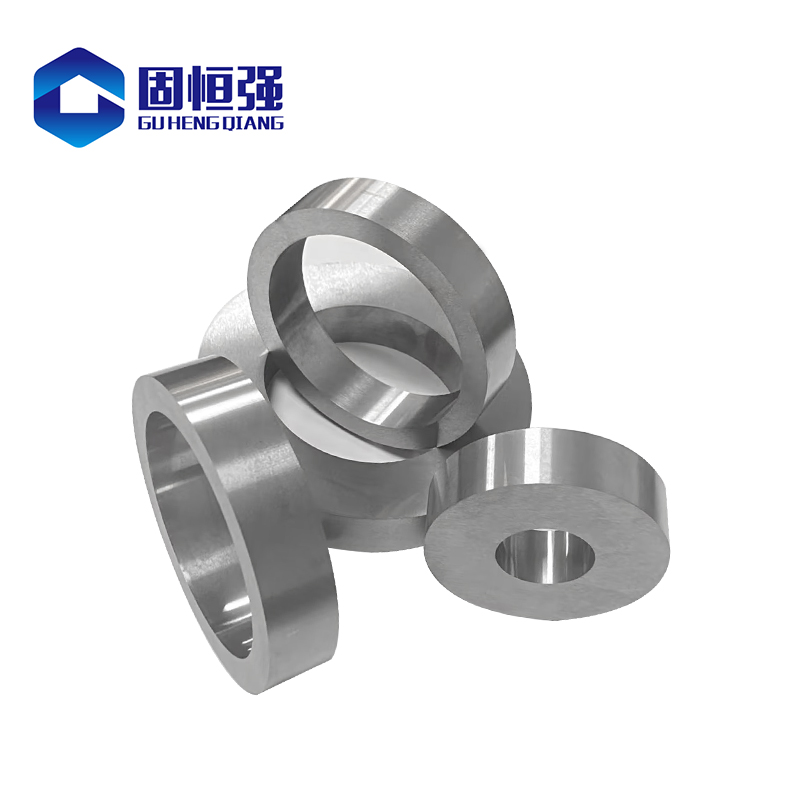

Cemented Carbide Composite Rolls Wear Corrosion

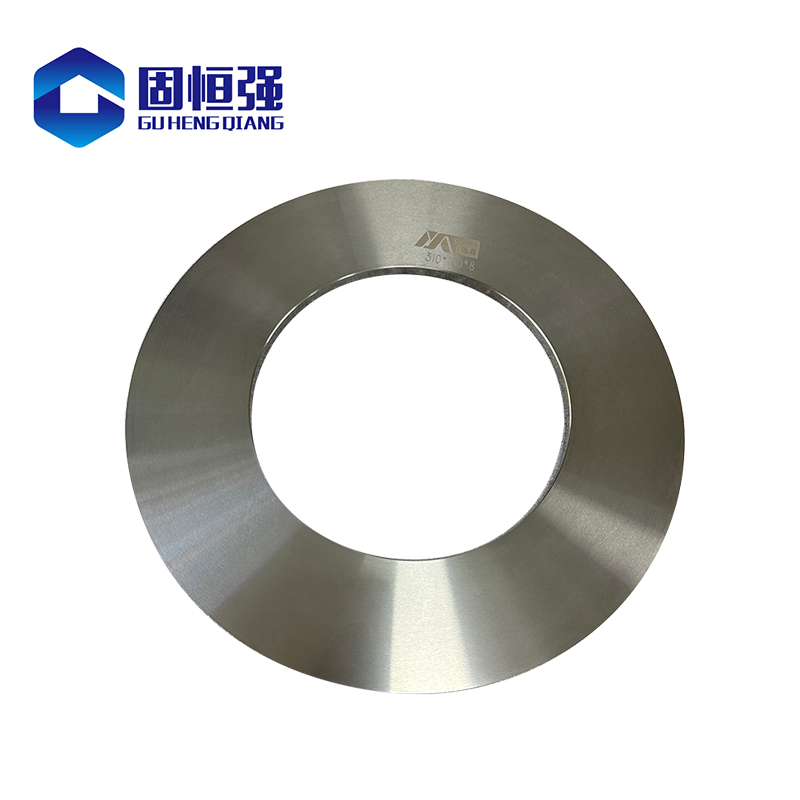

Introduction to High Wire Rolls

1. Carbide roll ring has high hardness, good abrasion resistance, high modulus of elasticity, long service life and high cost performance compared with steel roll ring, high dimensional accuracy of rolled products, excellent surface quality, which can greatly reduce the labour intensity of workers and improve production efficiency.

2. With the development of China's iron and steel industry, cemented carbide roll rings are widely used in the production of many products in the iron and steel industry, such as wire rod rolling, bar rolling, steel pipe rolling, small strip rolling, etc.

