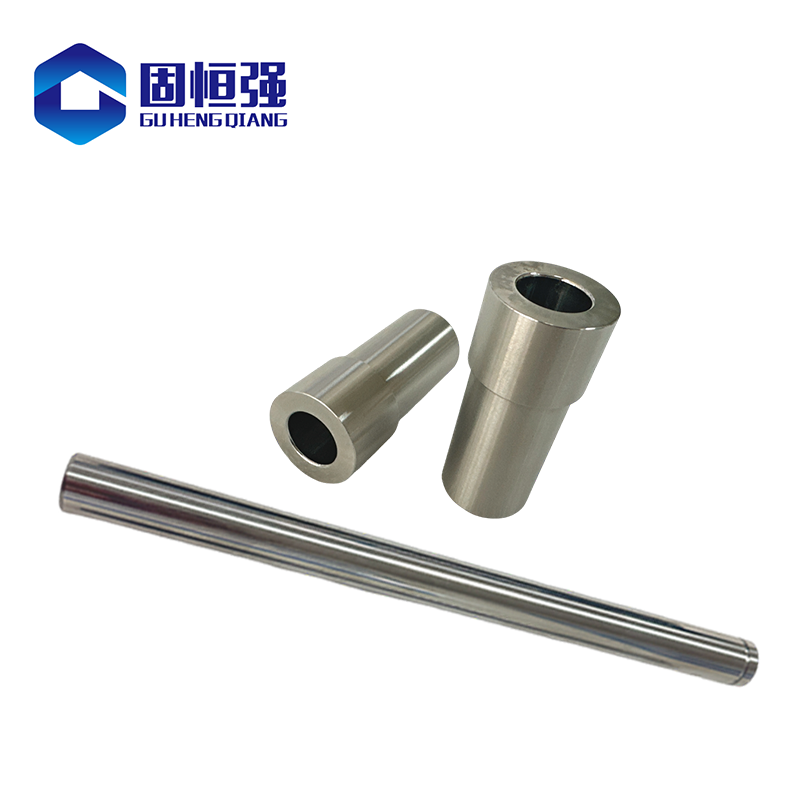

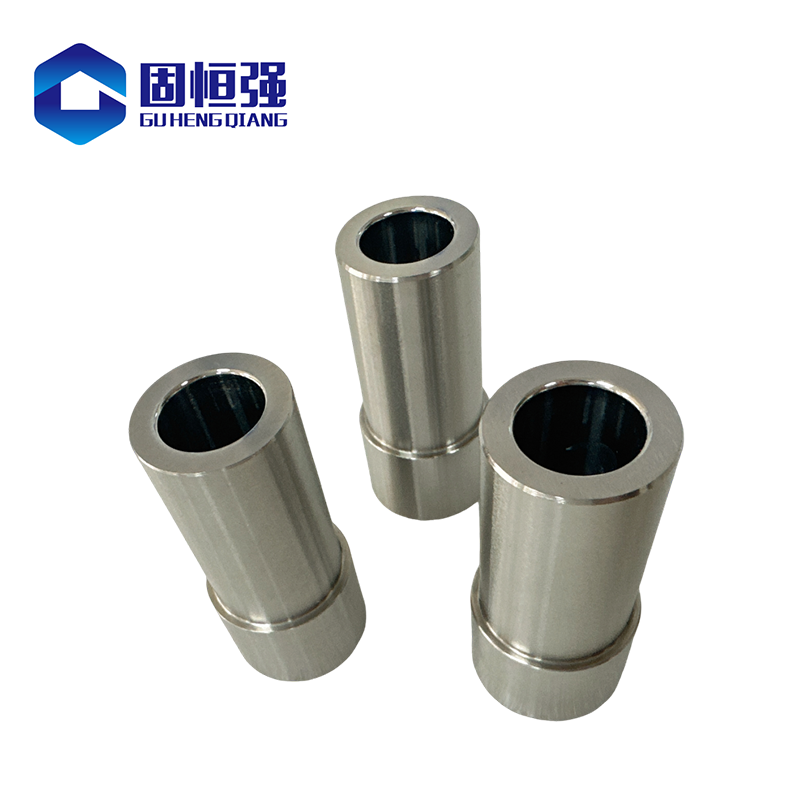

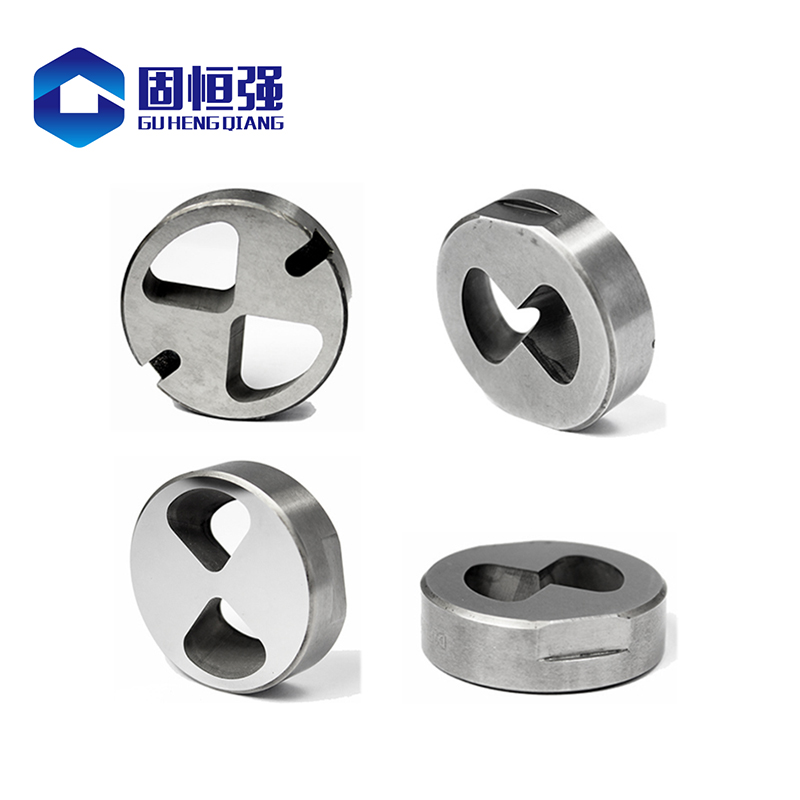

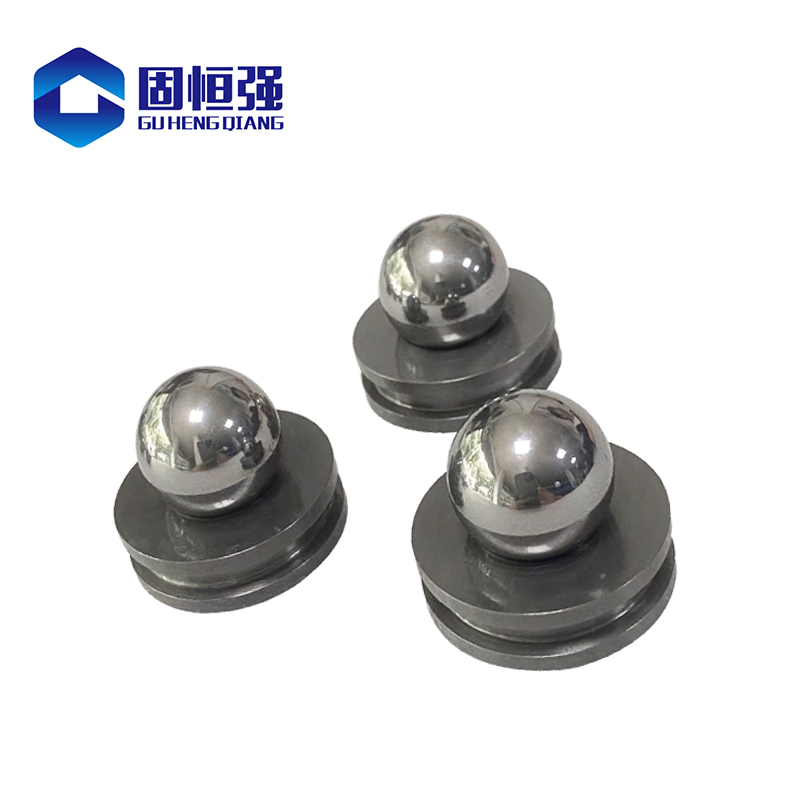

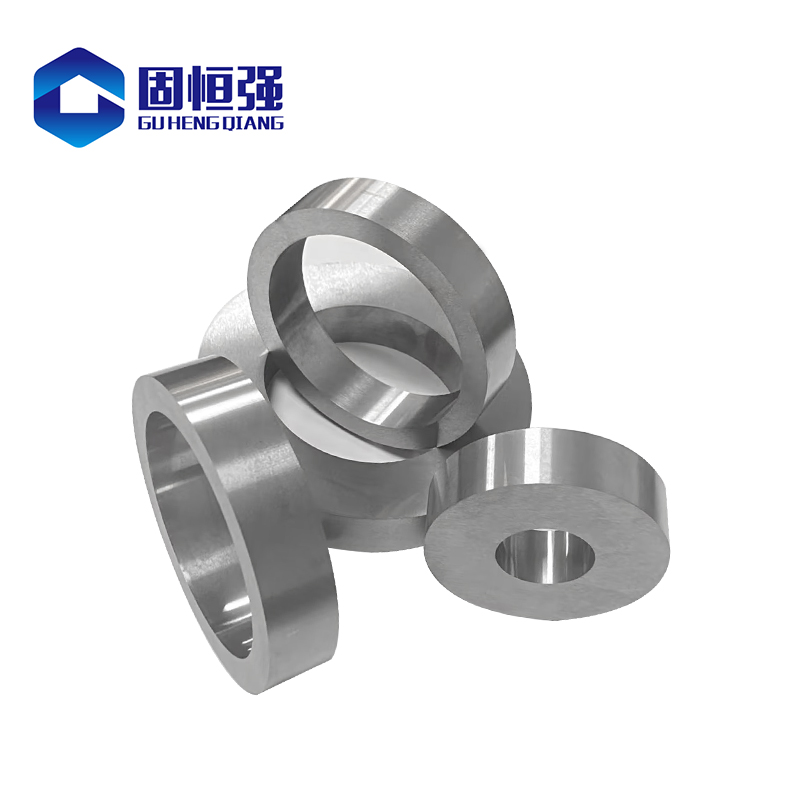

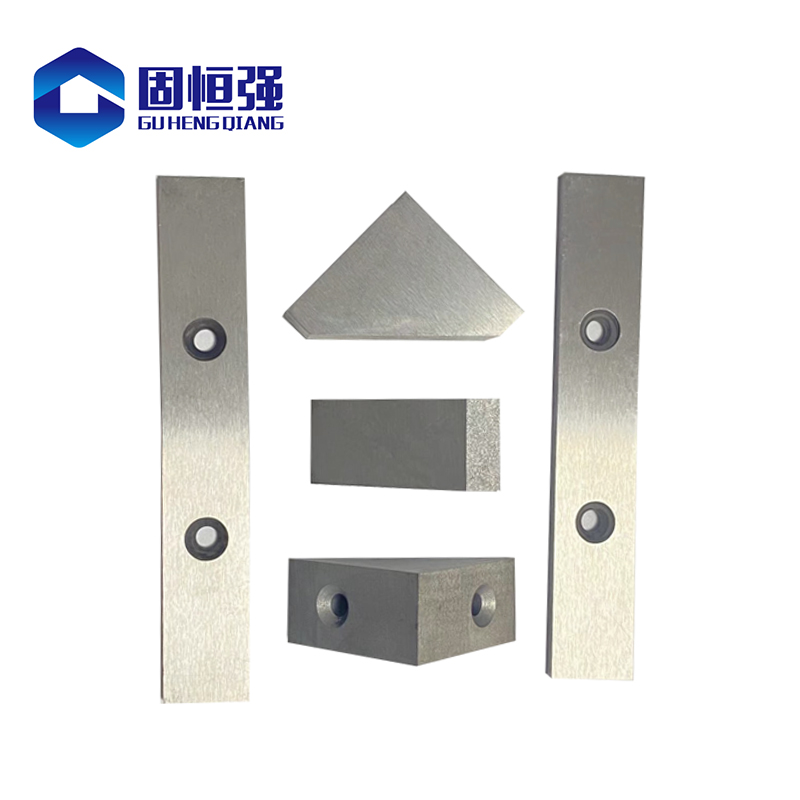

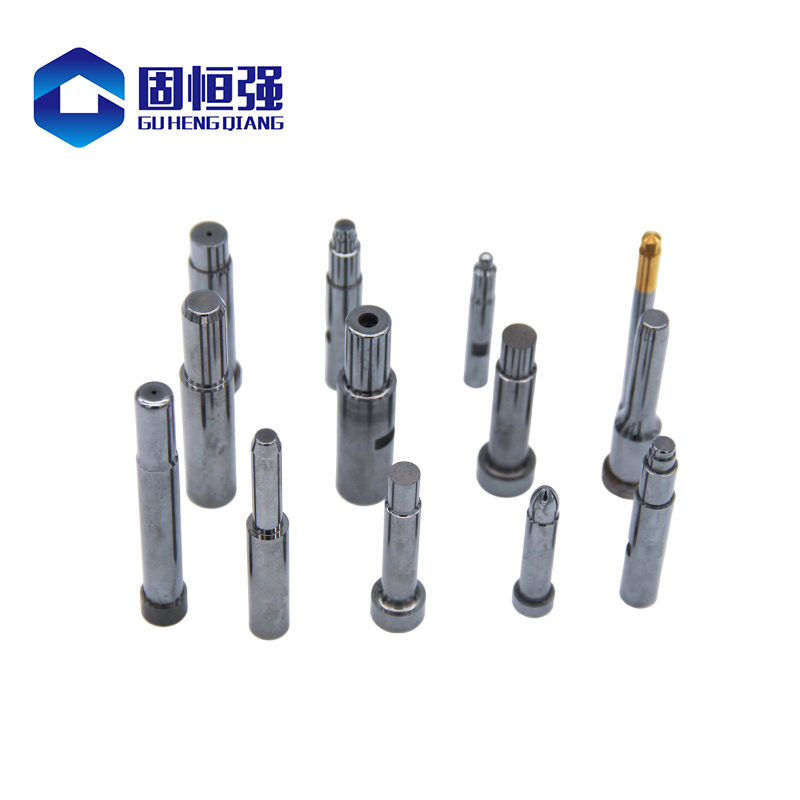

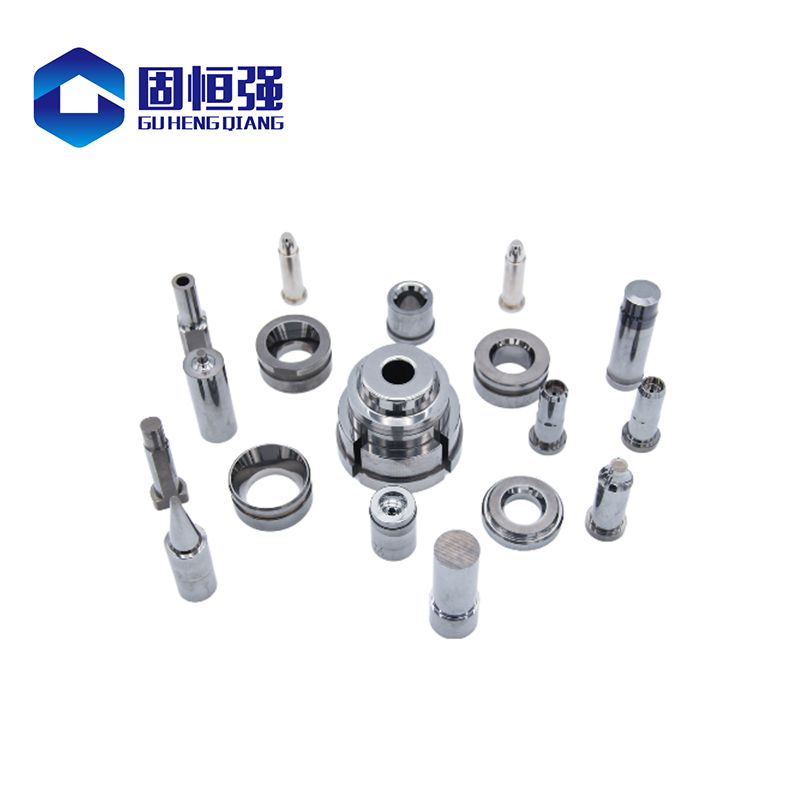

Non-magnetic Tungsten Steel Concave Mold Plunger

Introduction of Non-magnetic Tungsten Steel Concave Mold Plunger

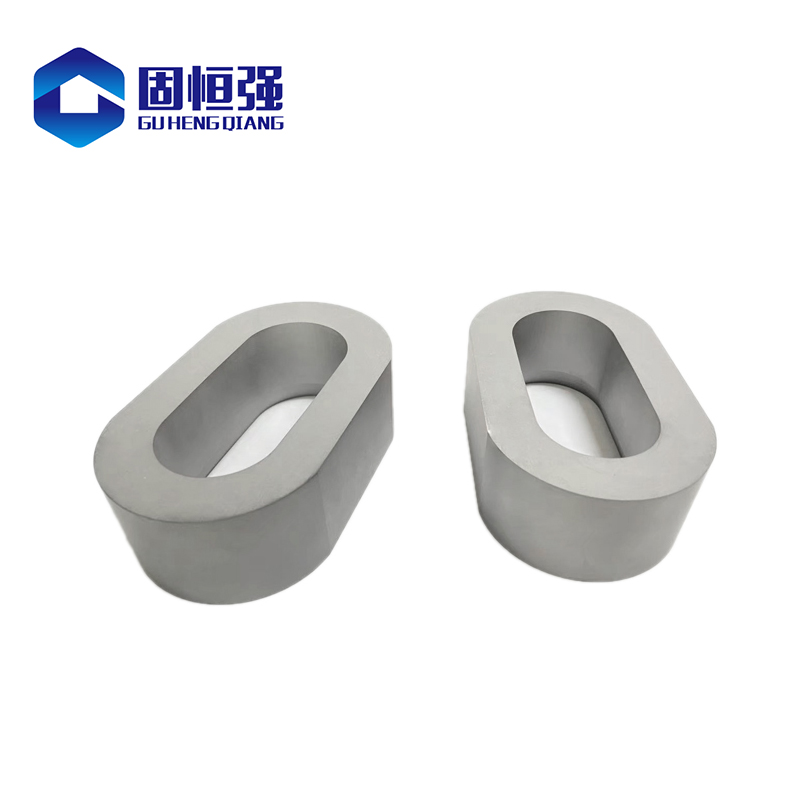

