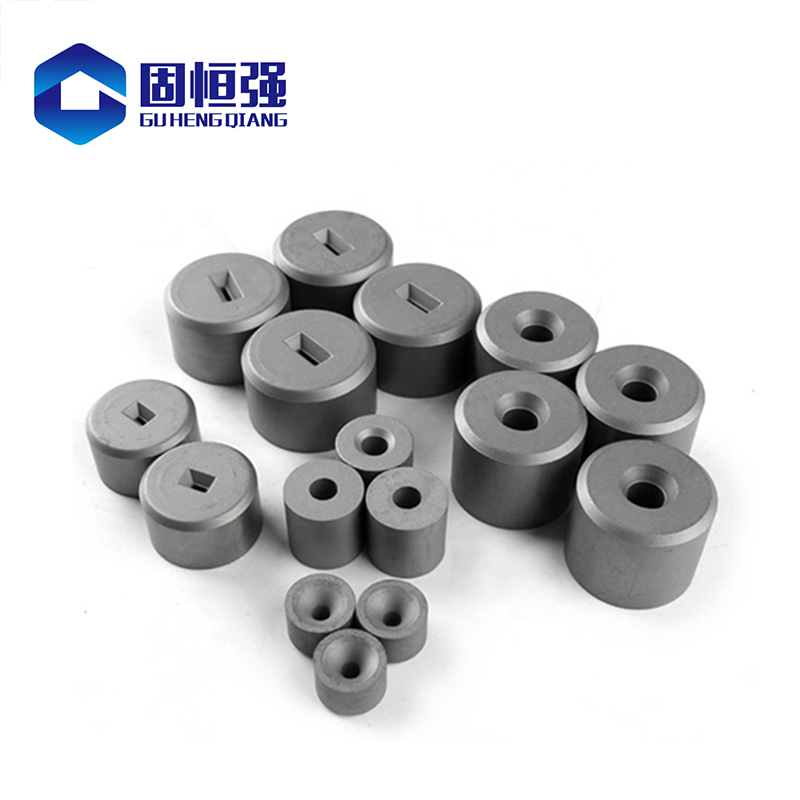

Cemented Carbide Drawing Dies

Introduction of Cemented Carbide Drawing Dies

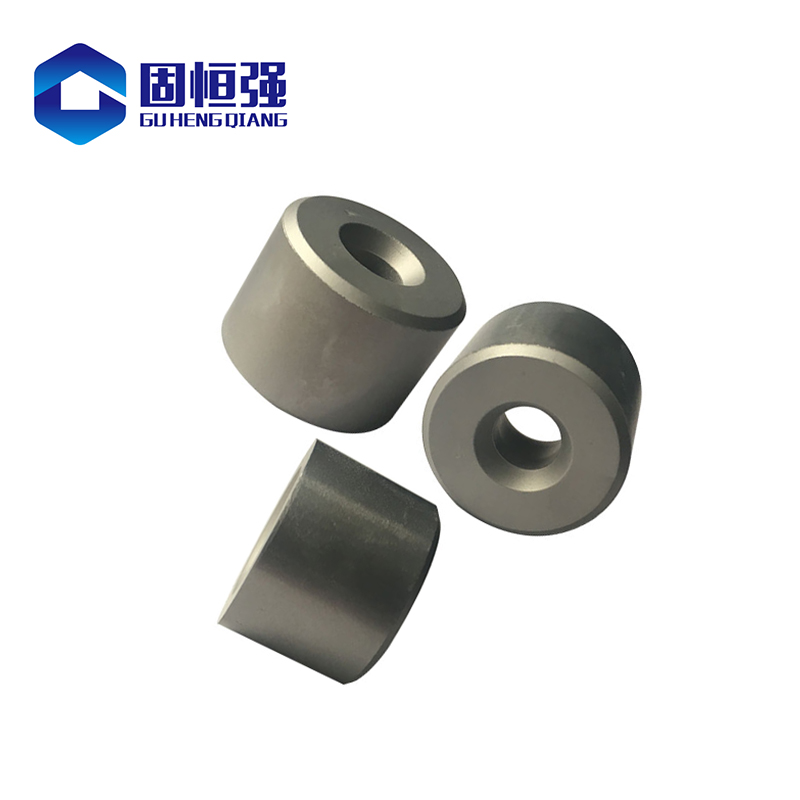

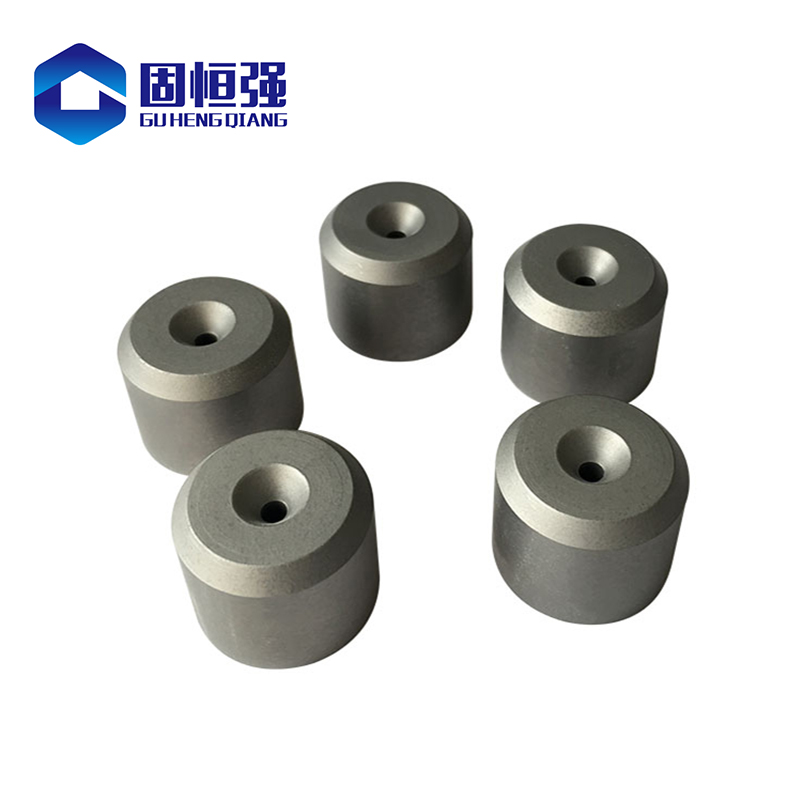

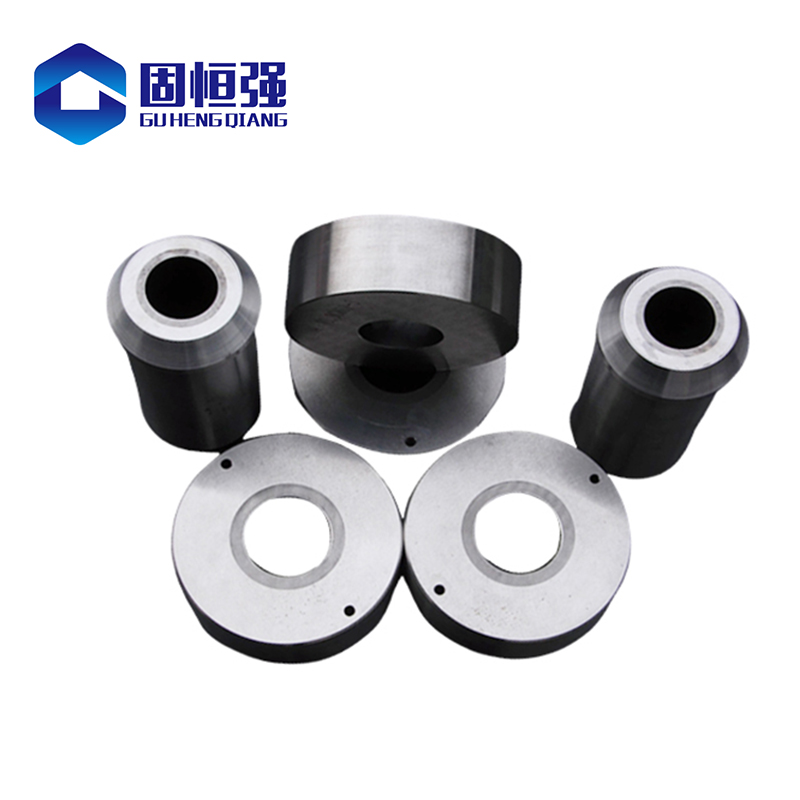

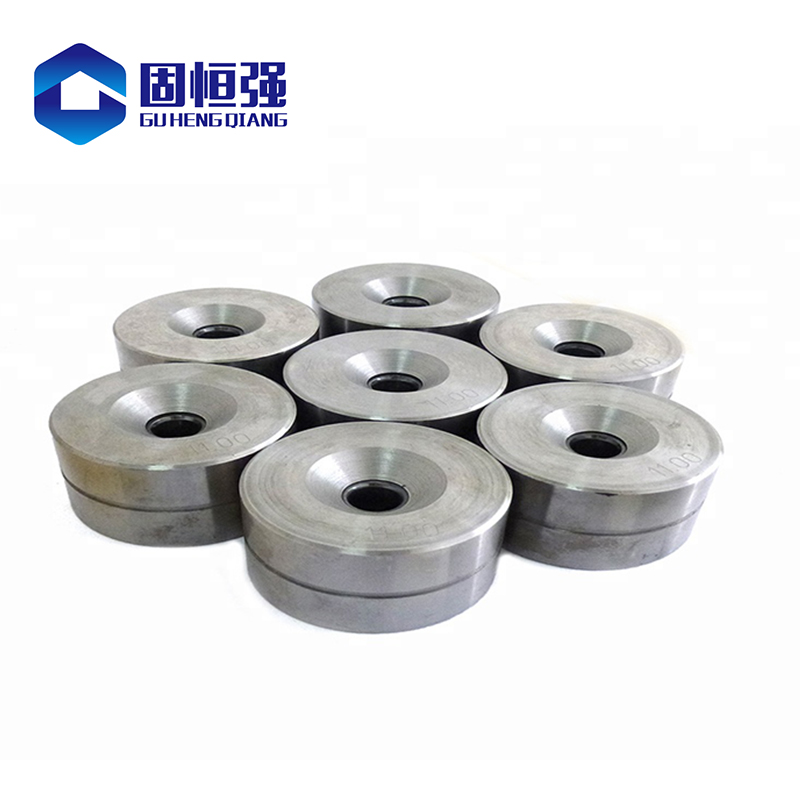

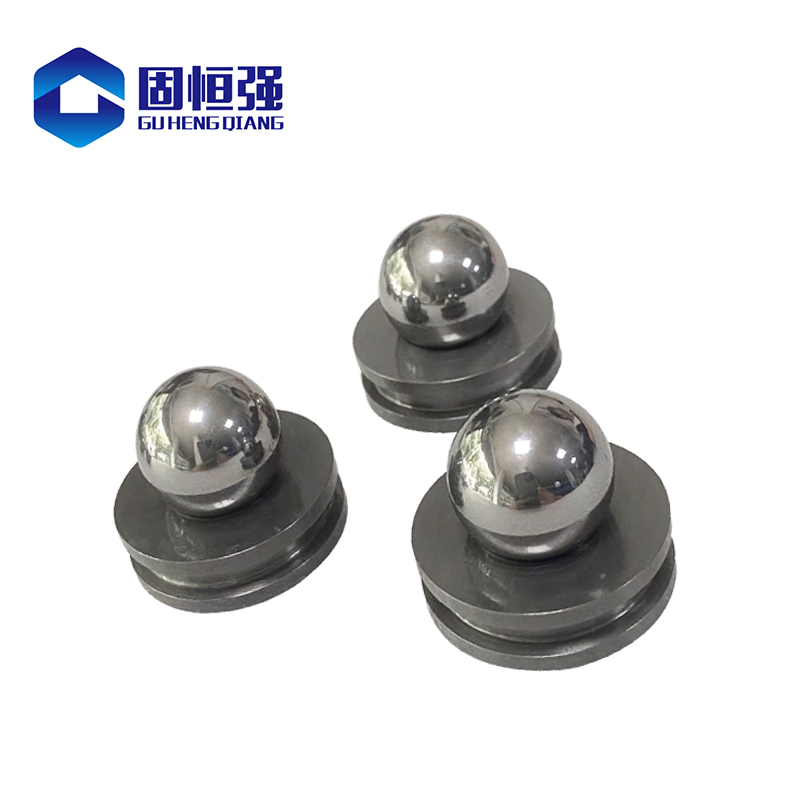

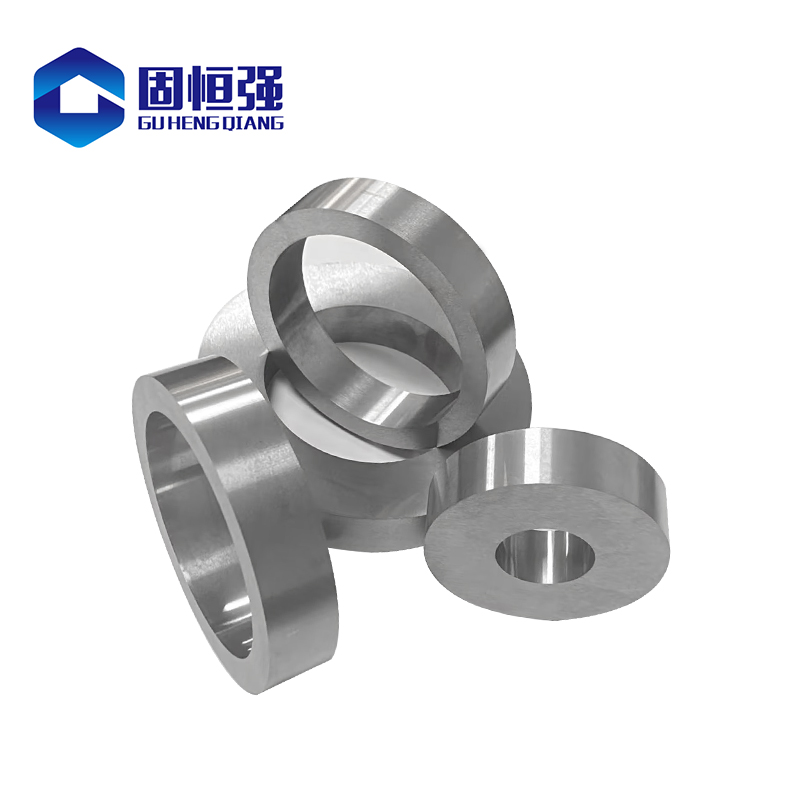