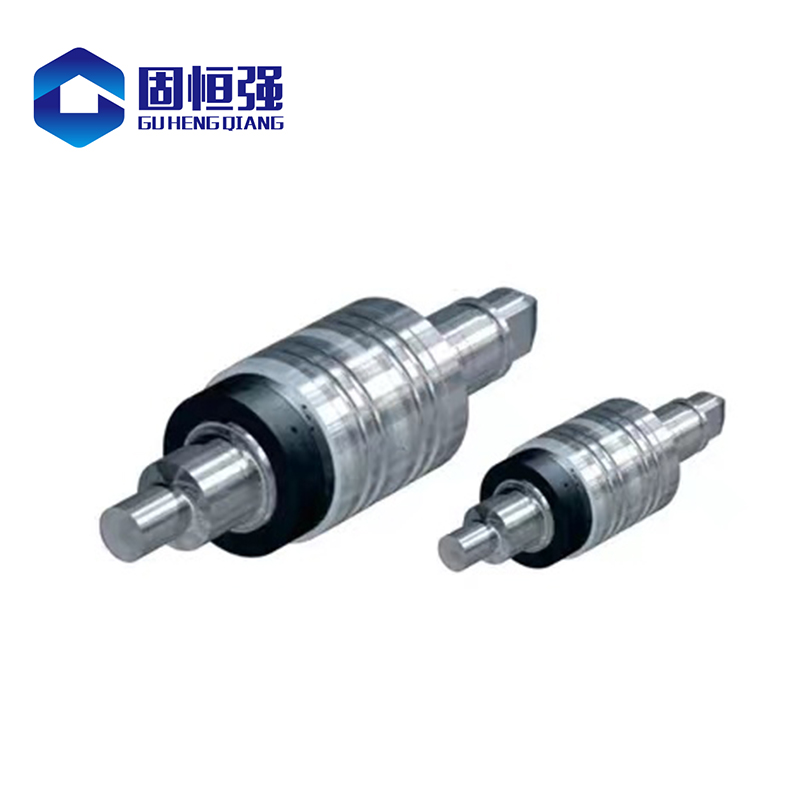

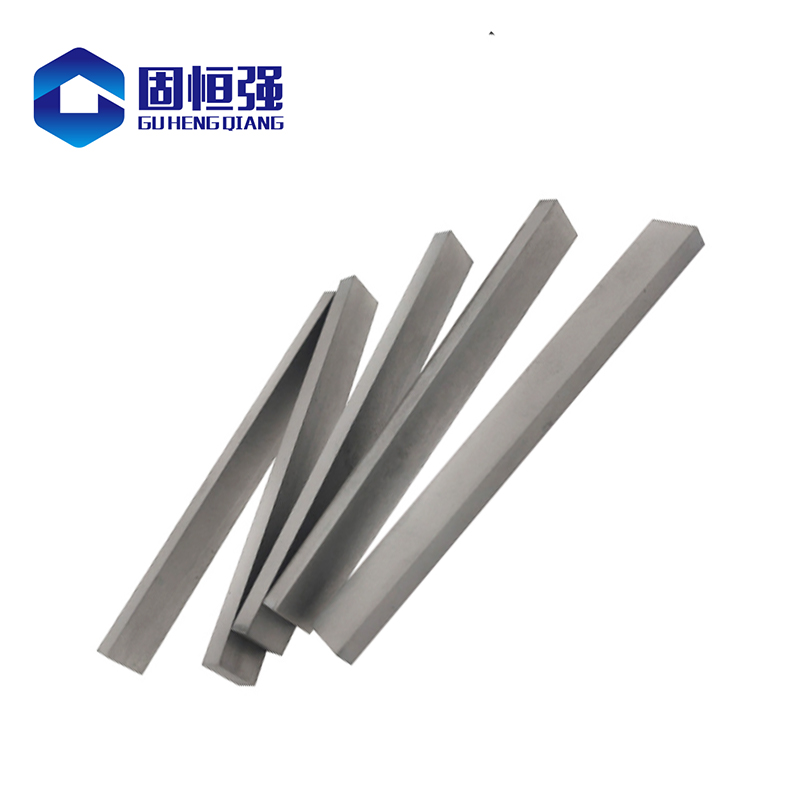

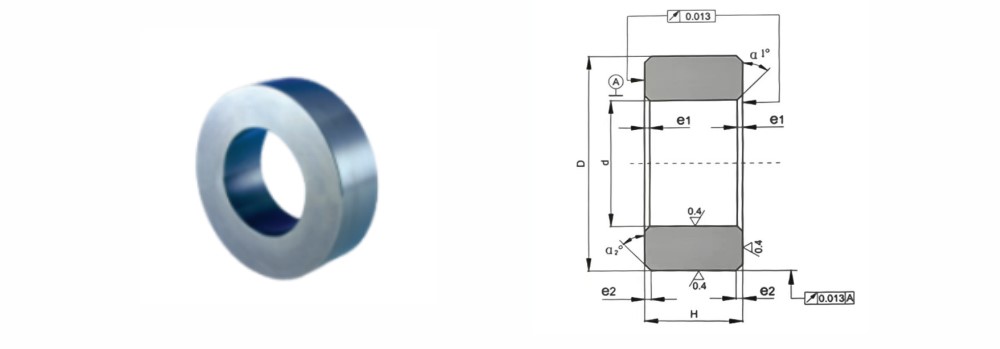

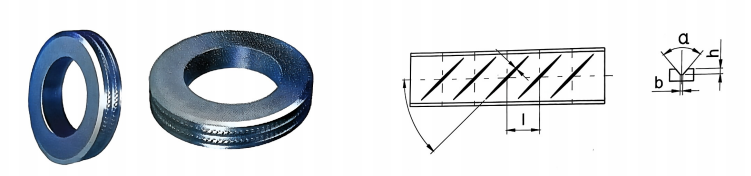

Roller Ring Types and Reference Drawings

1.Flat roller

| mm | ||

| Range of OD(D) | Range of ID(d) | Range of Height(H) |

| 120~470 | 70~310 | 40~250 |

Allowable deviation of outer diameter, inner diameter and height of roll ring

| mm | ||||

| Accuracy level | Grade 1 | Grade 2 | Grade 3 | Grade 4 |

| Outer diameter(±) | 0.02 | 0.05 | 0.10 | 0.15 |

| Inter diameter(+) | IT5 | IT6 | 1T7 | IT8 |

| Height(-) | 0.03 | 0.1 | 0.20 | 0.5 |

