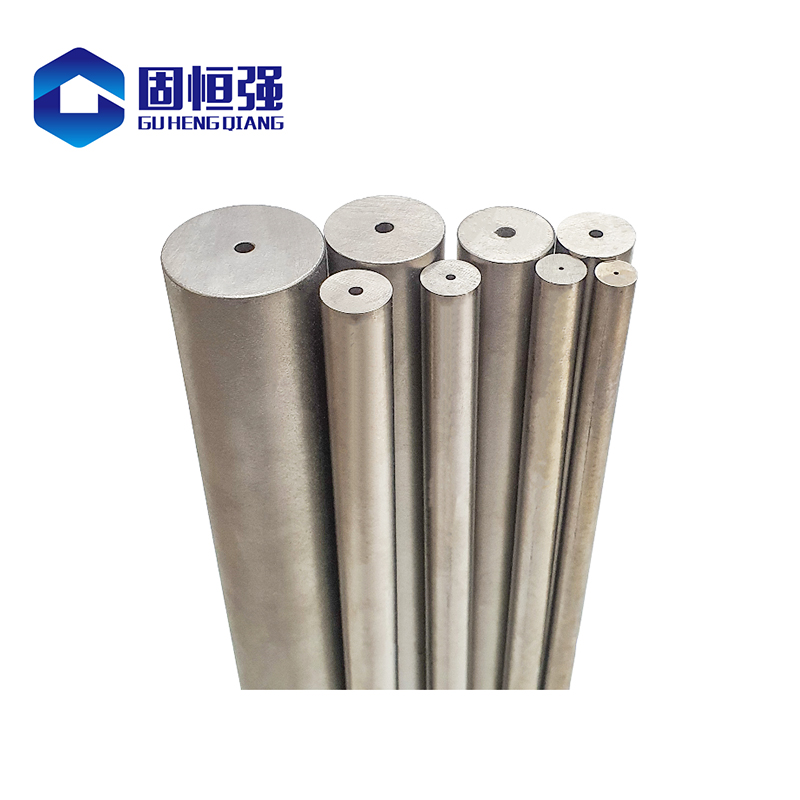

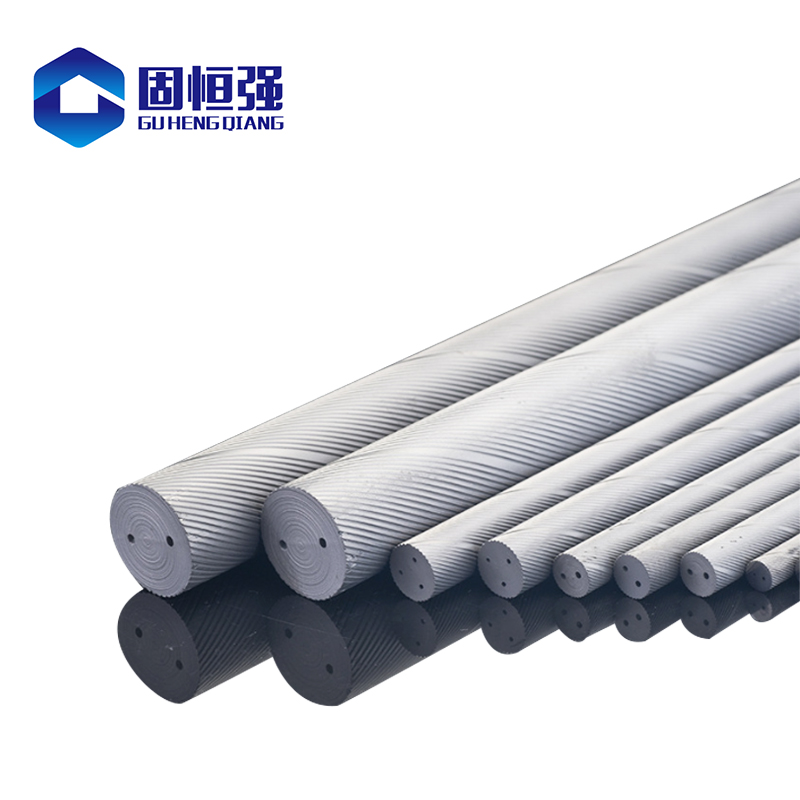

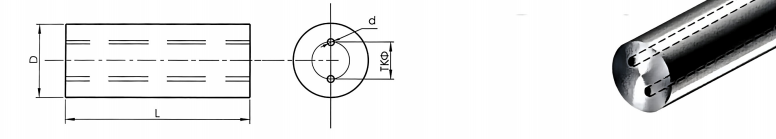

Round Cemented Carbide Rods with Central Coolant Hole

Product Description

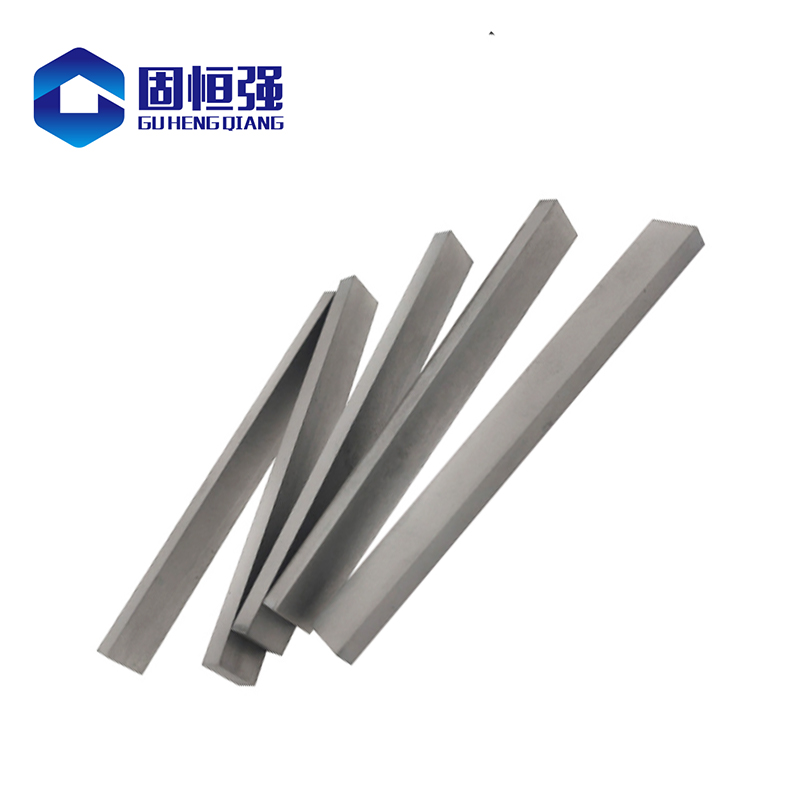

Cemented carbide round rod is tungsten steel round rod, also called tungsten steel rod. Cemented steel rods are moulded and extruded, and then formed by low pressure sintering, with stable quality, good bending strength and wear resistance. We specialise in cemented carbide round rods, have an excellent line of coolant and tungsten carbide rods, and produce and stock unground and ground tungsten carbide rods for you.

Our products have the following characteristics High strength, high wear resistance, high precision, high temperature resistance and corrosion resistance.