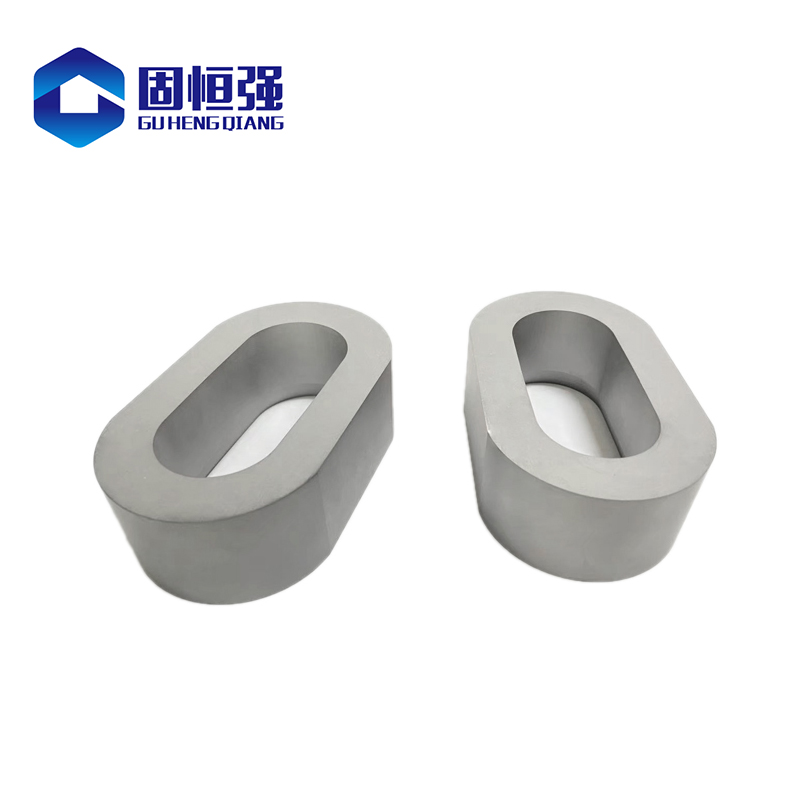

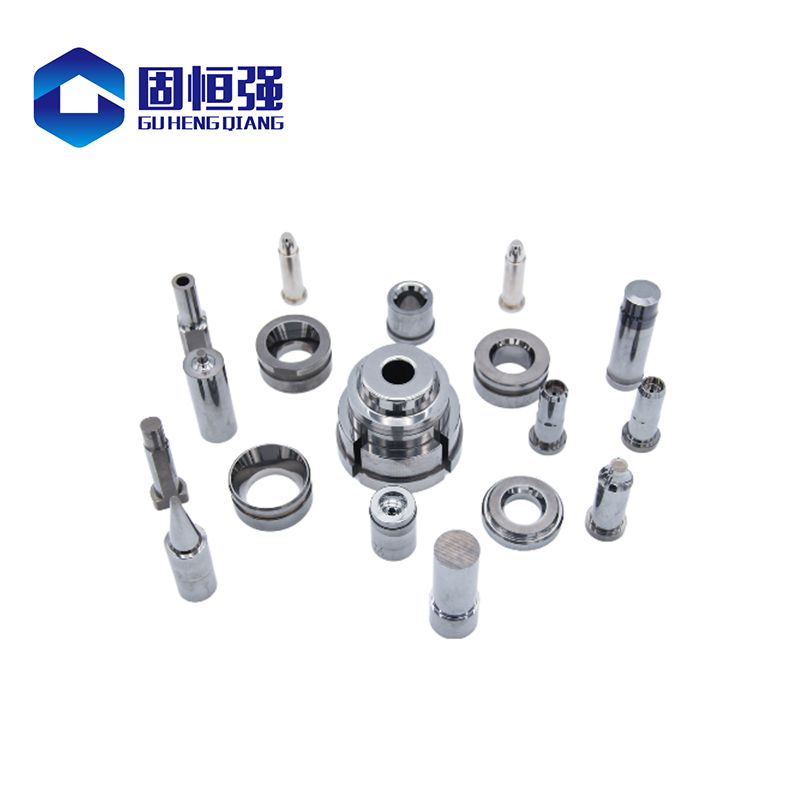

Cemented carbide drawing dies, bright surface, wear resistance exceeds mold steel, does not strain the surface of the processed parts. Compared with the steel mold, the advantage is good heat conductivity, non-stick mold, can ensure the work of the mold temperature distribution