Due to the production of magnetic material molding mold requires the use of non-magnetic materials, in the past has been the use of non-magnetic steel, the mold performance is poor, low hardness, short service life, and after a period of time, the mold wall serious hair, deformation, and so on, which affects the dimensional accuracy of the magnetic material and the surface quality. Nowadays, the use of high wear-resistant, acid and alkali resistant, high temperature resistant non-magnetic cemented carbide, with its excellent performance instead of non-magnetic steel can exponentially improve the efficiency and reduce production costs, is the production of magnetic materials manufacturers of choice.

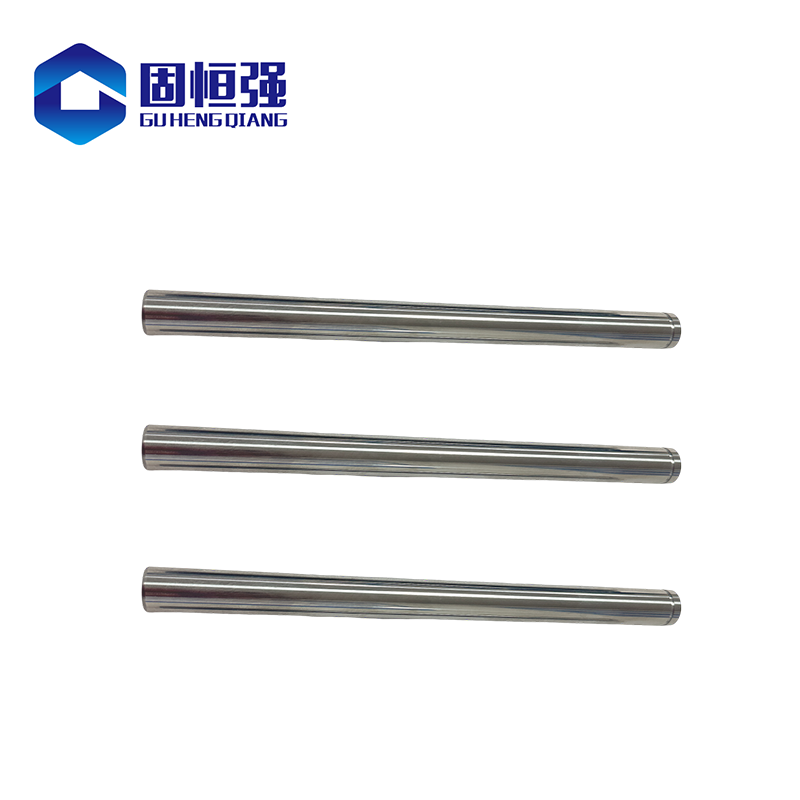

Processing technology: kneading honing, also known as abrasive flow processing, this process is the use of a semi-solid abrasive abrasive, under the effect of kneading honing machine, so that the abrasive in the exterior of the processed parts for reciprocating motion, the parts of the various cavities and interspersed with the aperture and the edge of the edge