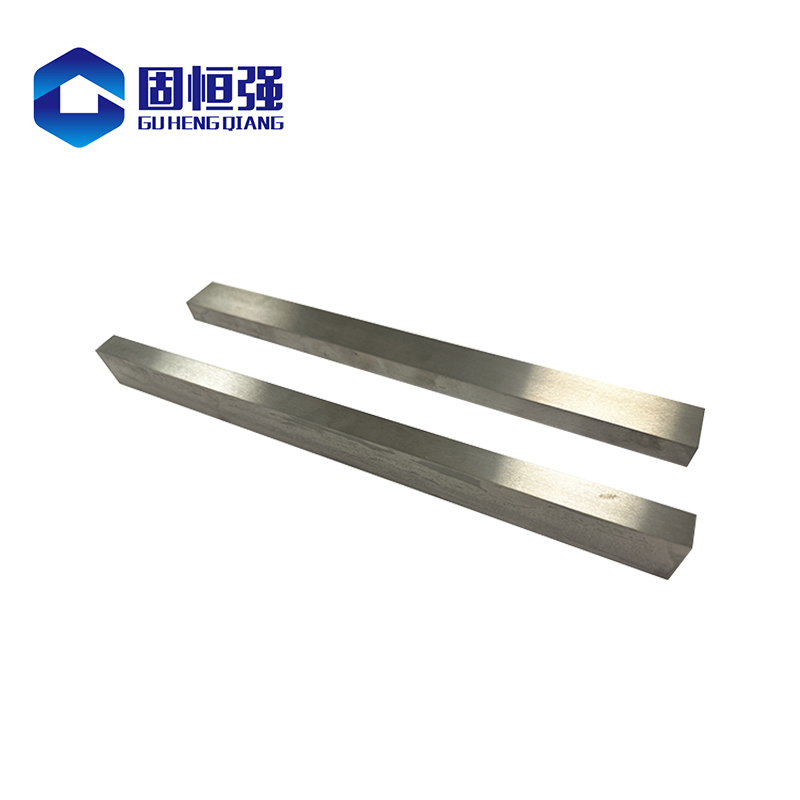

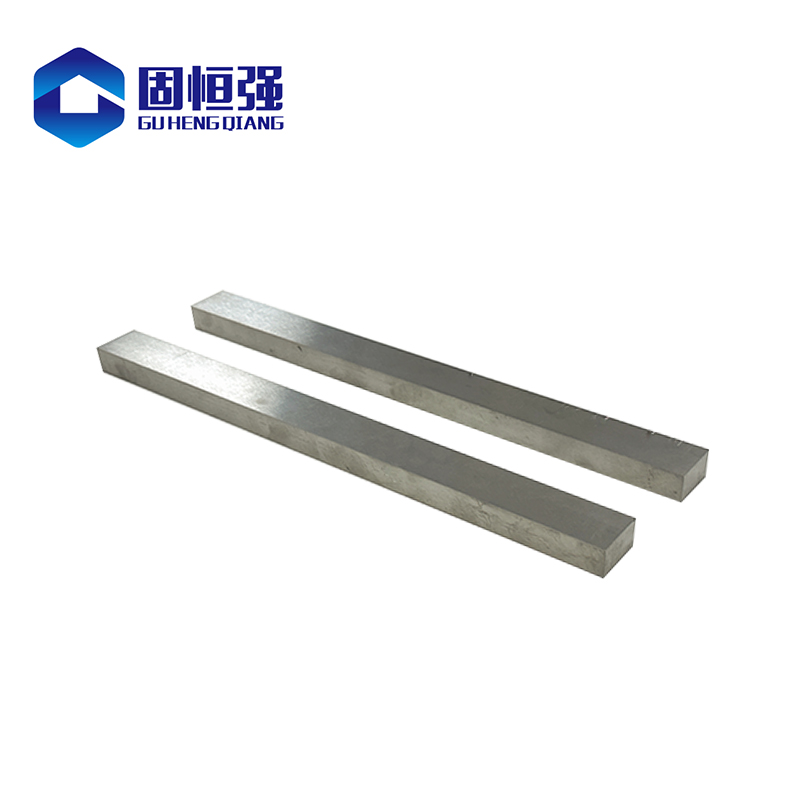

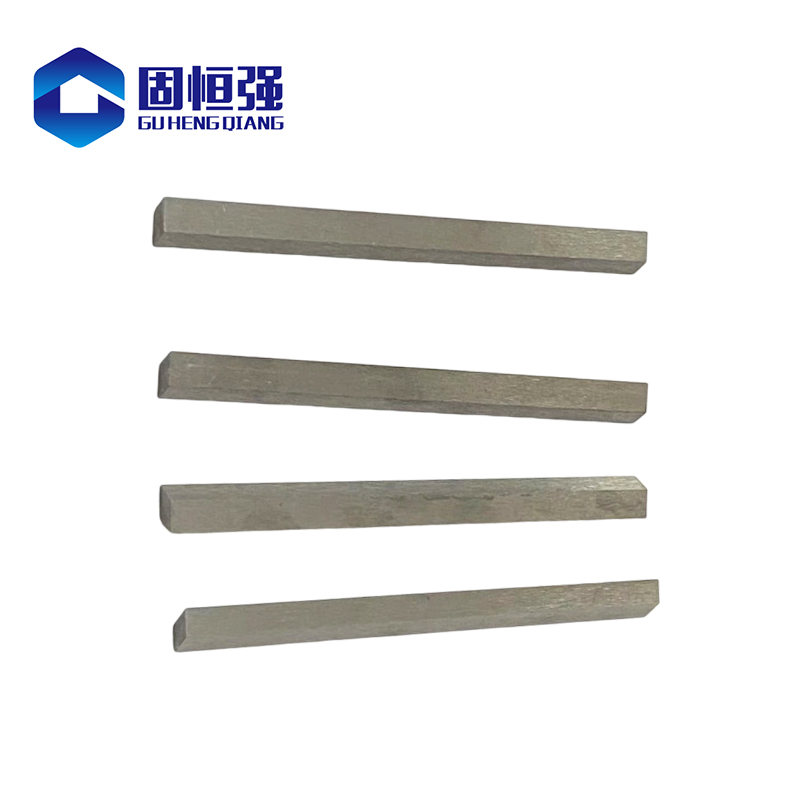

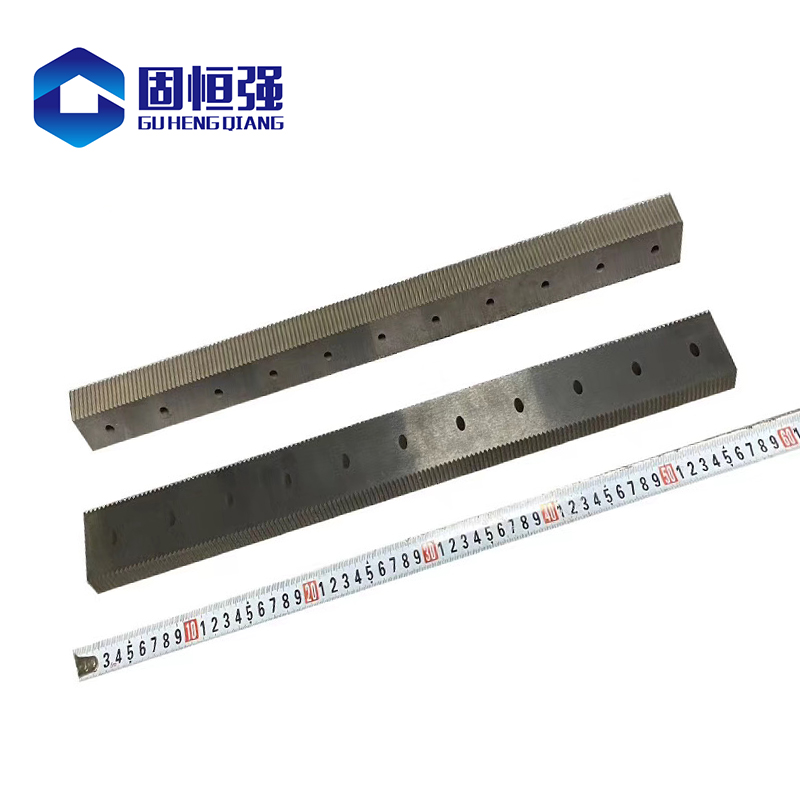

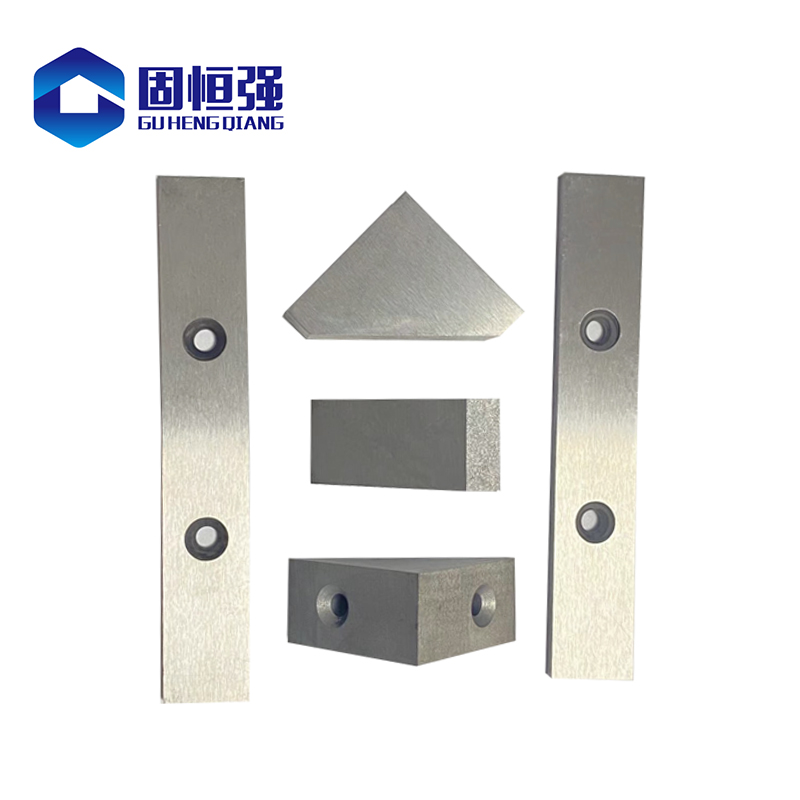

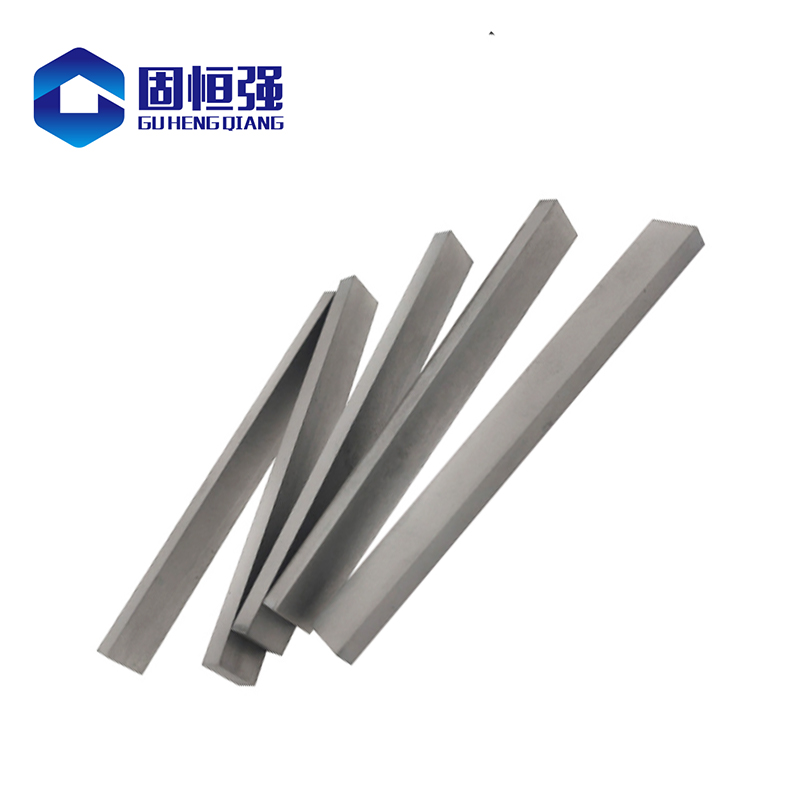

Customized Tungsten Carbide Non-magnetic Blank Carbide Strip for Wood Cutting