is uniform, will not be due to the local high temperature so that the mold cracks, will not make the stretched products appear cold sweat, stripping marks, wrinkles phenomenon, and significantly improve the surface quality of the product (especially in the stainless steel products, deep drawing when the effect of the performance is outstanding).

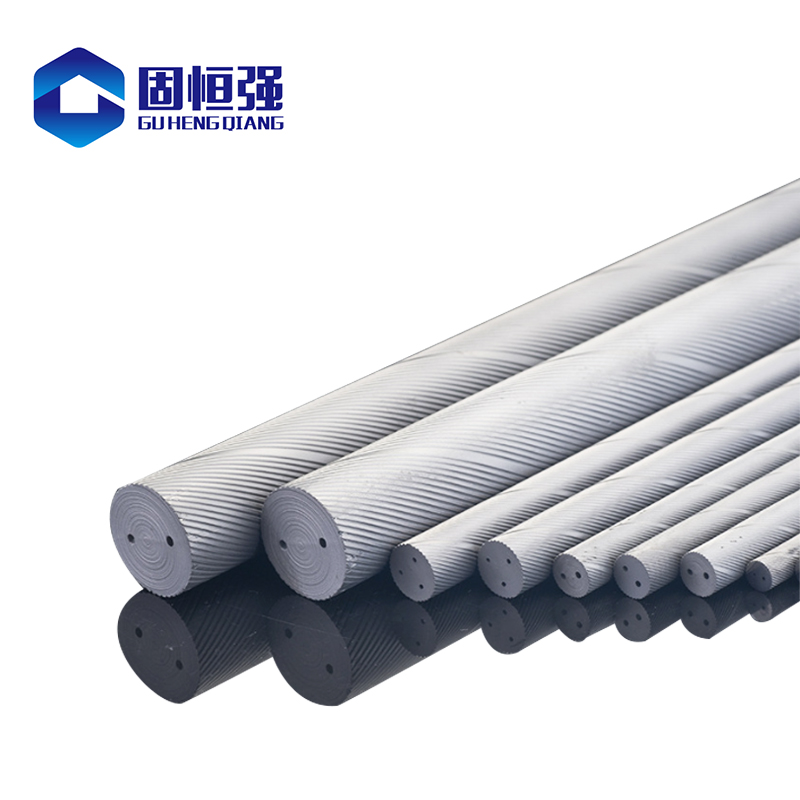

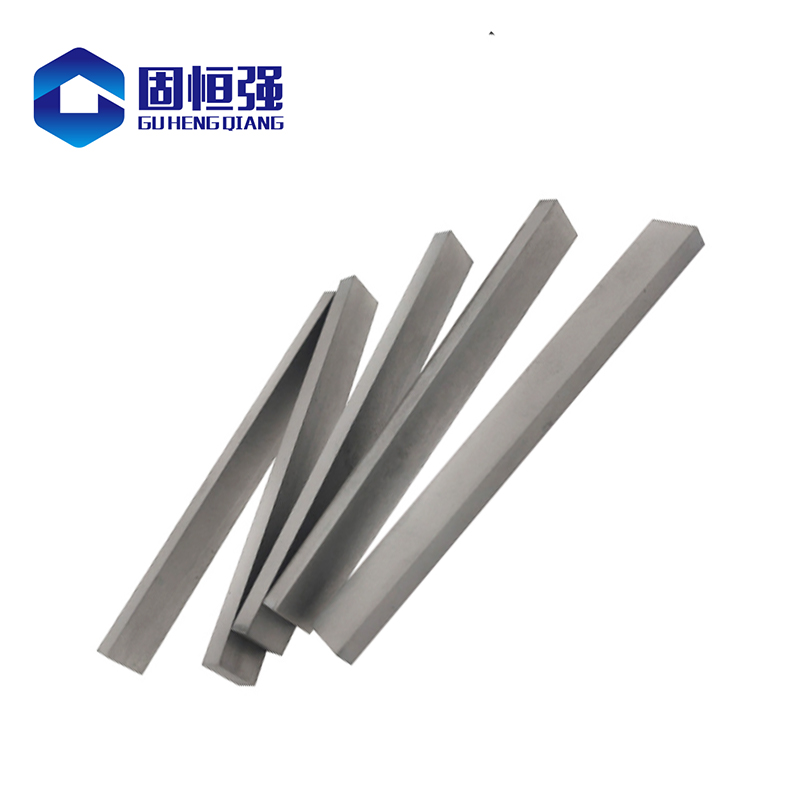

Processing technology: the use of cemented carbide raw material production, overpressure sintering into blanks and then grinding, polishing, grooving, punching, coating or tapping. The toughness will be better than conventional production, and the service life is also increased by 3-5 times.