of the parts to be grinded and polished, inverted garden angle deburring of a new type of technology.

Application Areas of Non-magnetic Tungsten Steel Concave Mold Plunger

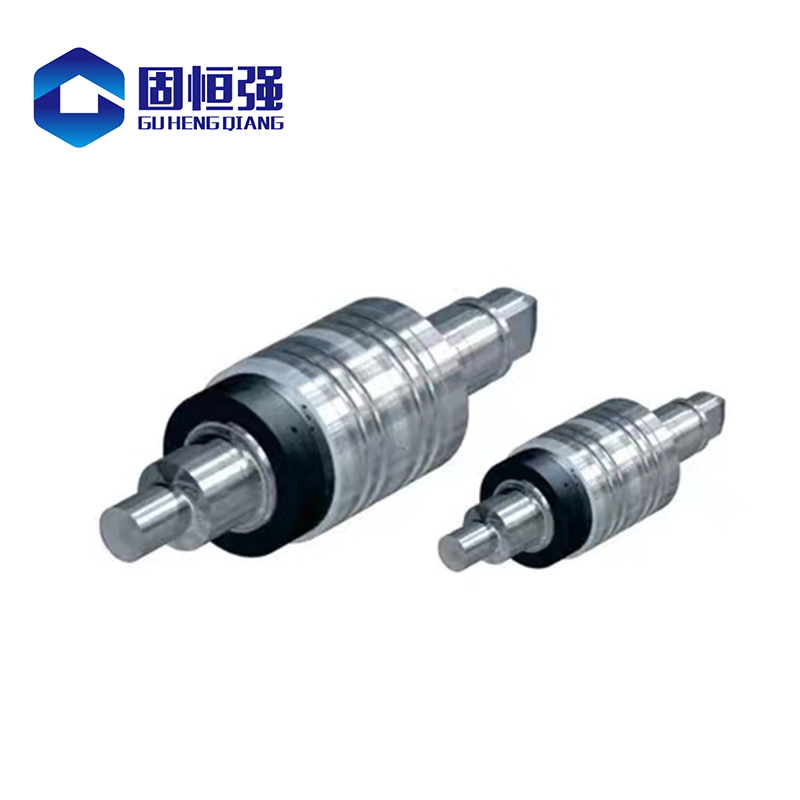

1. Suitable for punching metal magnetic materials (inductor coils, transformers, relay cores) and silicon steel sheets.

2. Suitable for molding and stamping of five types of magnetic powder materials: paramagnetic material, antimagnetic material, ferromagnetic material, submagnetic material and antimagnetic material.