Product Description

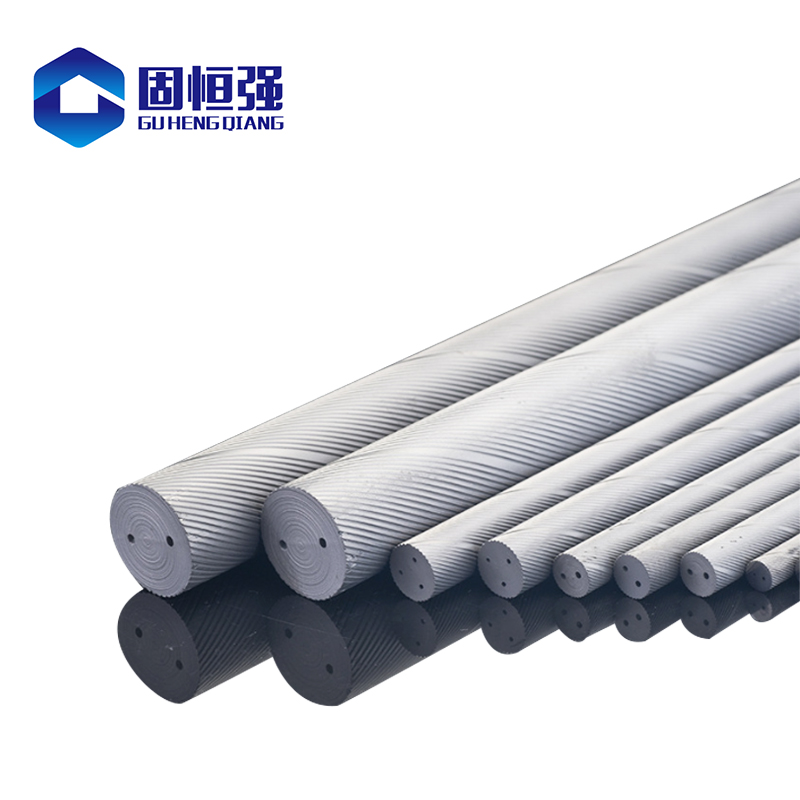

Cemented Carbide non-magnetic strip is sintered by moulding and extruding in two ways, which has the characteristics of high wear resistance and high hardness, and the products have been tested by non-destructive ultrasonic flaw detection without sand holes and air holes, with high denseness, high hardness and impact resistance, and long service life.

Our company’s carbide plate, long strip with a variety of complete specifications. Welcome to consult and order!

Cemented carbide non-magnetic strip has excellent hardness, high hardness, good wear resistance, high modulus of elasticity, high compressive strength, good chemical stability (acid, alkali, high temperature oxidation resistance), low impact toughness, low coefficient of expansion, thermal conductivity, electrical conductivity and iron and its alloys are similar to the characteristics.