Application Areas of Carbide Drawing Mold

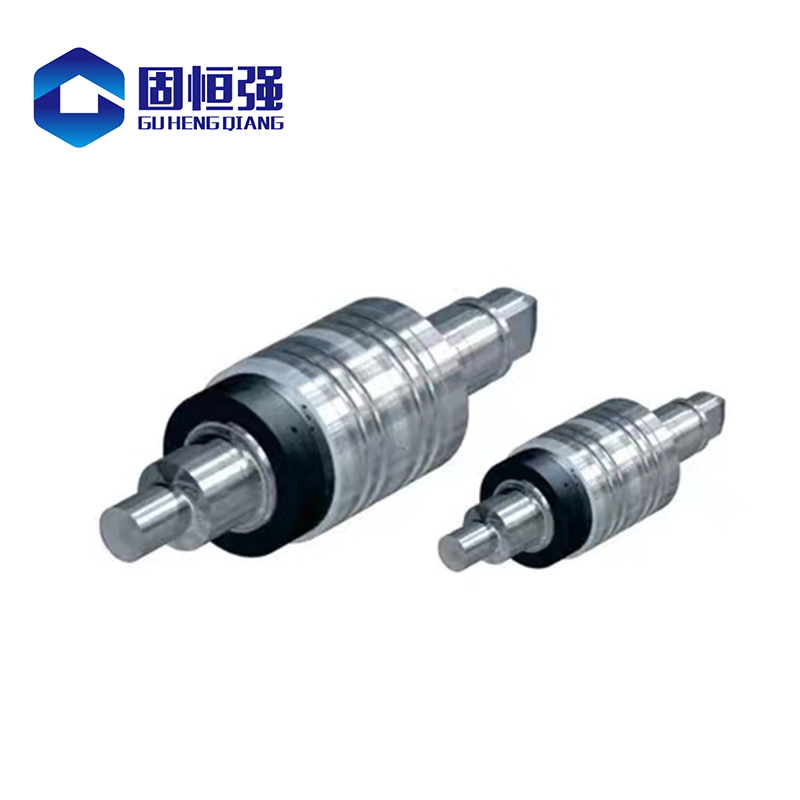

1. Widely used in petroleum transmission pipe, gas tank pipe, oversized gas cylinder steel pipe, pressure vessel dish pipe and other industries;

2. Widely used in various industries such as stainless steel cutlery, utensils, hardware fittings, stretching, forming, etc., as well as non-magnetic molds for magnetic industry;

3. Suitable for wet drawing of high carbon steel wire, steel cord, cutting steel wire, coated steel wire and welding wire;

4. Suitable for wet/dry drawing of high carbon steel, welding wire, dry drawing of non-ferrous metal materials, CVD substrate.