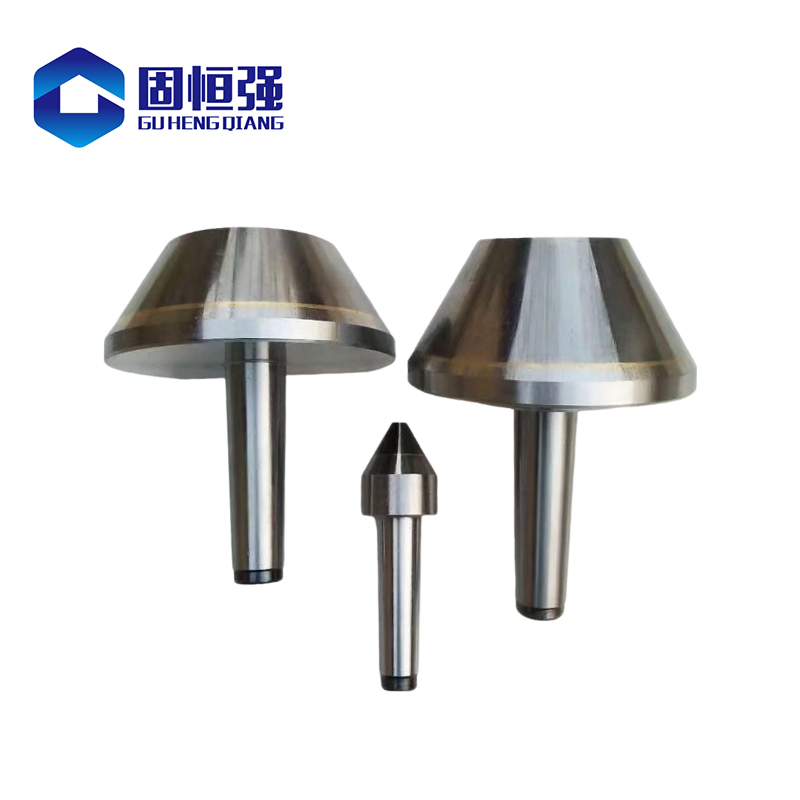

3. Applied to battery mold burning nozzle, tungsten-molybdenum gripper glass cutter, and stamping battery shell, toothpaste skin molds

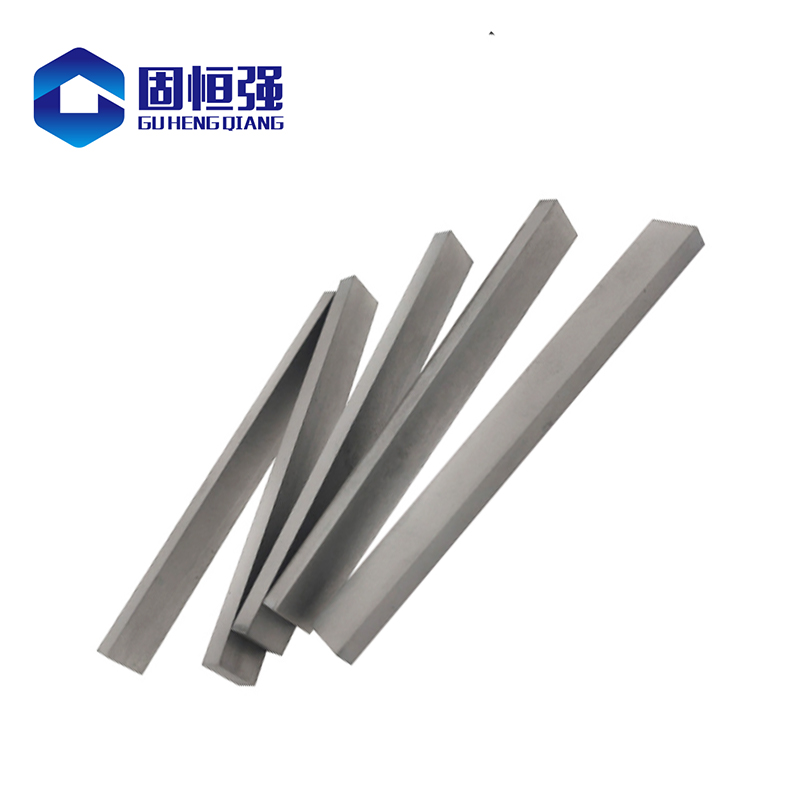

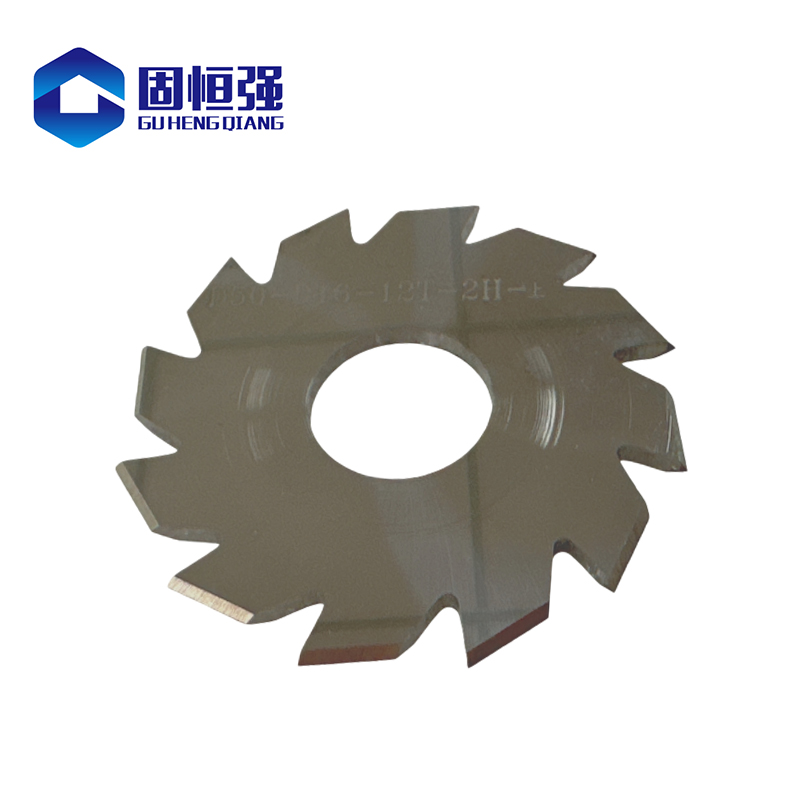

4. All kinds of metal and non-metallic powder molding and stamping, compression rate of steel rods, steel pipe stretching, the amount of larger stress under the work of the top forging, piercing and stamping molds, machine parts, mold cores, the production of stamping molds, such as the stamping of watch parts, musical instruments spring sheet, etc.