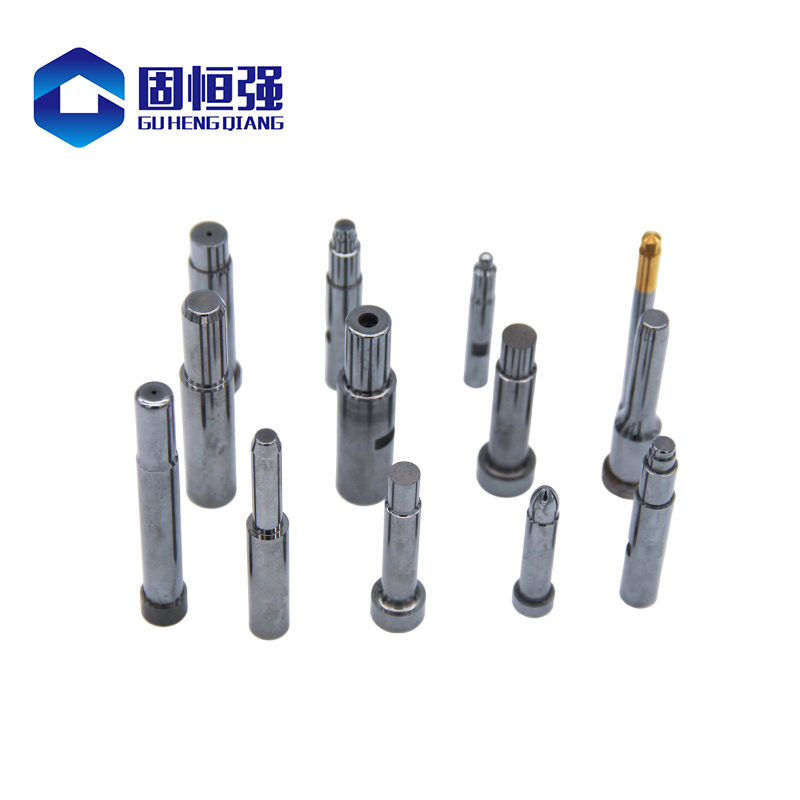

Applications

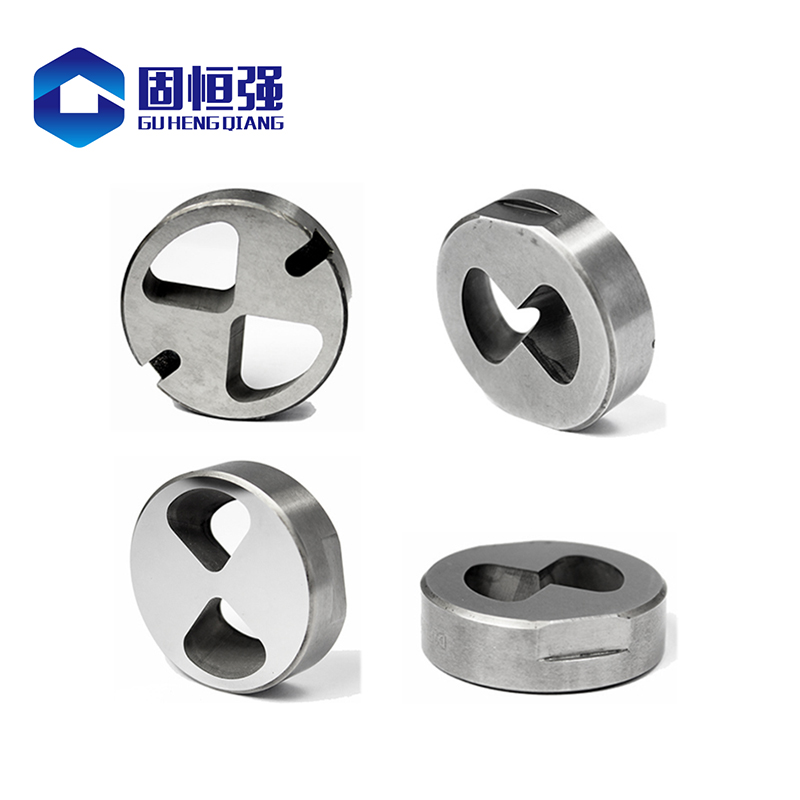

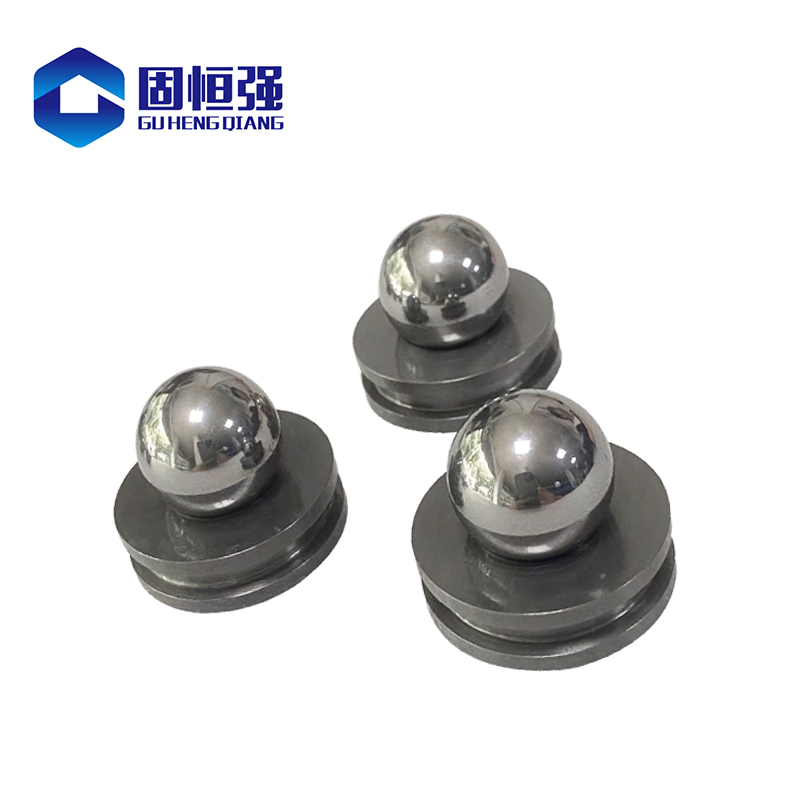

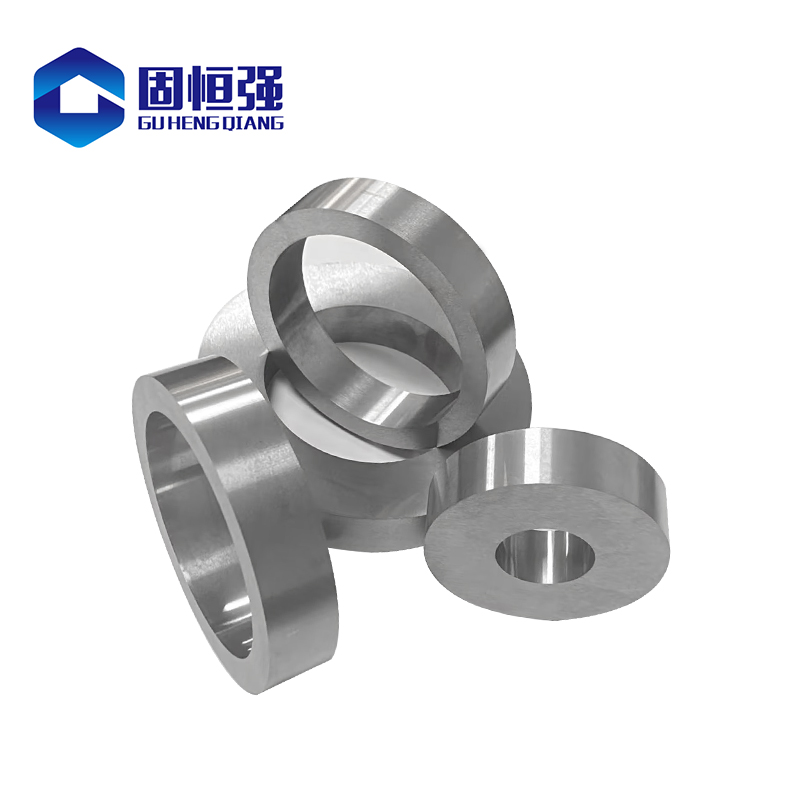

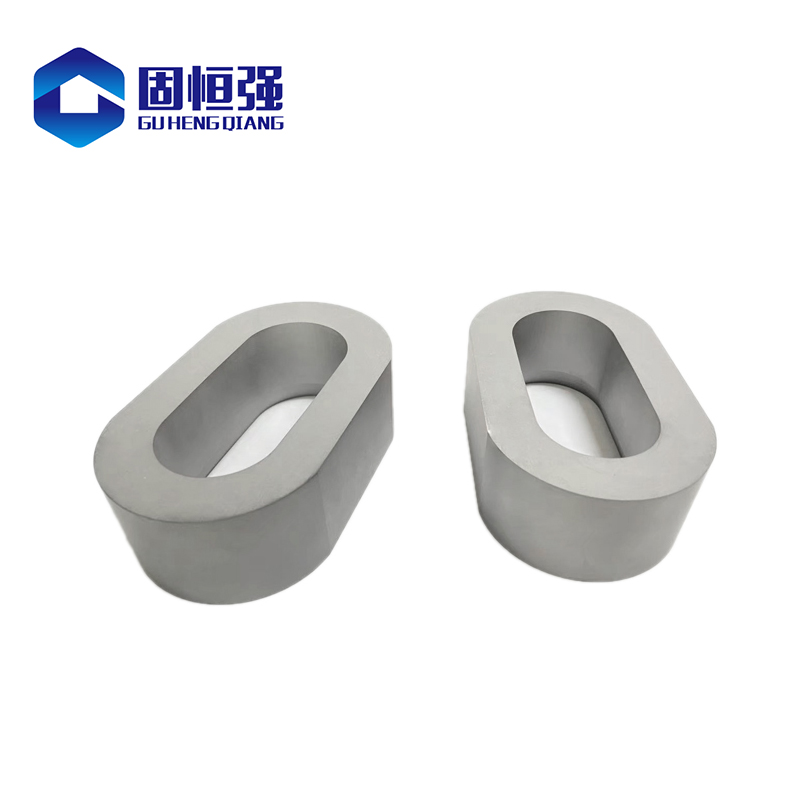

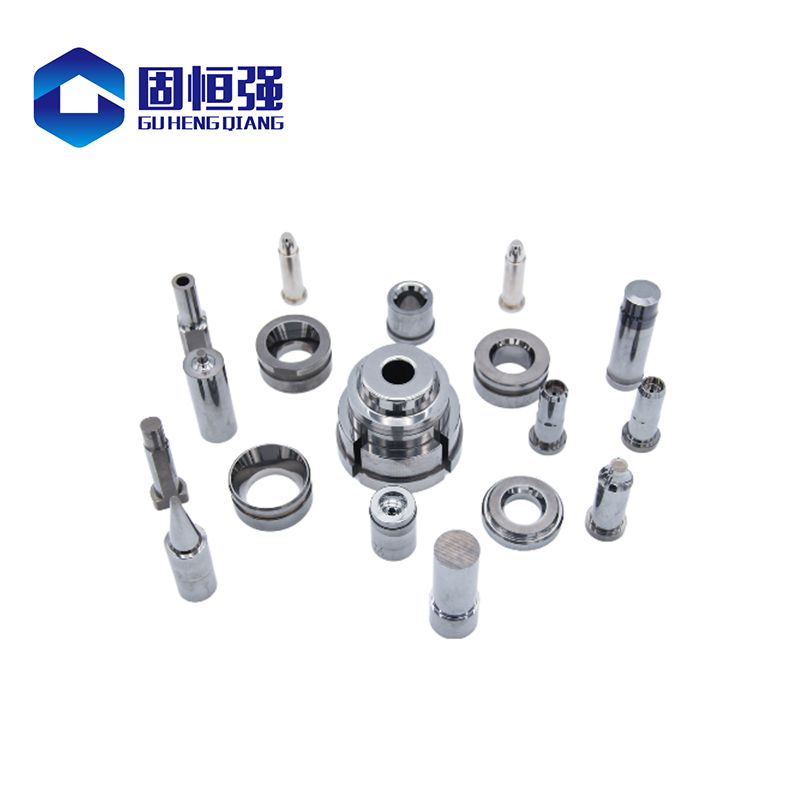

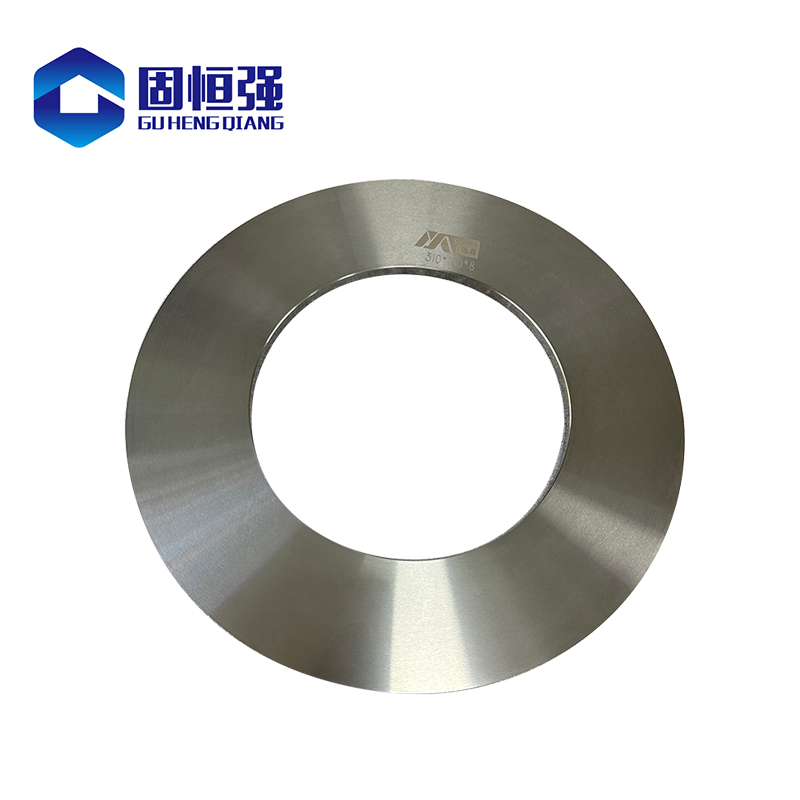

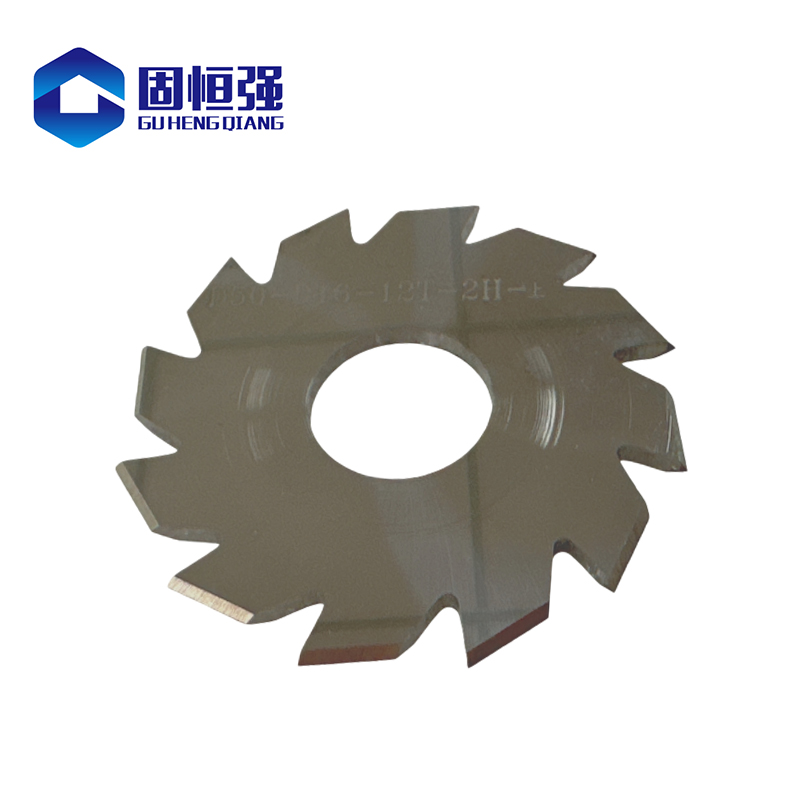

1.magnetic material moulds, stamping moulds, drawing moulds, powder metallurgy moulds, refractory moulds, ceramic moulds, etc.

2.construction materials, mining equipment, etc.

3.Custom-made non-standard non-magnetic strips according to your drawings and samples.

4.according to your use and working conditions to recommend our different grades of materials, but also according to your working conditions to provide the design of our products.