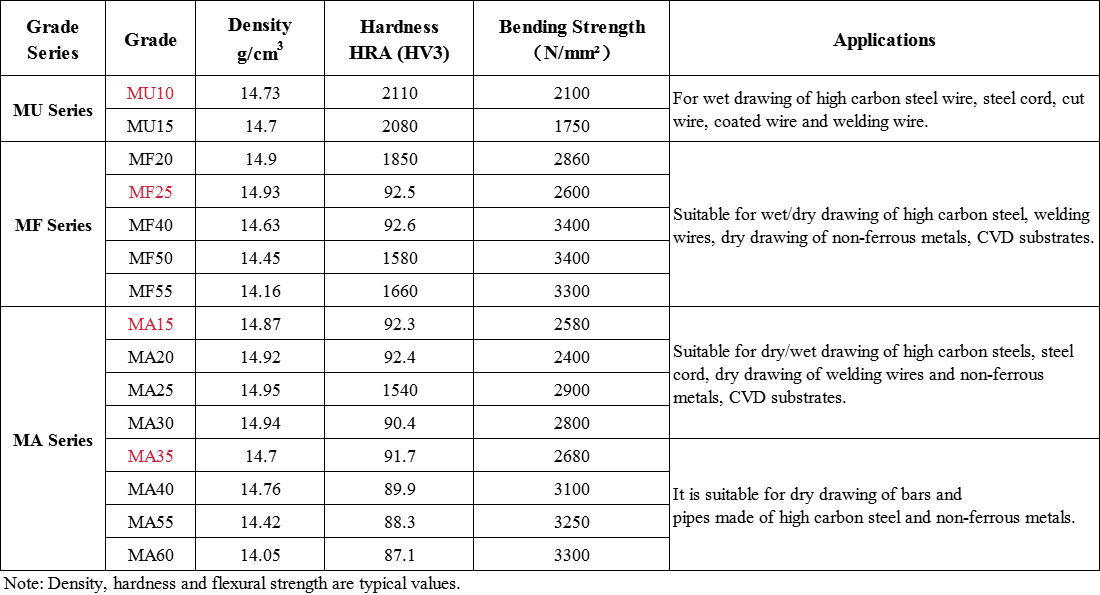

Introduction of Cemented Carbide Drawing Die Grades

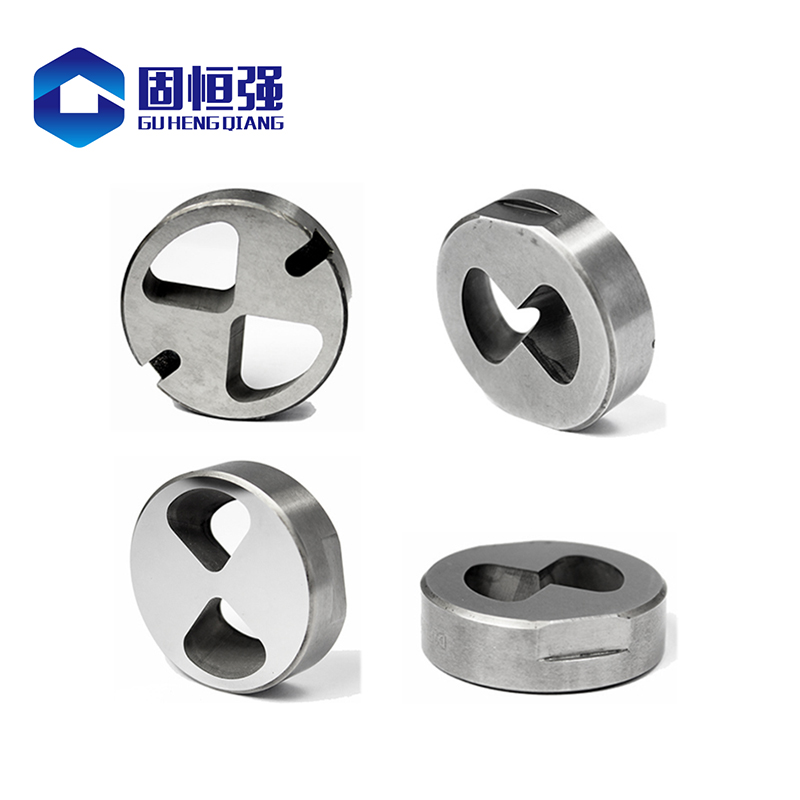

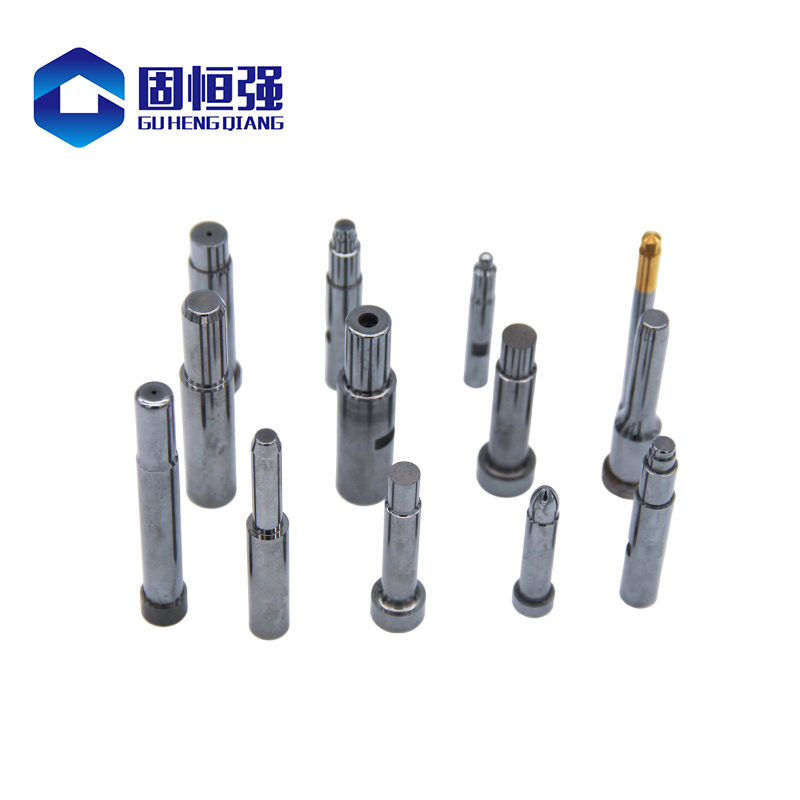

Cemented Carbide Drawing Die Model representation rules

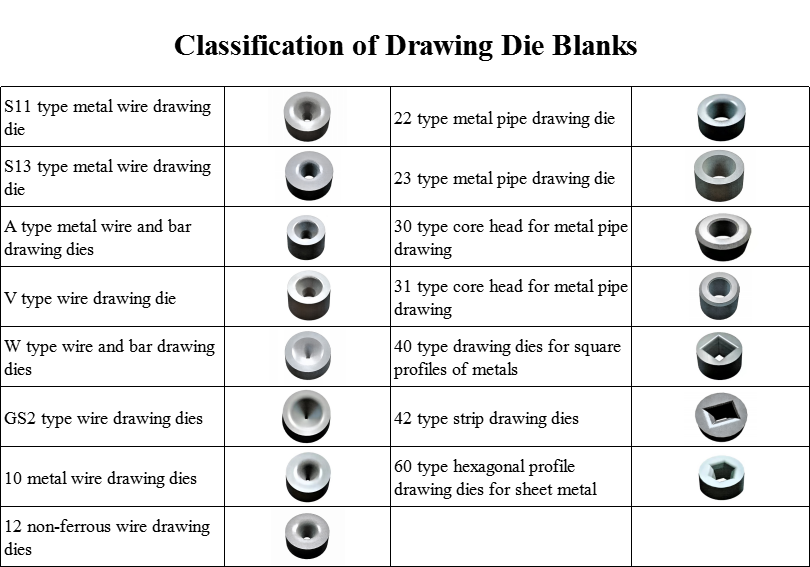

1.Classification of Drawing Die Blanks

2. Drawing die blank model representation rules

Drawing die blank model by the type category, outer diameter, height, compression angle, bore parameters, such as five code components.

Example: S11-008 06 12-1.2

① ② ③ ④ ⑤

① is the type code of drawing die blank.

② is the outer diameter of the drawing die blank code, with three digits, unit: mm; less than three, then add "0" to fill in the front.

③ for the drawing die blank height code, with two figures, unit: mm; less than two, then add "0" to fill in the front.

④ is the compression angle code of the drawing die blank, expressed in two digits, unit: °; if there is no compression angle, it is expressed in "00".

⑤ for the drawing die blank hole code:

Circular hole with inner diameter size d, unit: mm; when the inner diameter size is not greater than 1mm take two decimal, when the inner diameter size is greater than 1mm take a decimal;