5. Stamping molds for bullets and cartridge cases

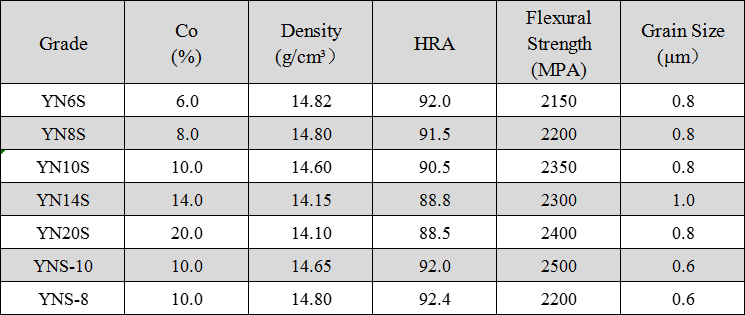

Non-magnetic Tungsten Steel Concave Mold Plunger Grade Introduction

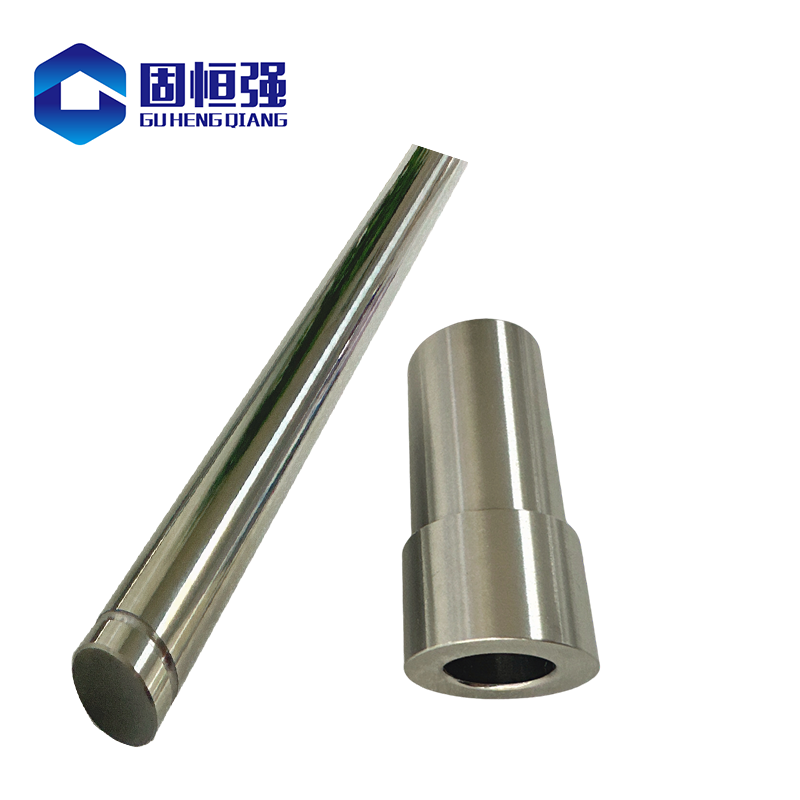

Non-magnetic Tungsten Steel Concave Mold Plunger Customized Instructions

1. Customized according to your samples or drawings;

2. According to your working conditions to provide you with grades and provide design solutions, with professional solutions to the actual needs of customers