Applications

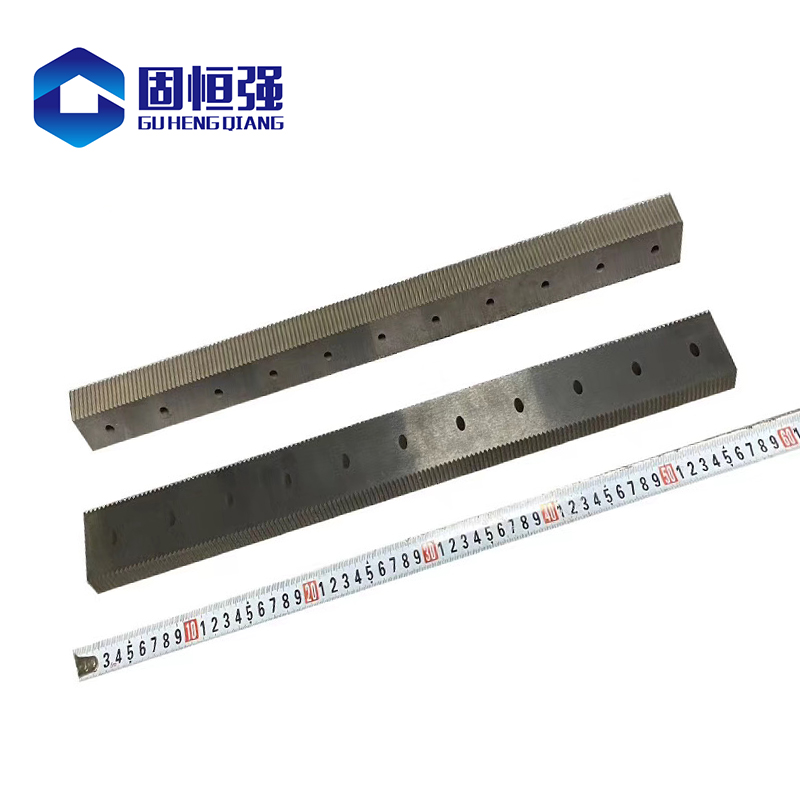

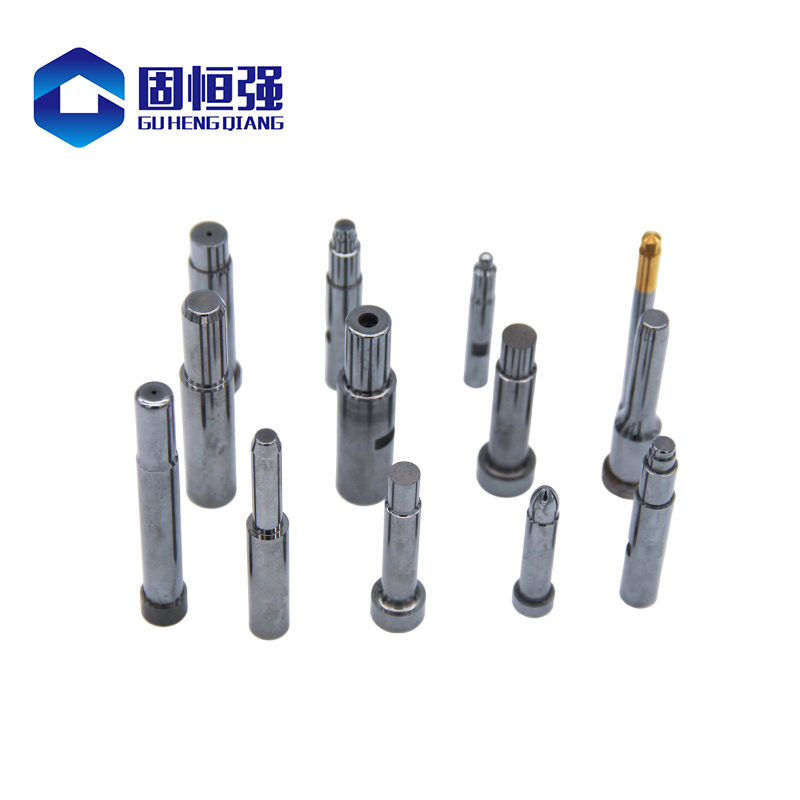

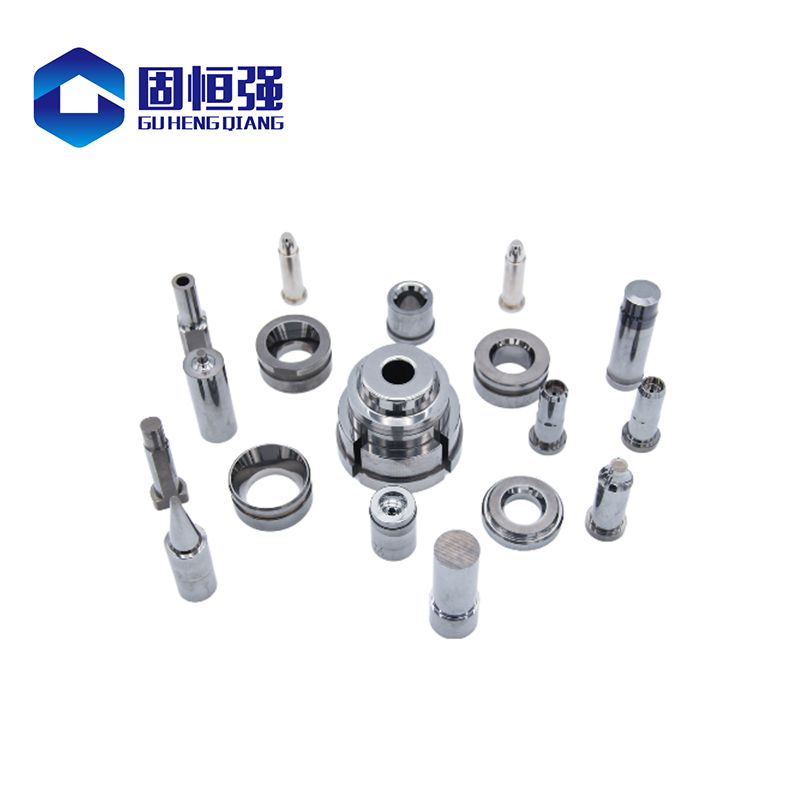

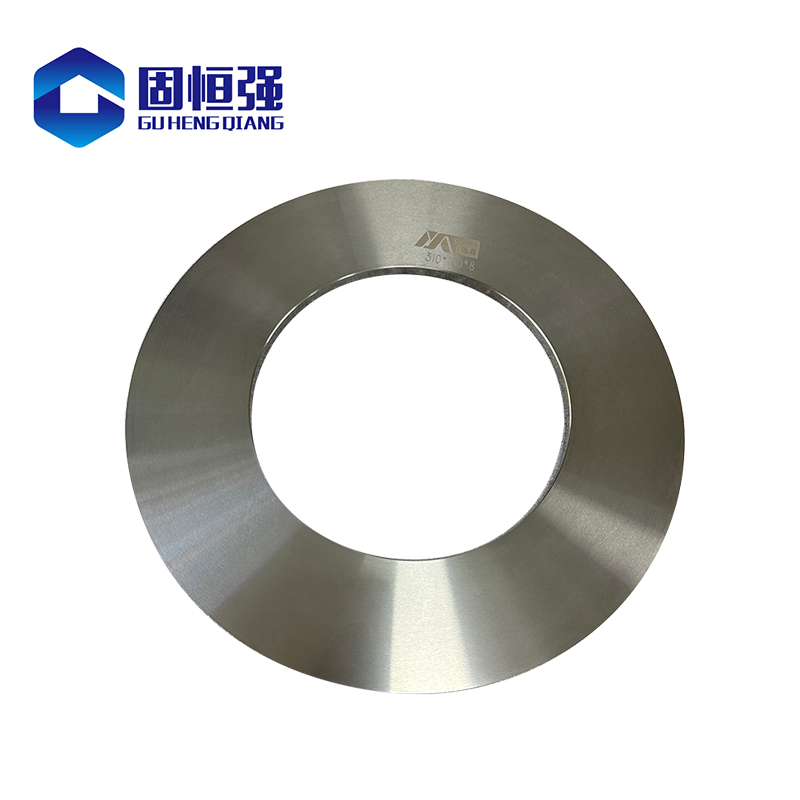

1.Mainly used in the field of cutting tools and mould stamping (solid carbide milling cutters, drills, reamers, PCB cutters and pins, punches, tension rods, etc.) for cutting, drilling, stamping and measuring, etc.