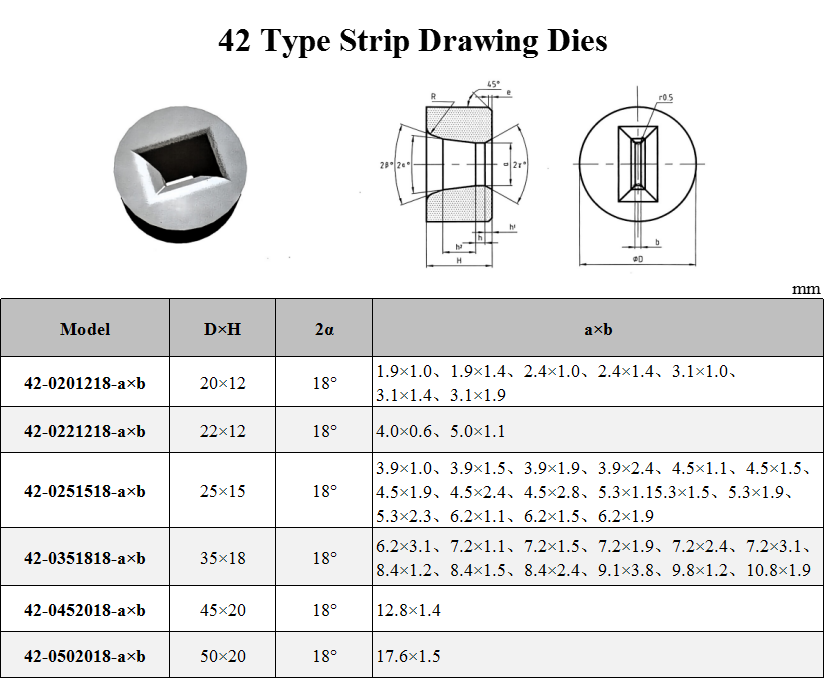

Quadrilateral bore is expressed by bore length a x bore width b in mm, taking one decimal place;

Hexagonal bore with internal tangent circle size s, unit: mm, take one decimal place.