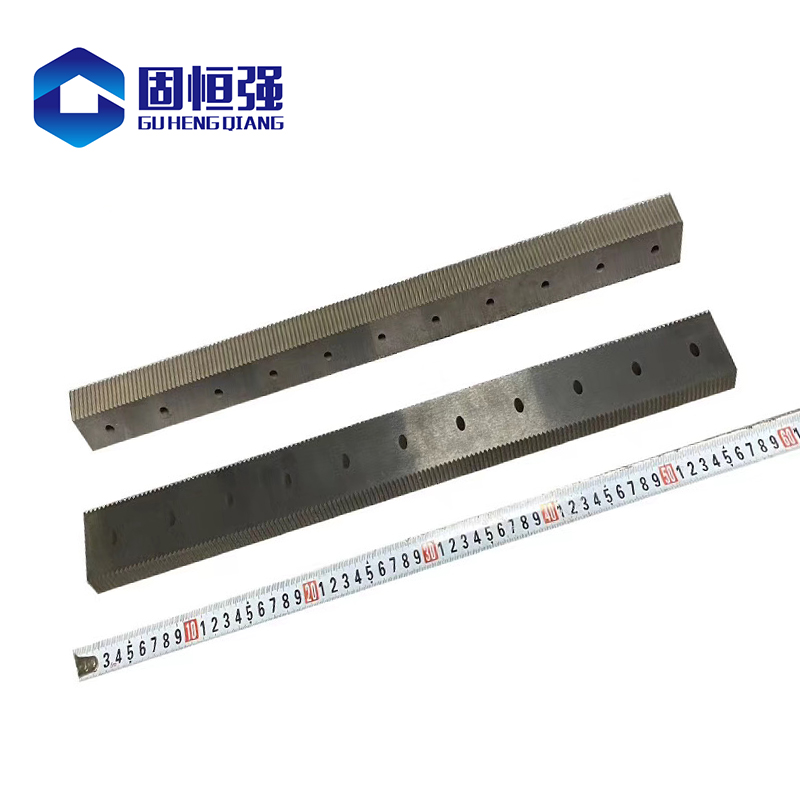

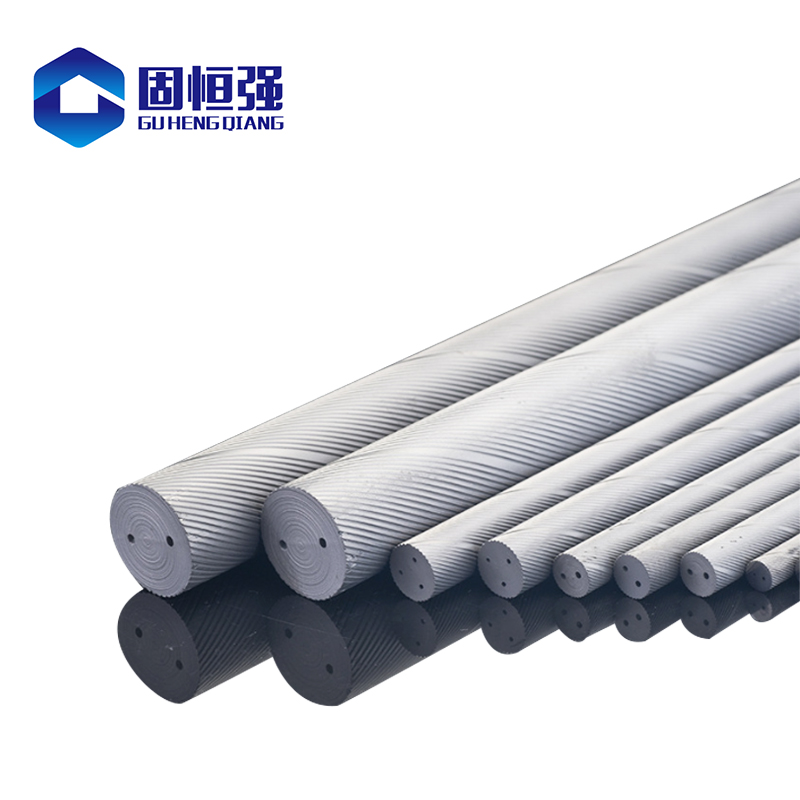

3. Non-magnetic tungsten steel by 1300 ~ 1450 ℃ high-temperature and high-pressure vacuum sintering made of good bending strength and high hardness, with non-magnetic tungsten steel made of stamping mold is non-magnetic steel stamping mold service life of dozens of times.

4. Non-magnetic tungsten steel press molding die in the pressing process will not produce mold wall hair phenomenon, there is no non-magnetic steel mold cavity deformation phenomenon, non-staining phenomenon, can better protect the dimensional accuracy of the magnetic material blank and surface quality.

5. High hardness: 88.0~92.5 HRA, depending on the application requirements.

Our company produces cemented carbide products, a variety of varieties and specifications, welcome to order! For you to comprehensively solve the production problems!