Grades of Cemented Carbide Non-magnetic Strip

| Grade | Nickel

Content |

Density (g/cm³) |

Hardness (HRA) |

TRS

(MPA) |

Grain Size (μm) |

| YN6S | 6.0 | 14.82 | 92.0 | 2150 | 0.8 |

| YN8S | 8.0 | 14.80 | 91.5 | 2200 | 0.8 |

| YN10S | 10.0 | 14.60 | 90.5 | 2350 | 0.8 |

| YN14S | 14.0 | 14.15 | 88.8 | 2300 | 1.0 |

| YN20S | 20.0 | 14.10 | 88.5 | 2400 | 0.8 |

| YNS-10 | 10.0 | 14.65 | 92.0 | 2500 | 0.6 |

| YNS-8 | 10.0 | 14.80 | 92.4 | 2200 | 0.6 |

Cemented Carbide Non-magnetic Strip Specifications

Note:Customization is accepted. |

||||||||||||||||||||||||||

Attentions

1.Common Sense

Because the non-magnetic carbide is extremely hard and brittle, it is easy to break when impacted by external force. It is forbidden to knock or throw the alloy material when installing and use the non-magnetic alloy material; please pay attention to safety during operation to avoid hurting your hands and feet.

Non-magnetic carbide may be damaged during processing. Therefore, please be sure to install safety settings and safety shields on the mechanical equipment.

2.Welding Processing

The non-magnetic alloy may crack during welding. Please confirm whether there is any cracking after welding and conduct heat preservation treatment on the product.

After heating in the atmosphere, the non-magnetic alloy will generally not be oxidized below about 900degrees (a color change is normal).

FAQ

Q1. Are you a manufacturer?

A: Yes, we are. We have the best factory to produce for you,could guarantee the price is the most competitive.

Q2. What is your terms of payment?

A: T/T 50% as deposit, and 50% balance before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. How about your delivery time?

A: Lead time as fast as 7-15 days!

Q4. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.Our production is based on ISO9001,we have more than 10 years experience of QC team and strictly quality control system in our production process.

Q6. What about the package?

A.It can make as the you need and depend on the products shapes. Generally, we can provide iron drum, carton, wooden case, and bag packages.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.