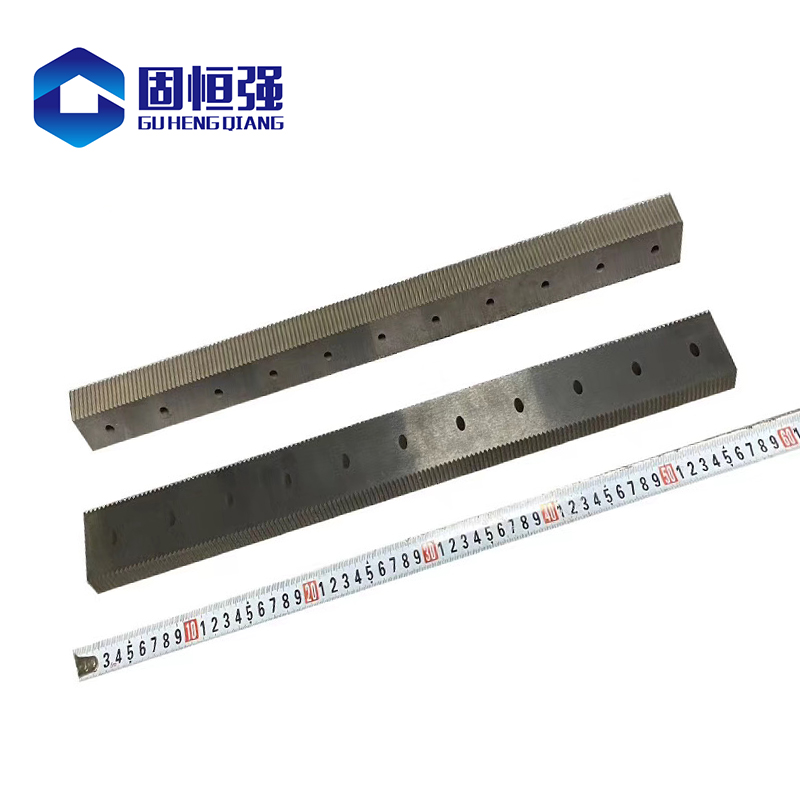

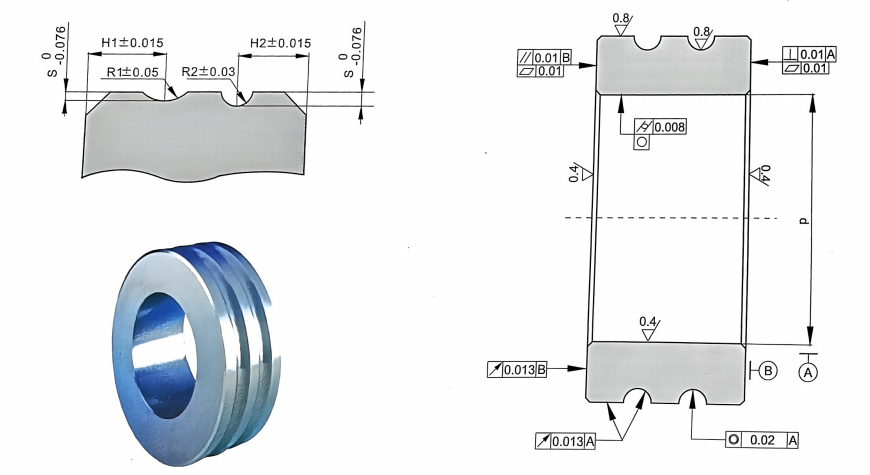

2.Slotting roller

3.Ribbed rollers

Allowable deviation of roll ring shape position:

| mm | |||||

| Radial runout of grooves | Radial runout of cylindrical | Face runout | Flatness of the end face | Parallelism of end faces | Cylindricity of bore |

| ≤0.013 | ≤0.02 | ≤0.01 | |||

Roll ring roughness:

| Bore roughness | Cylindrical roughness | Roughness of the end face |

| 0.4~0.8 | 0.8~1.6 | 0.4~0.8 |

The permissible deviation of outer diameter, inner diameter and height can be determined separately according to the requirements of users.