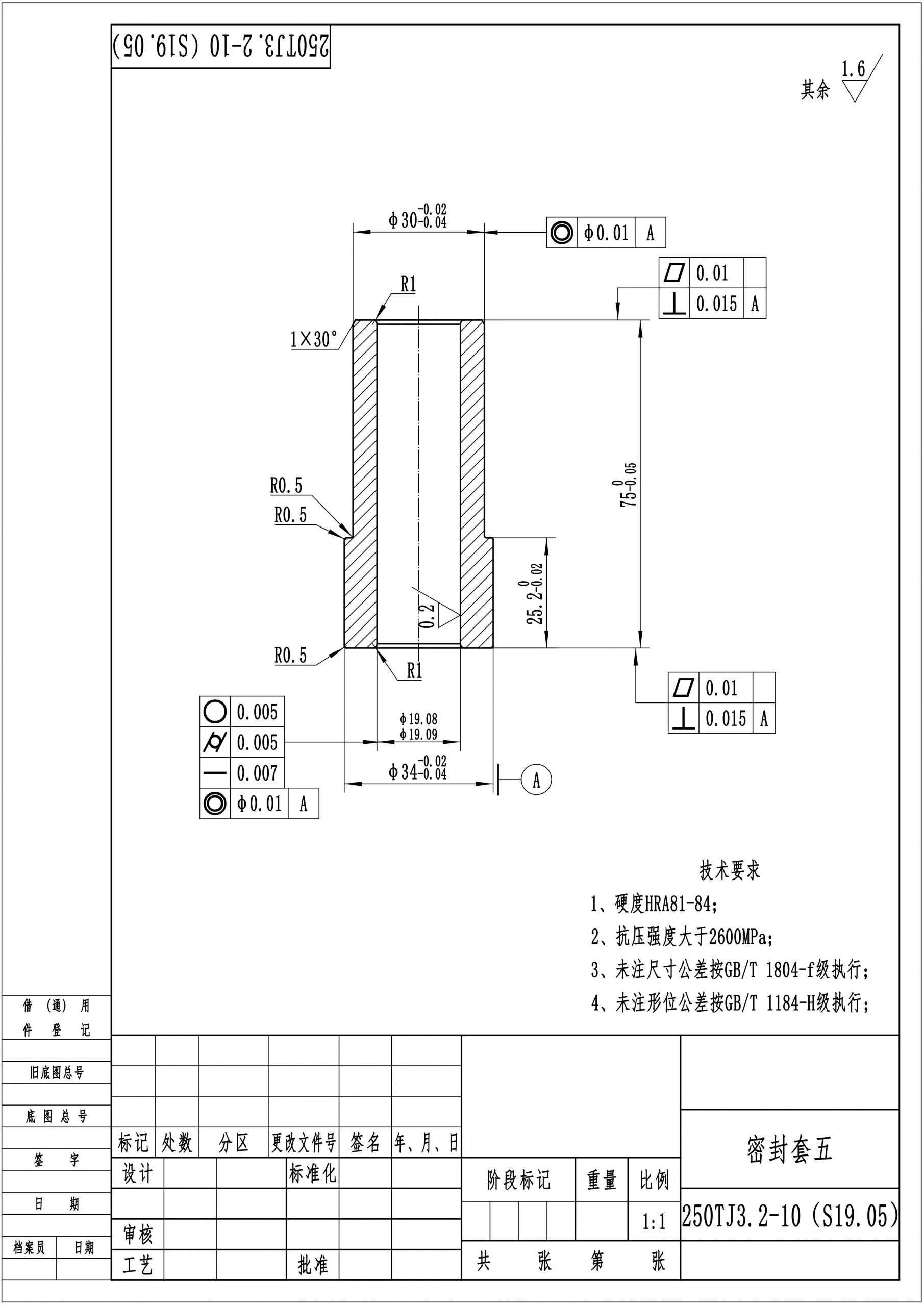

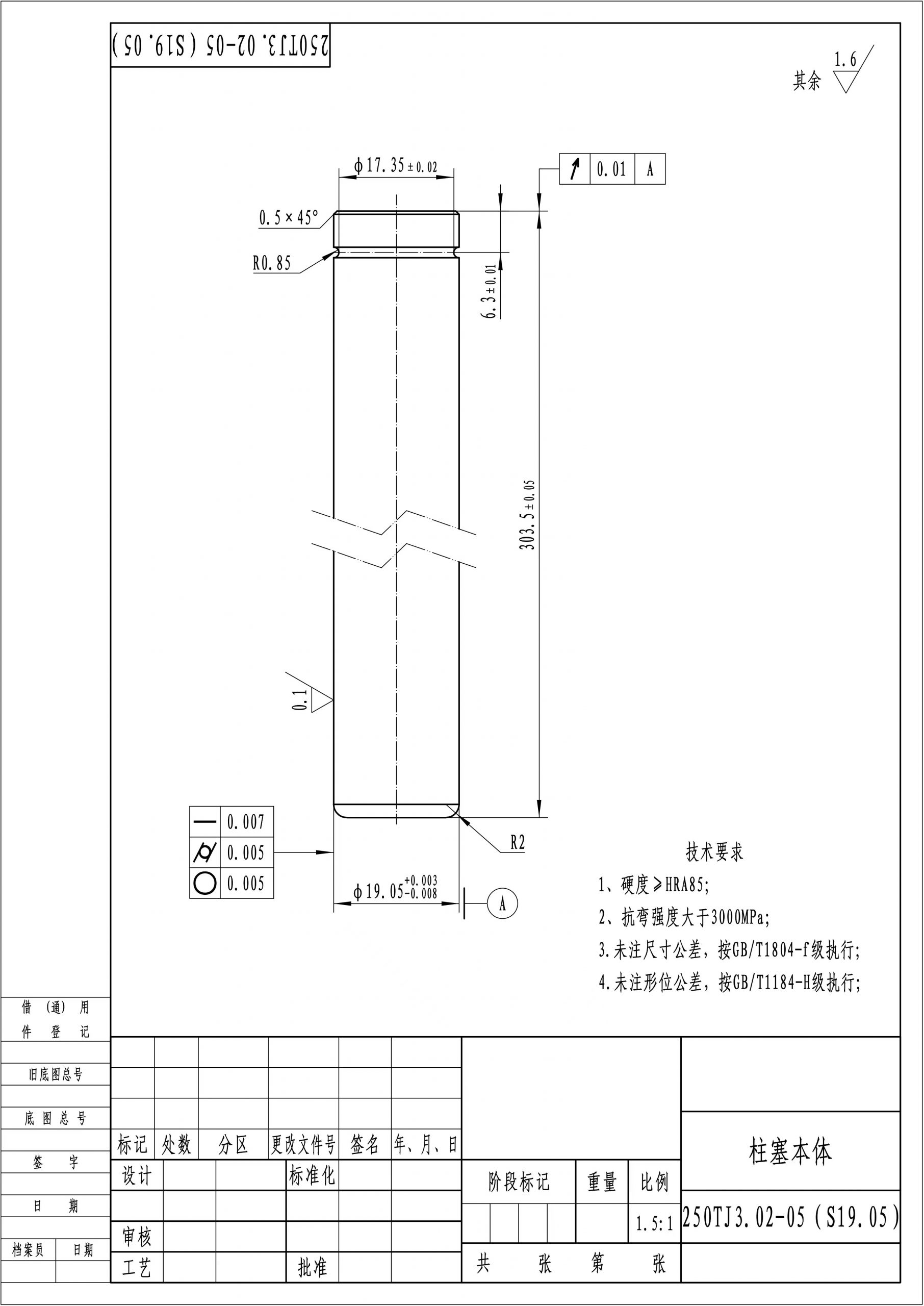

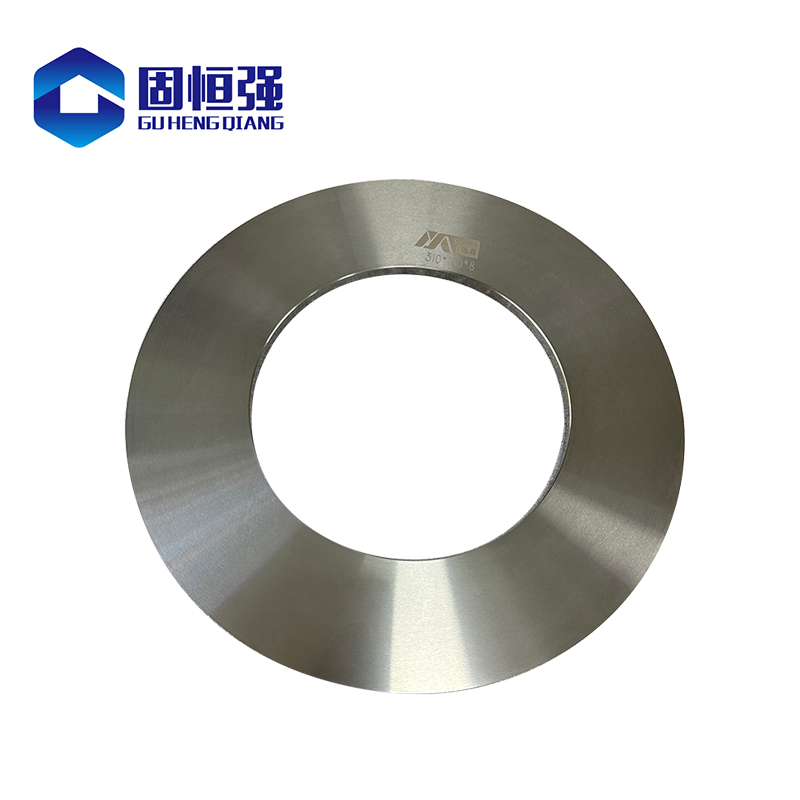

Reference Drawings