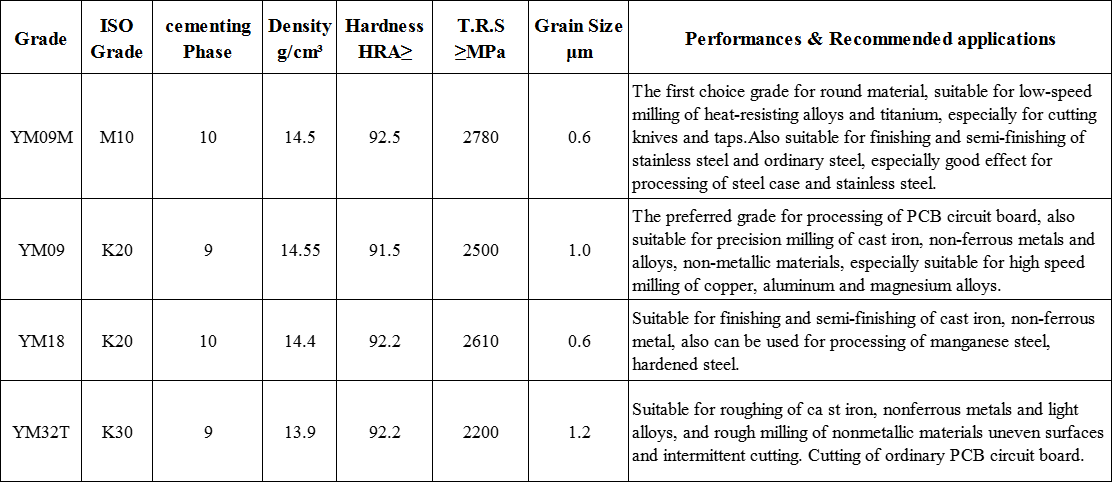

Integral Carbide Tipped Saw Blades Grades

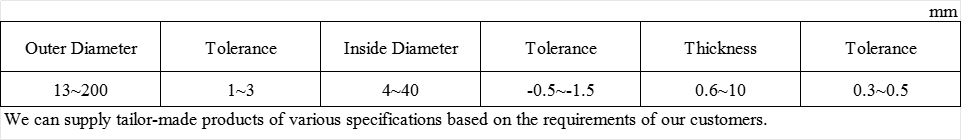

Integral Carbide Tipped Saw Blades Size

Selected Specifications and Dimensions of Integral Carbide Tipped Saw Blades Noted

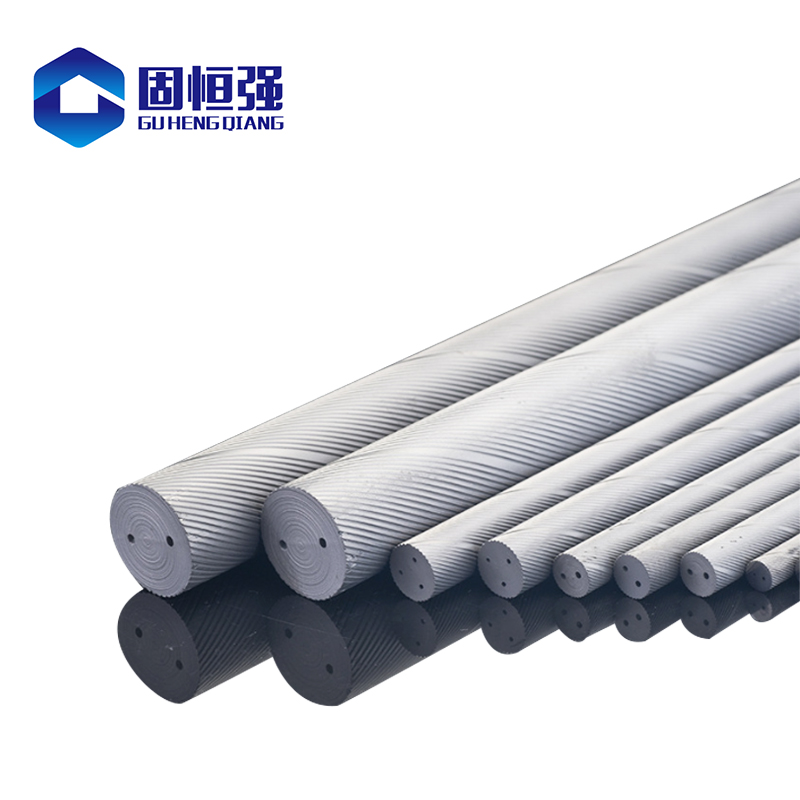

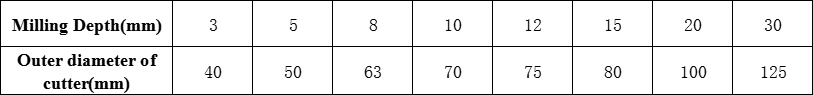

Selection of outer diameter: Generally, the outer diameter can be set according to the milling depth, which can be selected by referring to the following table, but when the installation space of saw blade milling cutter is restricted, the outer diameter can also be reduced appropriately.

When the outer diameter is selected, and then determine the bore diameter, and then select the number of teeth T and the nature of the material to be milled, the finish of the surface to be processed and the thickness of the milling cutter, when the milling cutter is thinner should be selected to have a normal life of a greater number of teeth.

Thickness can be applied to how thin with the outer diameter, the thickness of the beginning of the range of sizes generally indicate that the use of the outer diameter of the thickness of the size can be achieved, for example: the outer diameter of 60mm, the thickness of the range of 0.5-10mm, that is, indicating that the outer diameter of 60, our company can produce saw blades can only be the thinnest to do for the 0.5mm.

When you ask for quotation of Integral Cemented Carbide Straight Tooth Saw Blade Milling Cutter, please write down the specification size (mm): O.D. x Bore Diameter x Thickness x Number of Teeth, and indicate the type of material to be cut/hardness/depth of milling.

FAQ

Q1. Are you a manufacturer?

A: Yes, we are. We have the best factory to produce for you,could guarantee the price is the most competitive.

Q2. What is your terms of payment?

A: T/T 50% as deposit, and 50% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. How about your delivery time?

A: Lead time as fast as 7-15 days!

Q4. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.Our production is based on ISO9001,we have more than 10 years experience of QC team and strictly quality control system in our production process.

Q6. What about the package?

A.It can make as the you need and depend on the products shapes. Generally, we can provide iron drum, carton, wooden case, and bag packages.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.