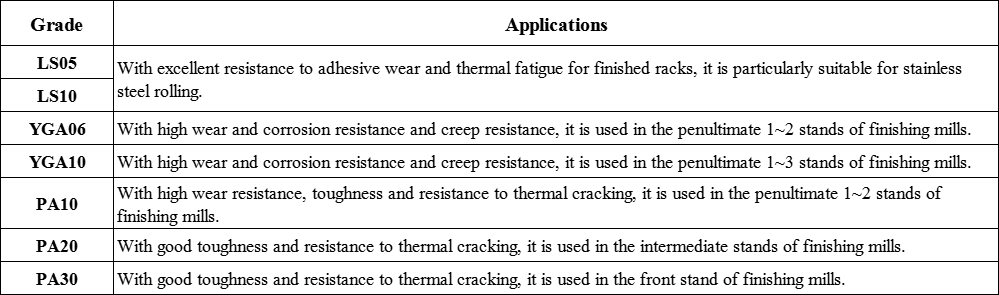

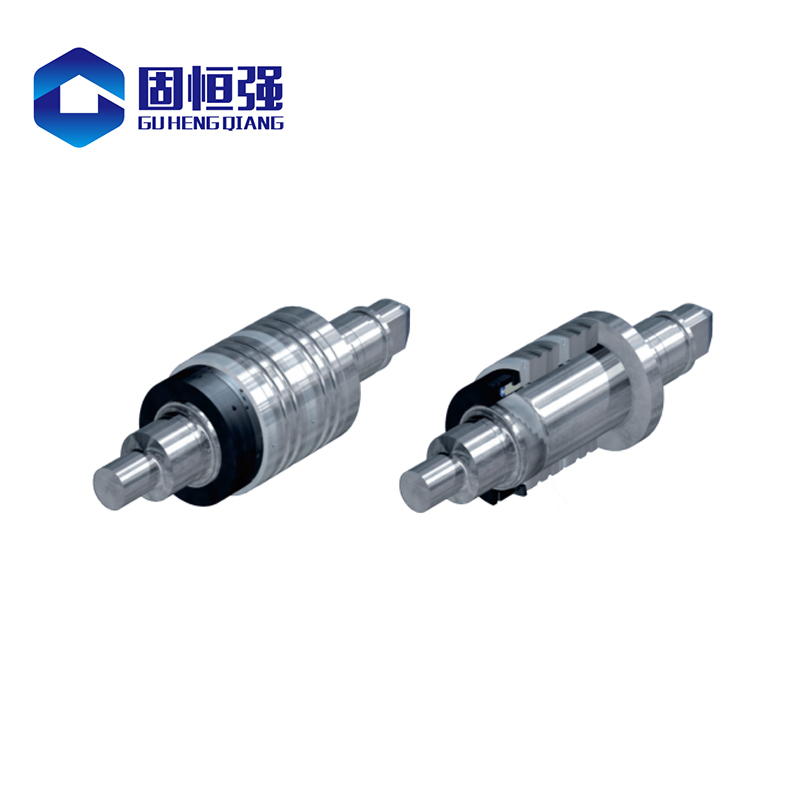

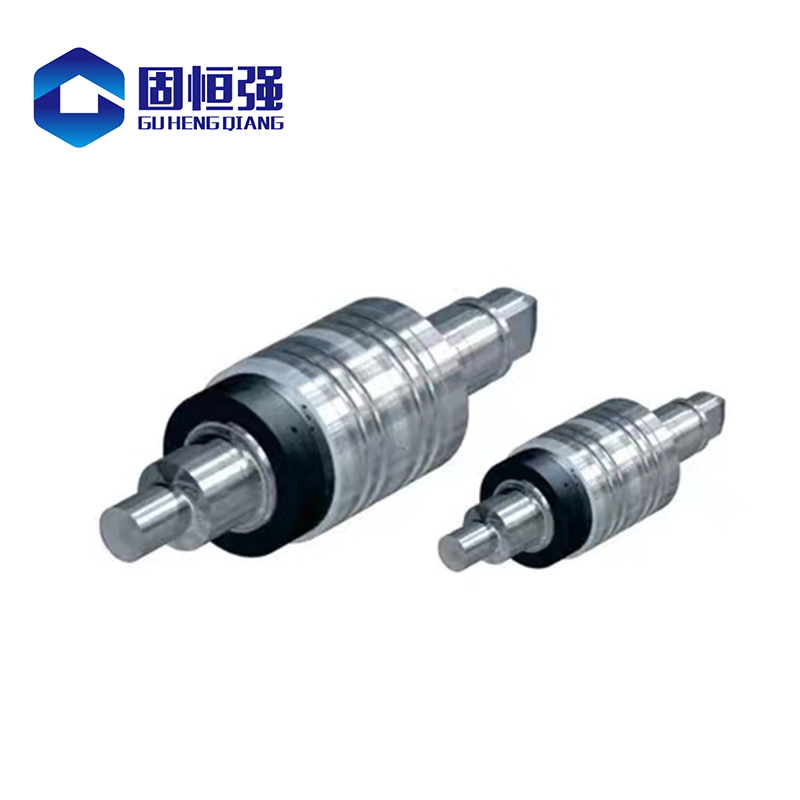

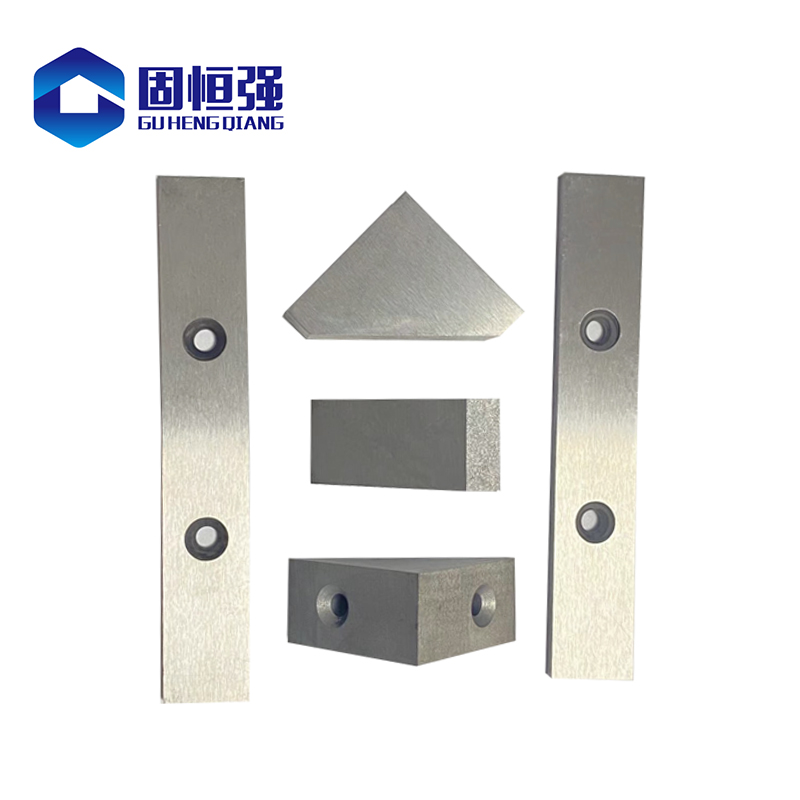

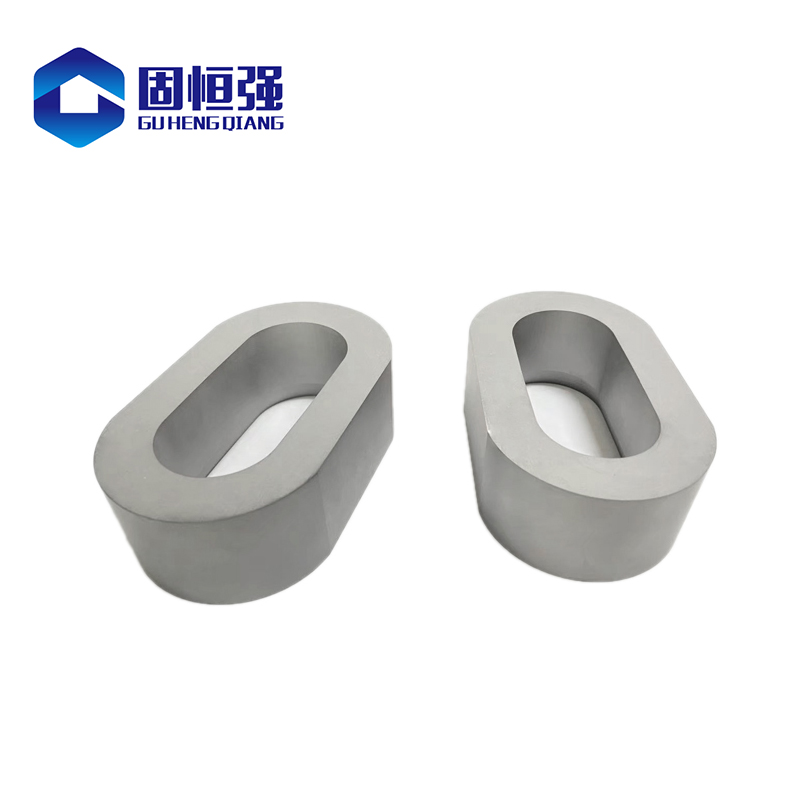

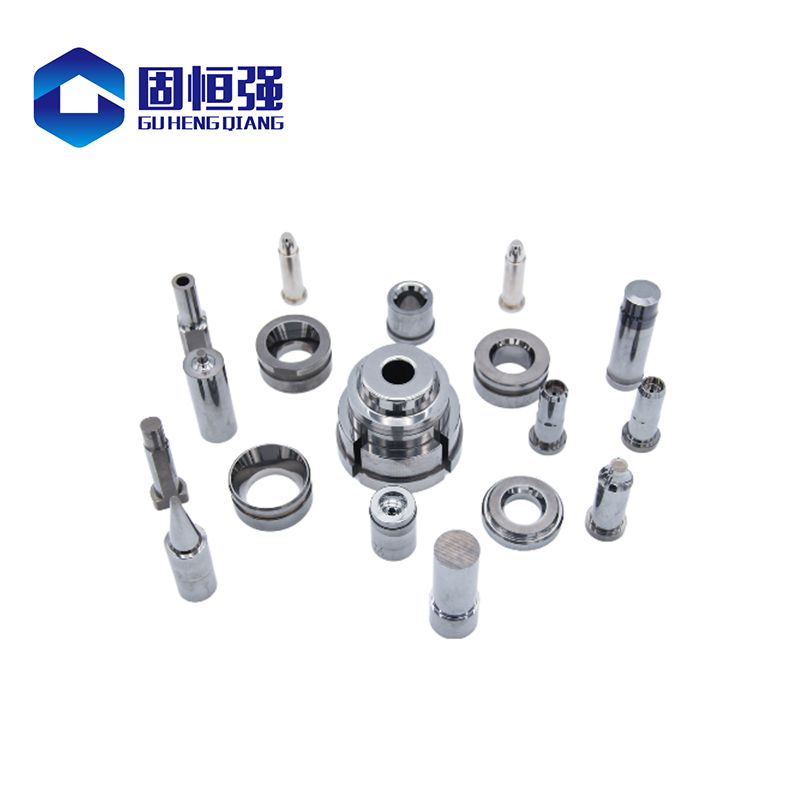

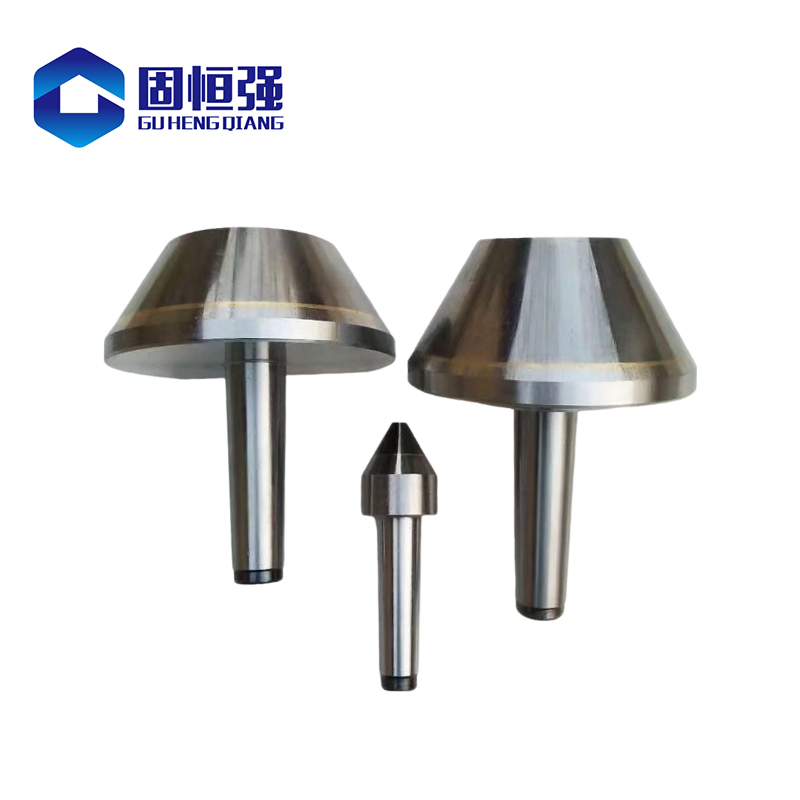

Introduction of Cemented Carbide Composite Rolls