2.Used for processing wood and metal and other materials cutting

3.Widely used in many fields, such as machinery, chemical, petroleum, metallurgy, electronics and defence industries.

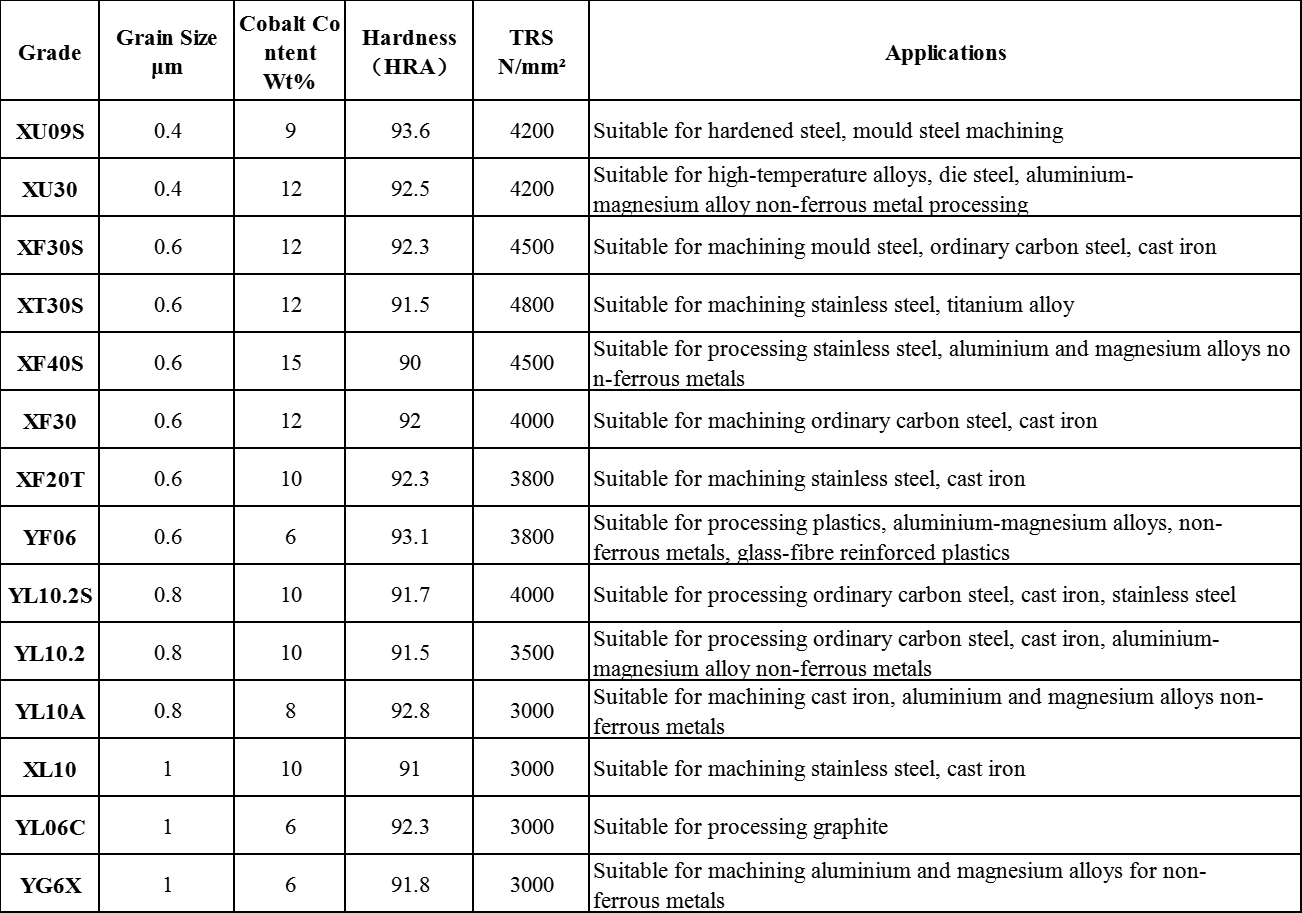

Grades of Cemented Carbide Rods

Cemented Carbide Rods Customisation

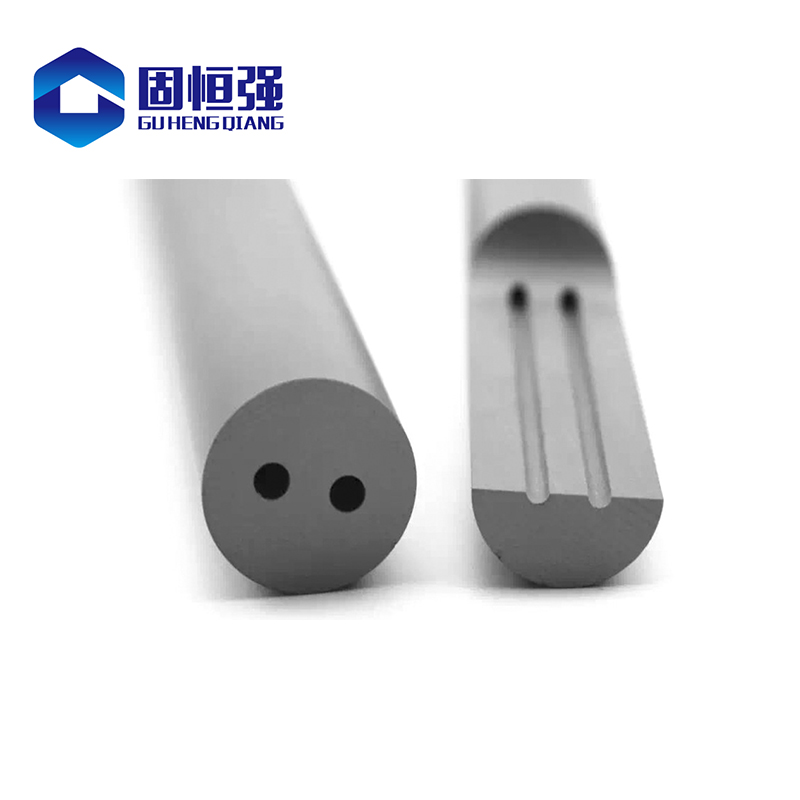

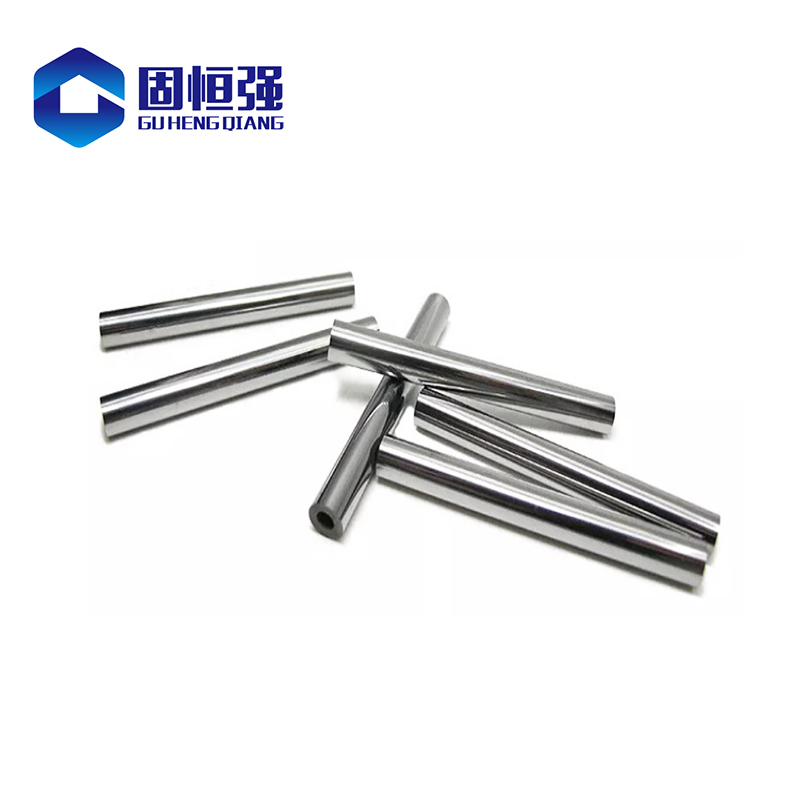

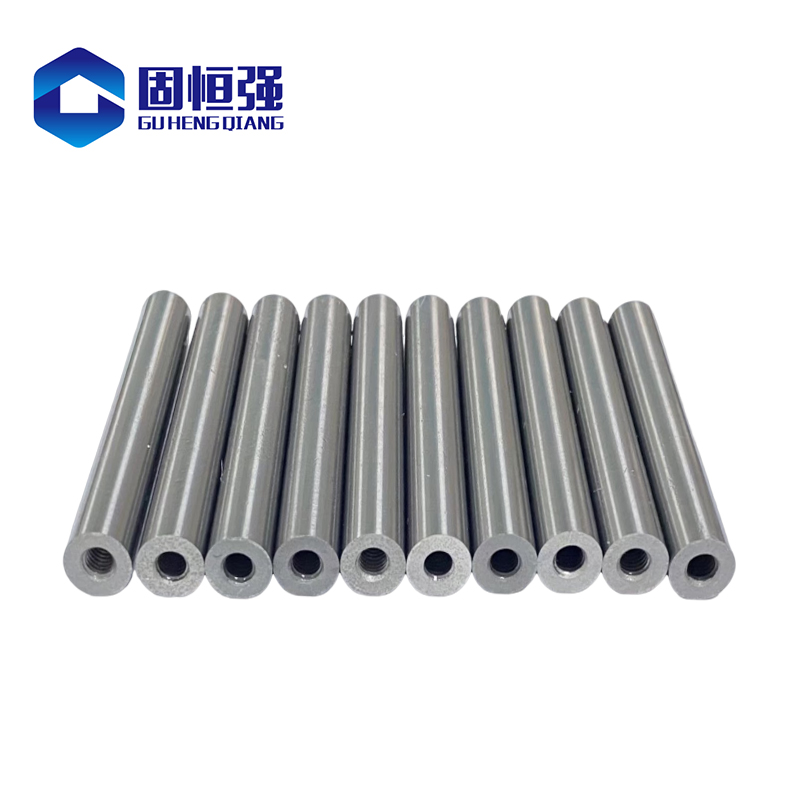