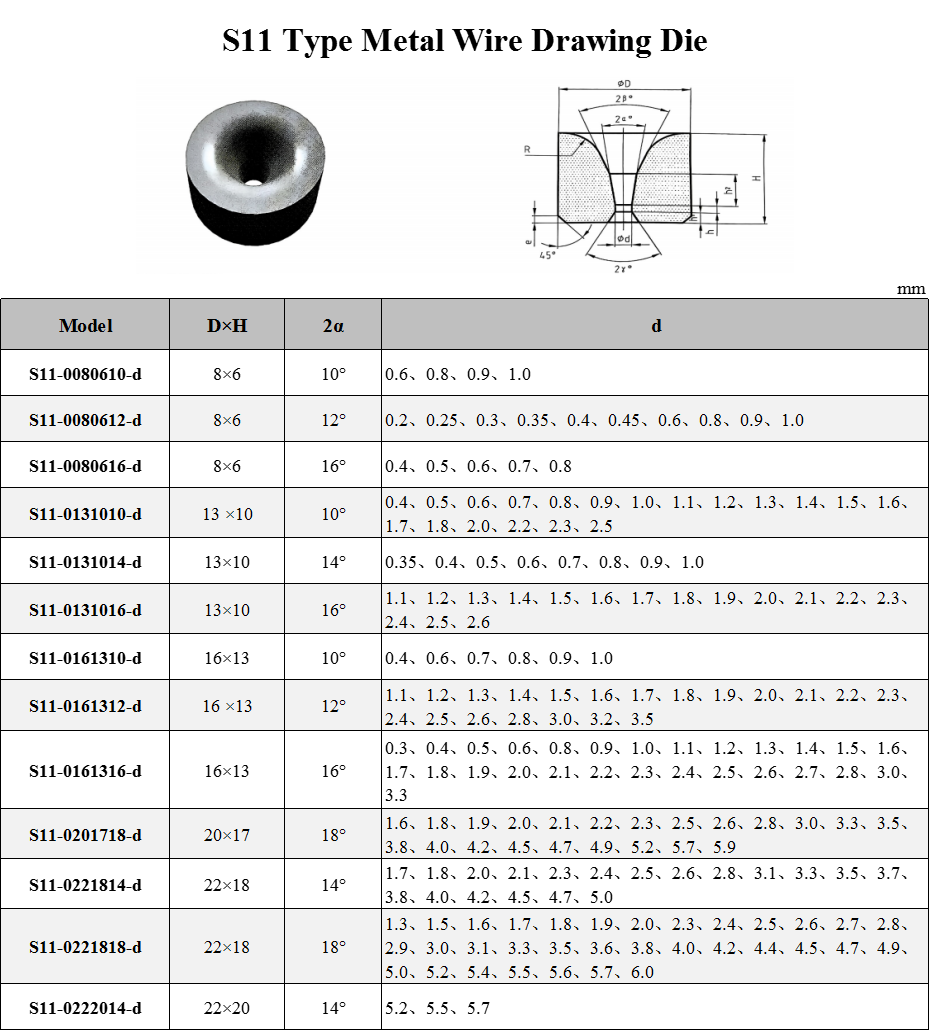

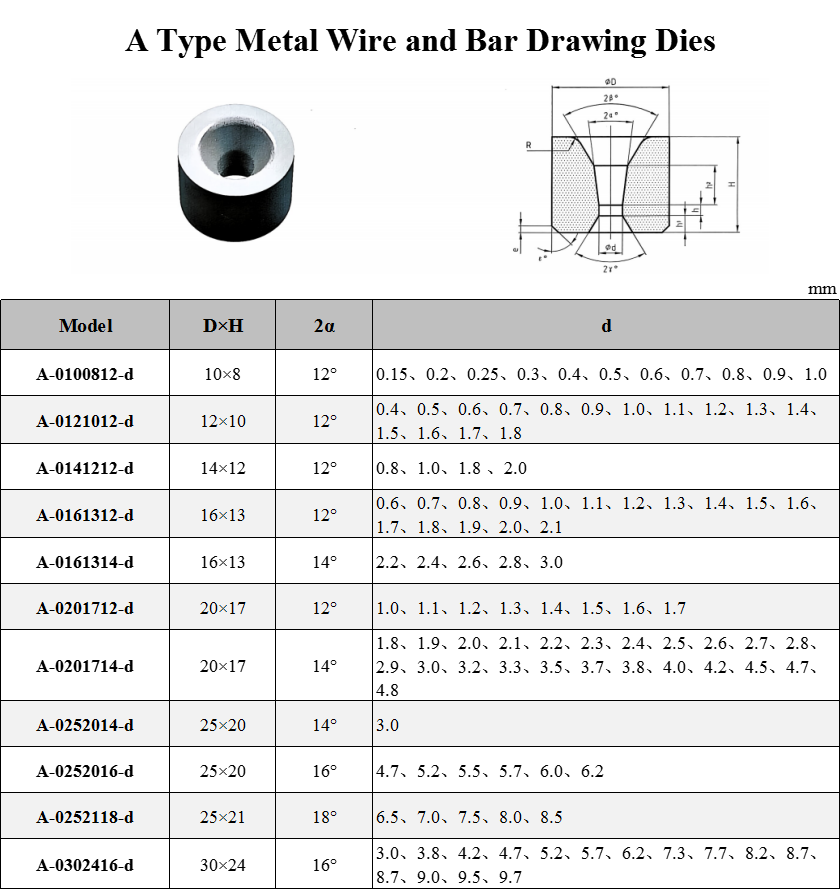

Tungsten Carbide Drawing Die Model Specification

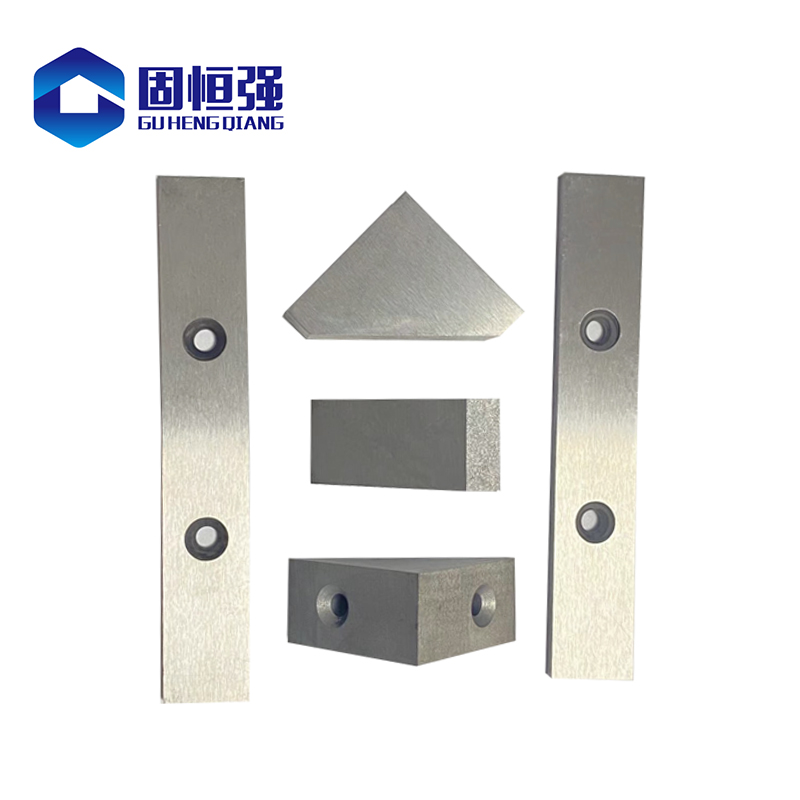

Cemented Carbide Drawing Dies Customized Instructions

1.Customized according to your sample or drawing;

2.According to your working conditions to provide you with grades and provide design solutions, with professional solution to the actual needs of customers!

Our company produces cemented carbide products, a variety of specifications, welcome to order! For you to comprehensively solve the production problems!

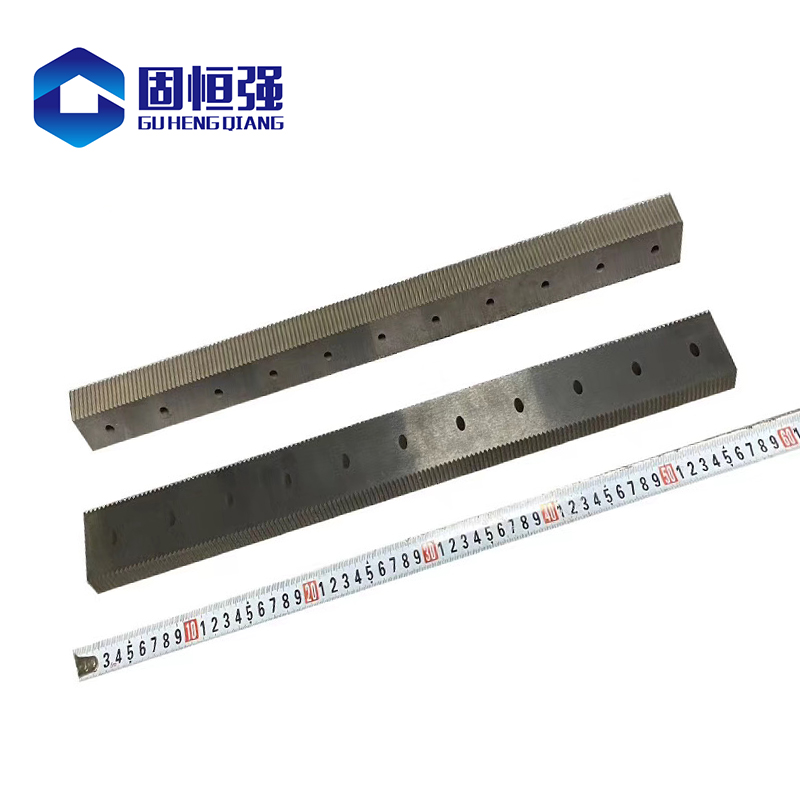

Precautions for the Use of Molds and Processing

1, must choose the shape and size of the mold suitable for the material to be drawn, otherwise it will be easy to produce cracks in the mold.

2, the mold must be correctly fastened along the stretching direction, can not be skewed to prevent uneven wear.

3, the lubricant on the mold life has a greater impact, choose the appropriate lubricant and keep the mold in a clean state to use.

4.Don't knock or drop the mold.

5, round processing need to ensure that the product of a single feed less than 0.2mm, to avoid excessive processing stress.

6, after processing the need to keep the surface dry, to avoid corrosion of the product white spots, it is recommended to use water/alcohol and other neutral media to clean the mold core, and blow dry or dry in a timely manner.

7, the core set set when the amount of surplus should not be too large, and avoid knocking the core.