1.Definition of Cemented Carbide Composite Rolls

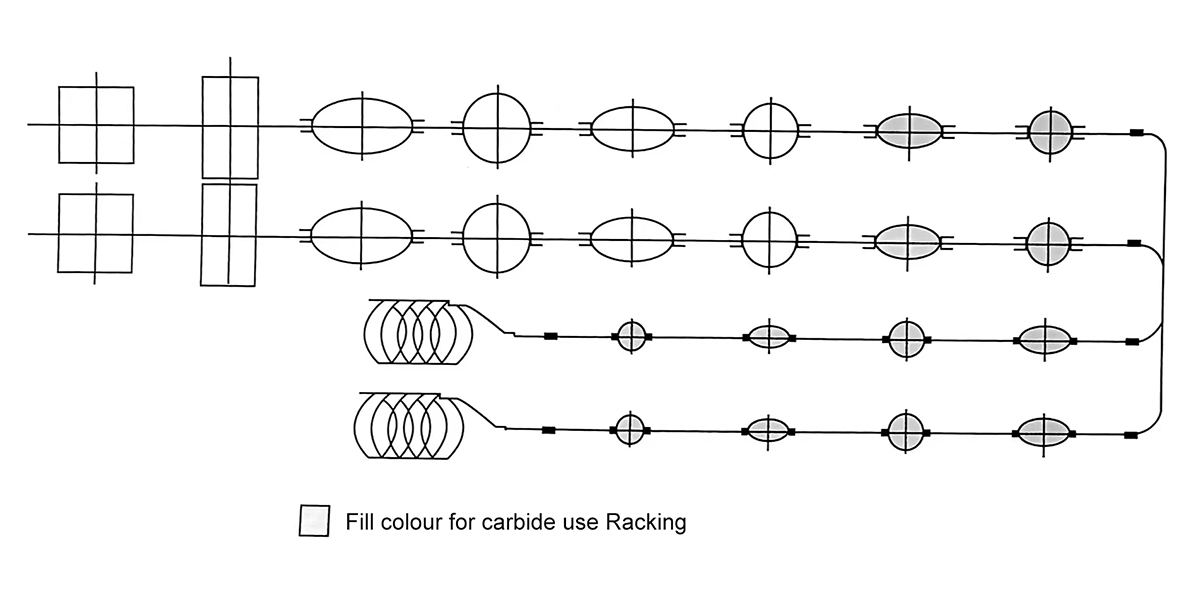

Composite rolls are made of carbide roll rings and matching steel shafts compounded or combined into one piece by special methods, and are used for rolling applicable round steel, rebar, square steel, flat steel, angle steel and other profiles.