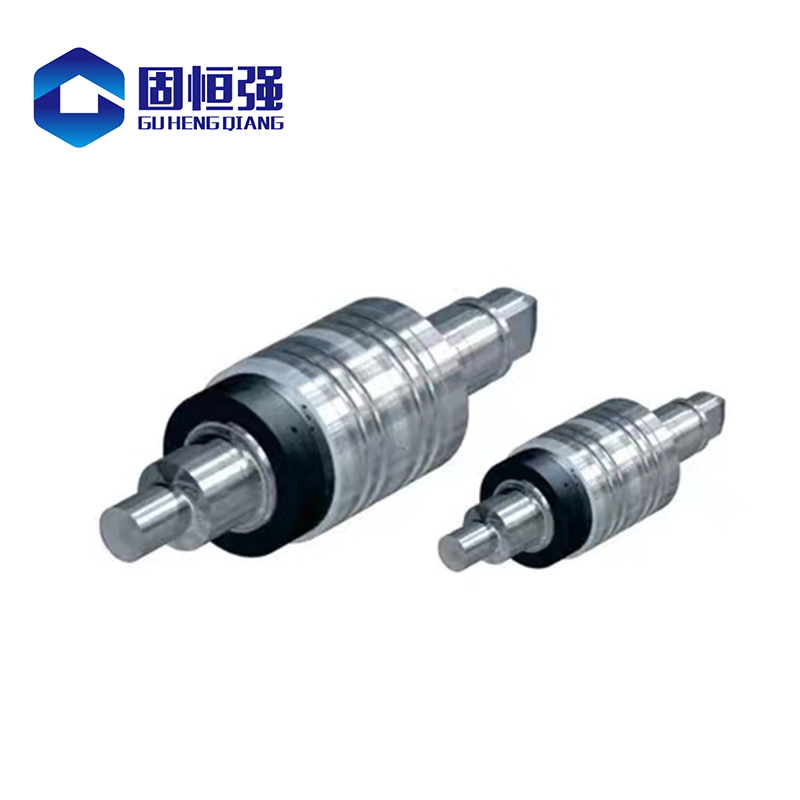

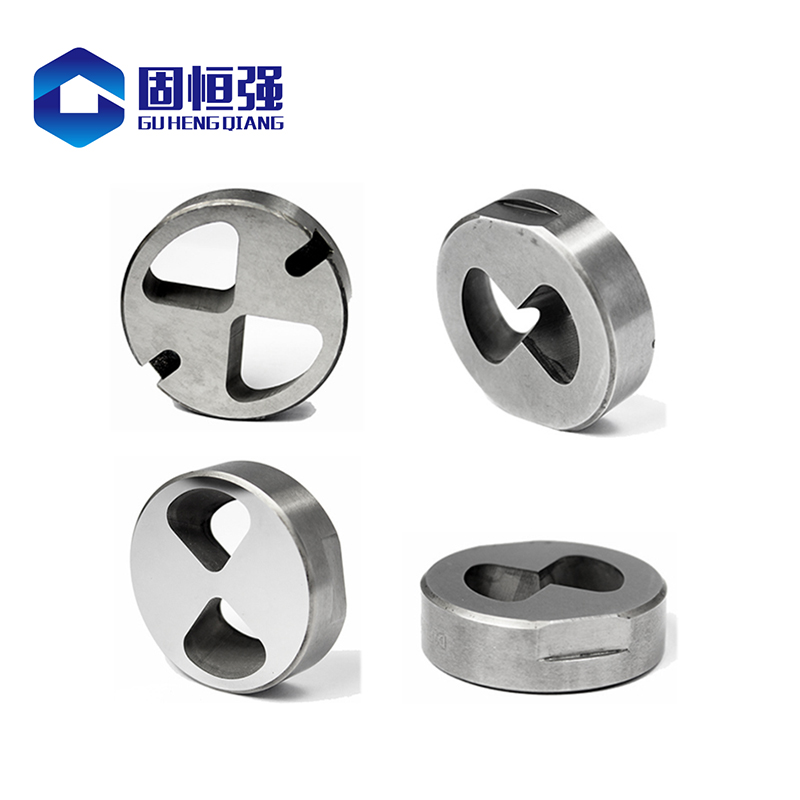

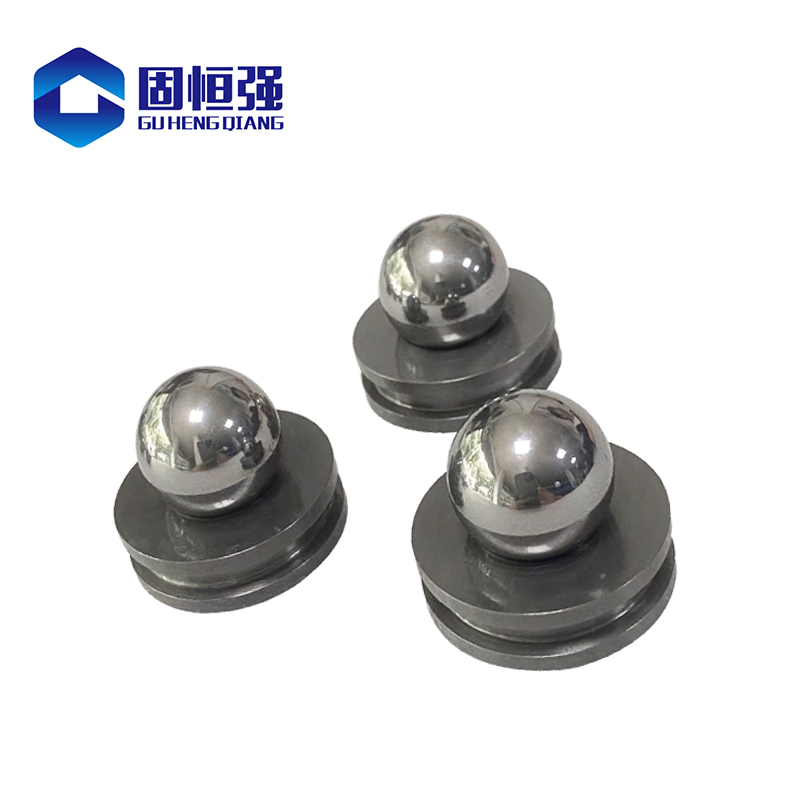

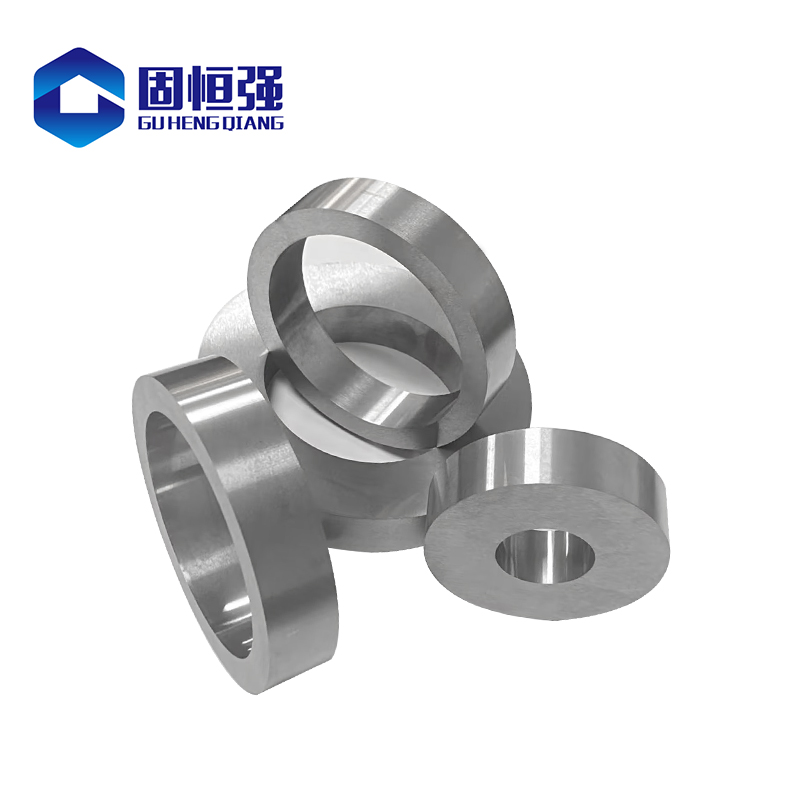

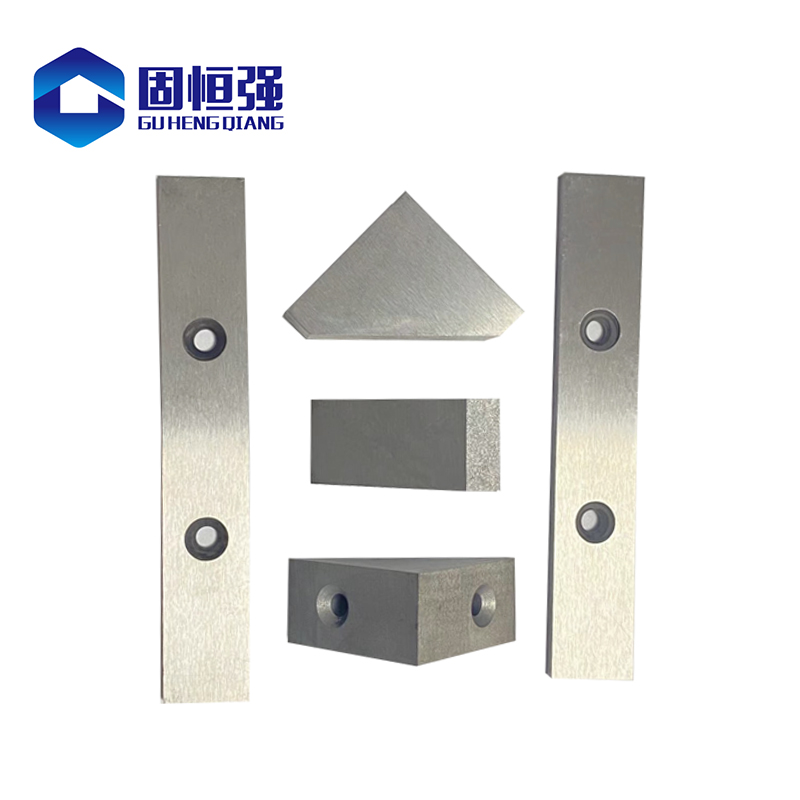

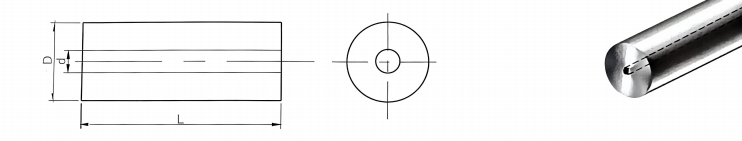

1.All types of round rods can be produced, blank rods, fine grinding rods, single hole, double hole, multi-hole, internal and external spiral rods, etc.