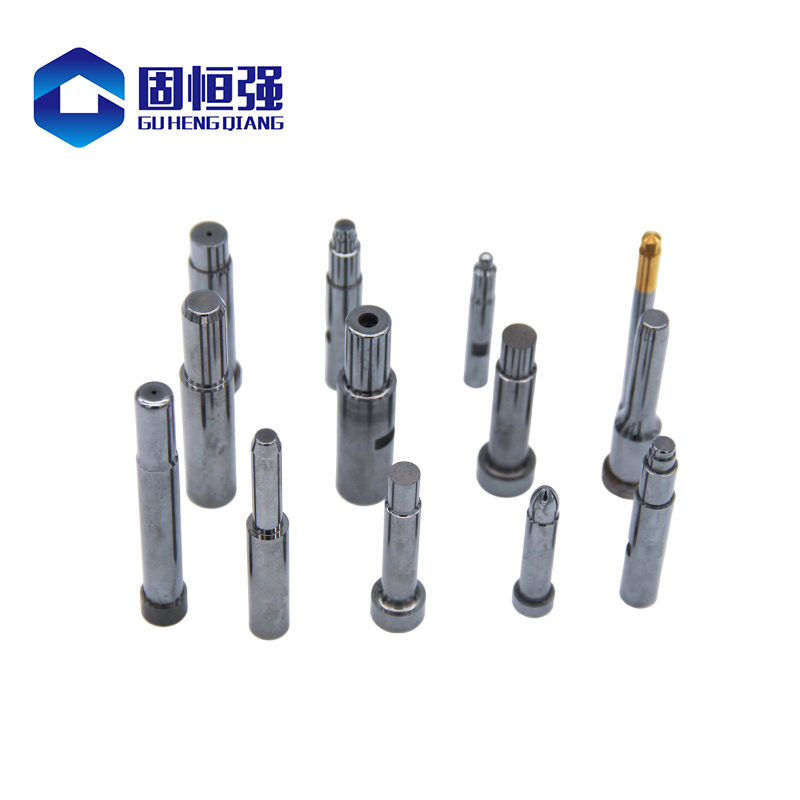

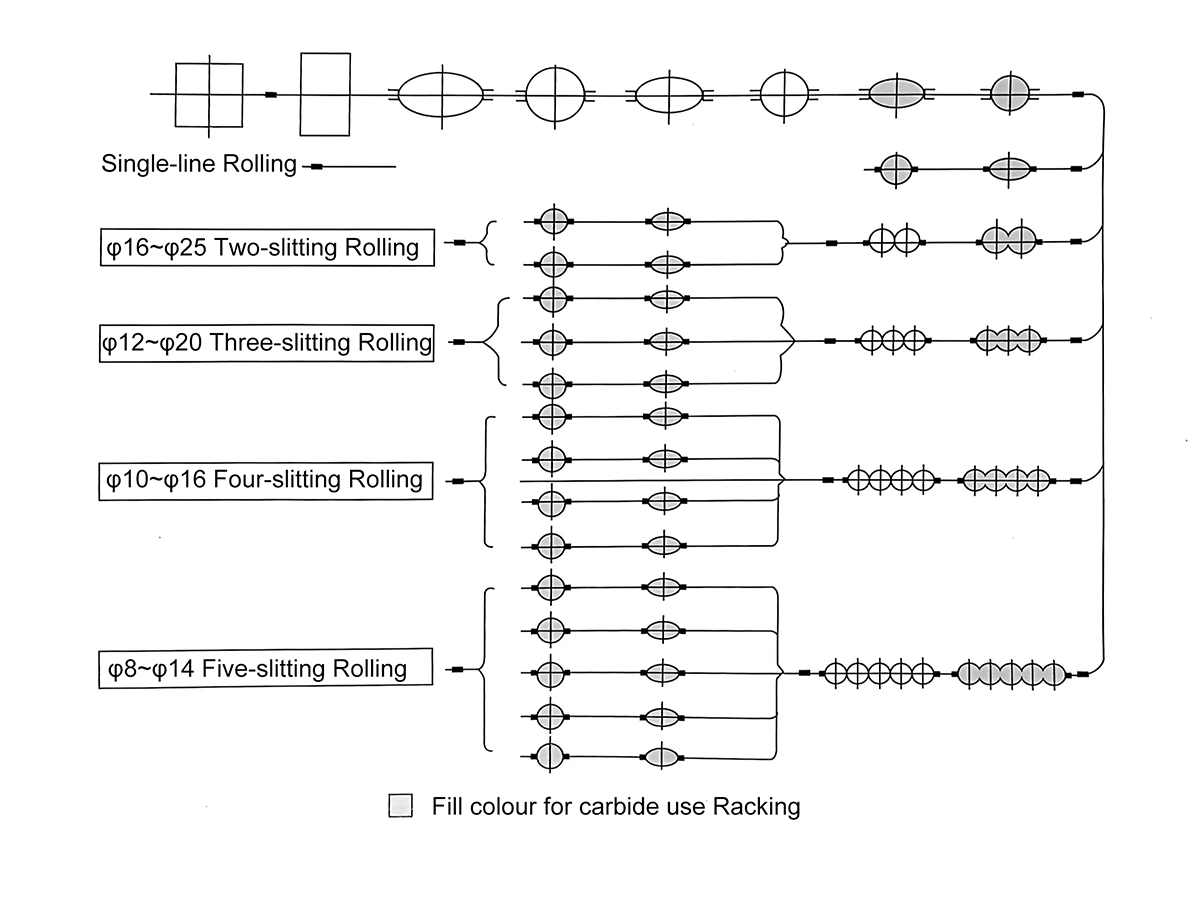

2.Scope of application of carbide composite rolls

Cemented carbide composite rolls are suitable for rolling speeds within 2-50m/s in conventional bar mills and bar wire disc mills, high-speed wire rod mills in the middle mill stand.

(1) Conventional bar mills: product racks, pre-slitter racks, and intermediate mill stands for conventional bar lines.

(2) Bar wire disc rolling mill: for bar wire disc rolling mill finishing mill stand, middle rolling mill stand.

3.Advantages of Cemented Carbide Composite Rolls

(1) Enhance the quality of steel products, so that the surface quality and tolerance of rolled products have been thoroughly improved, and the negative deviation control is very accurate.

(2) Reducing the number of groove and roll changes and downtime, reducing the labour intensity of the rolling shop staff, enhancing the mill's production utilisation and output, and enabling the mill to create greater economic benefits within the same time; and

(3) Improve the product yield rate; and

(4) Reduce the cost of tonnes of steel, which is an effective way to reduce costs and increase efficiency.