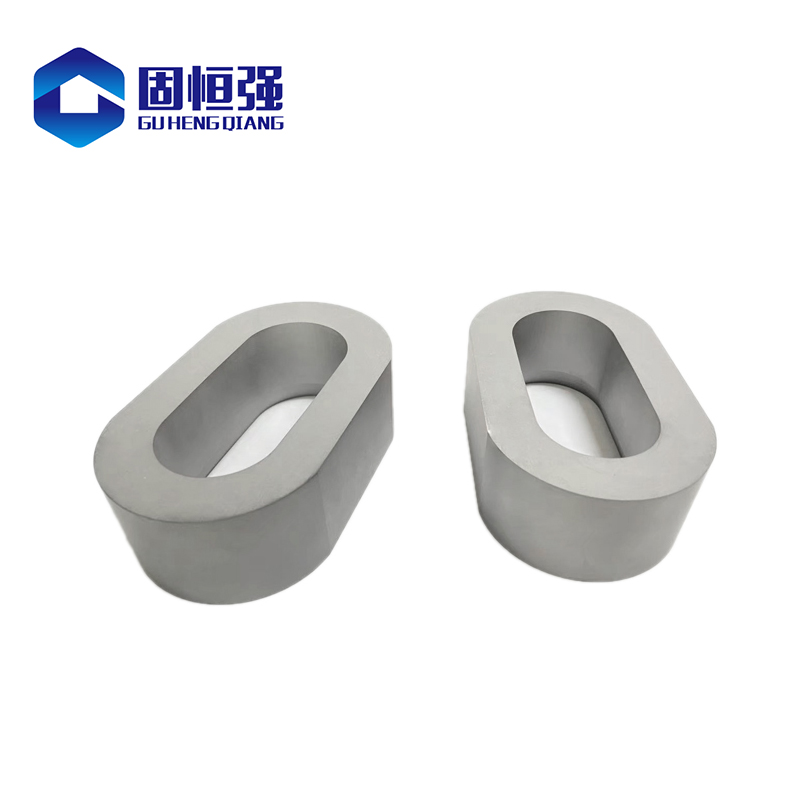

2.Mirror polishing, flattening, chamfering, wire cutting, grinding sharp corners, multiple steps, etc.

3.We can customise according to your requirements, and can recommend our suitable grades according to your working conditions and processed materials.

4.We can process all kinds of shaped parts, non-standard tools, etc.

5.We can customise various types of non-standard tools according to your drawings and samples.

Reference Drawings

FAQ

Q1. Are you a manufacturer?

A: Yes, we are. We have the best factory to produce for you,could guarantee the price is the most competitive.

Q2. What is your terms of payment?

A: T/T 50% as deposit, and 50% balance before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. How about your delivery time?

A: Lead time as fast as 7-15 days!

Q4. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.Our production is based on ISO9001,we have more than 10 years experience of QC team and strictly quality control system in our production process.

Q6. What about the package?

A.It can make as the you need and depend on the products shapes. Generally, we can provide iron drum, carton, wooden case, and bag packages.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.