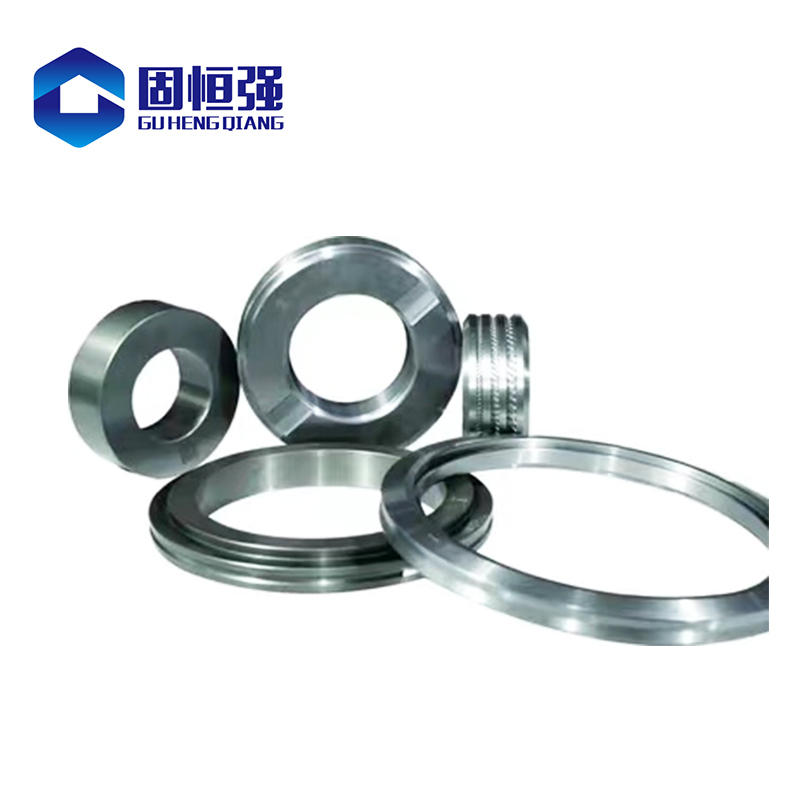

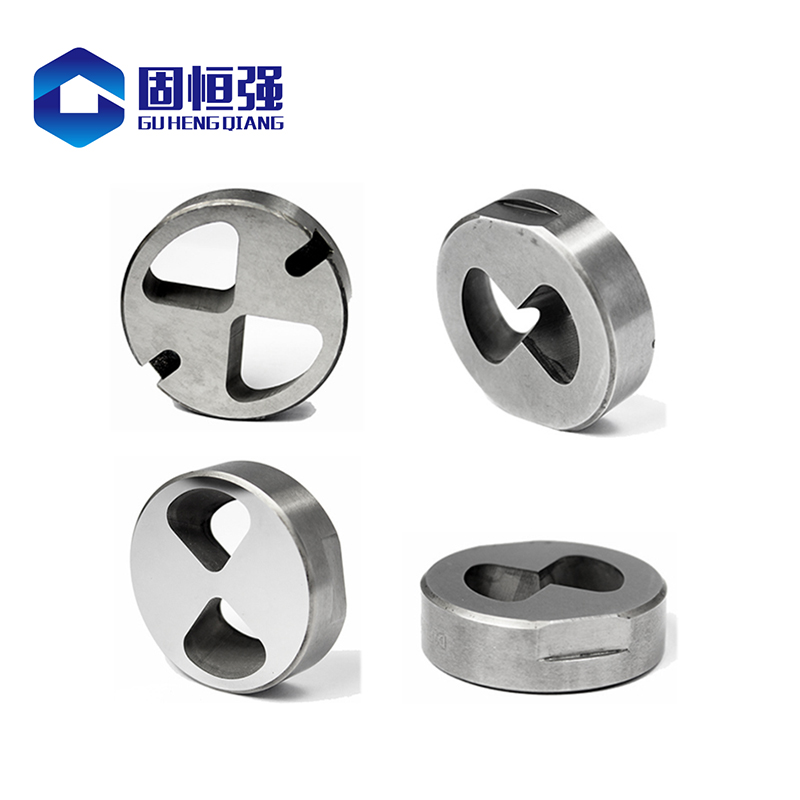

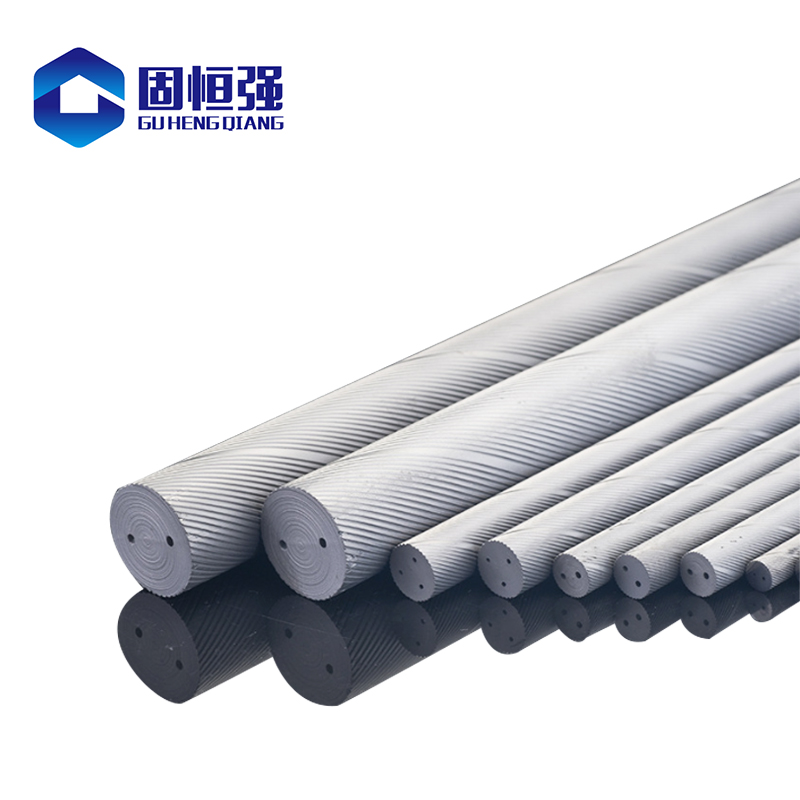

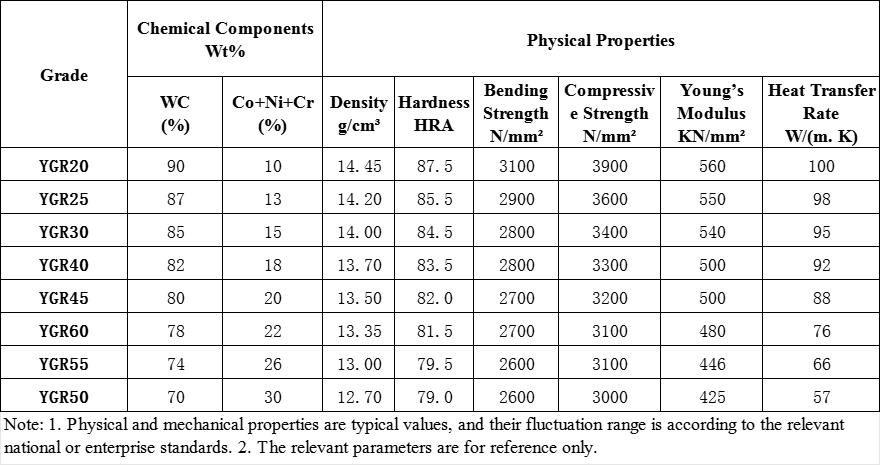

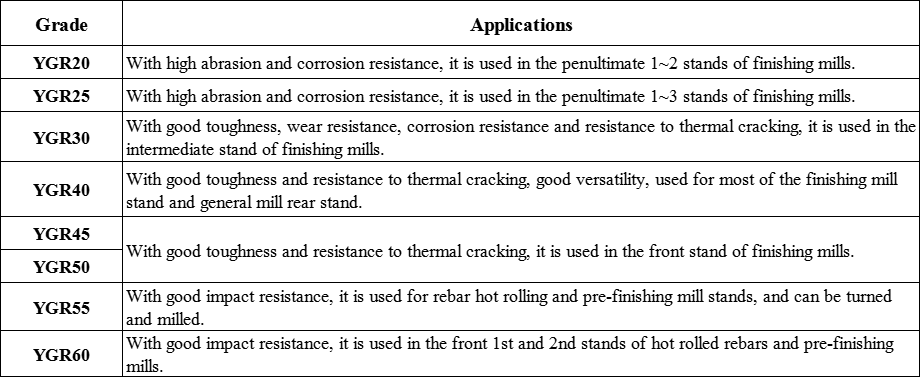

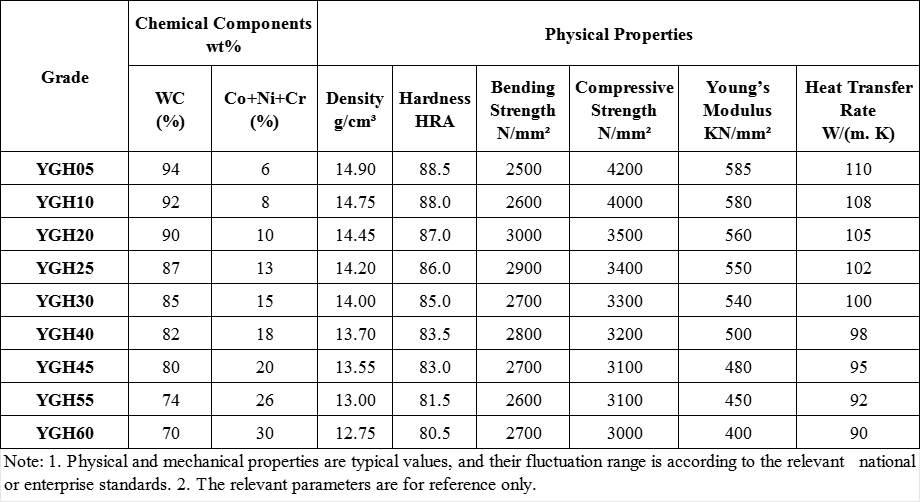

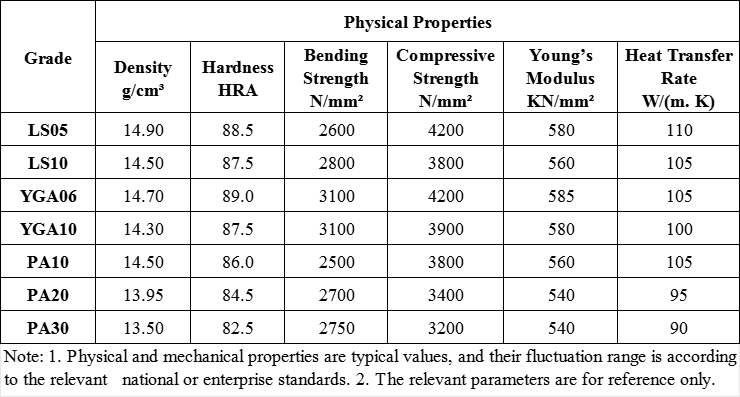

4.Composition and properties of carbide roll ring grades for composite rolls.

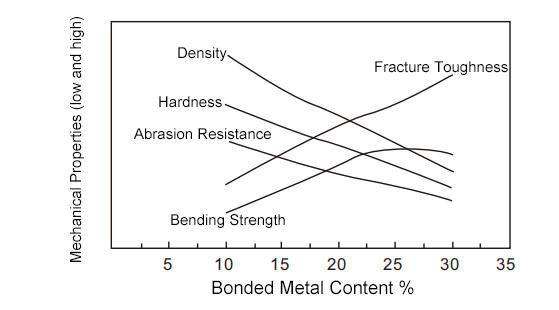

The main components of Cemented Carbide are tungsten carbide particles and metal binder (often cobalt), and nickel and chromium are added when needed to improve its resistance to thermal cracking and corrosion resistance. Different binder contents and corresponding WC particle sizes result in different carbide grades. The company has a series of carbide roll ring grades suitable for different stands in different mills.

The general relationship between the physical and mechanical properties of Cemented Carbide grades and the metal binder content.

Grades of Roller Ring

Classic Universal Roller Ring Series Grades

Classic general-purpose roller ring series: Adopting Co-Ni-Cr as the binder phase, it has high wear and corrosion resistance and versatility.

High-performance Roller Ring Series Grades

High-performance roller ring series: using pure Co as the binder phase, compared with the classic general-purpose roller ring series, the strength and toughness of the roller ring is better, and the wear resistance is higher, but there are certain requirements for the working conditions at the use site and the cooling water quality (weak alkaline environment with PH ≥ 7.2).

Roller Ring Series for Superior Steel Rolling

Specialised roll ring series for superior steel rolling: coarse crystal WC is used, with high resistance to thermal cracking properties and high toughness. Suitable for rolling various high-quality steel grades.