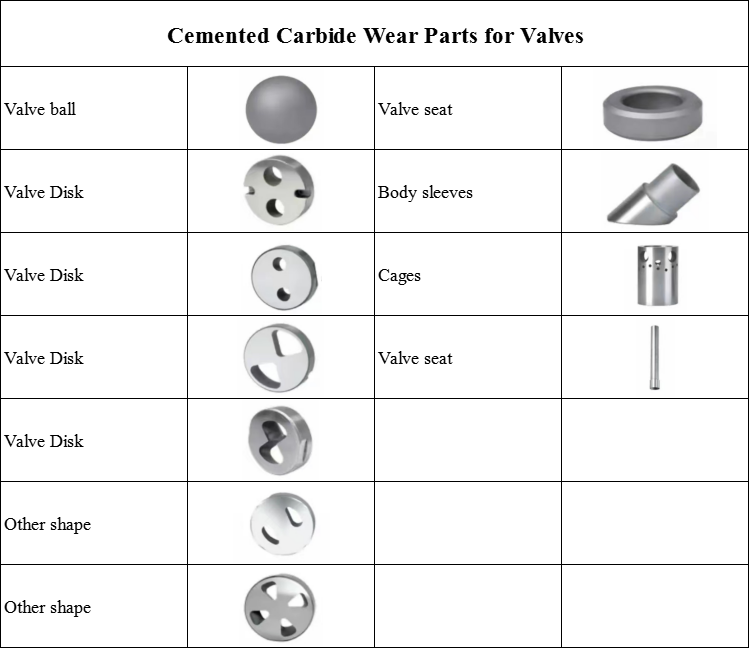

Carbide Wear Parts for Valves

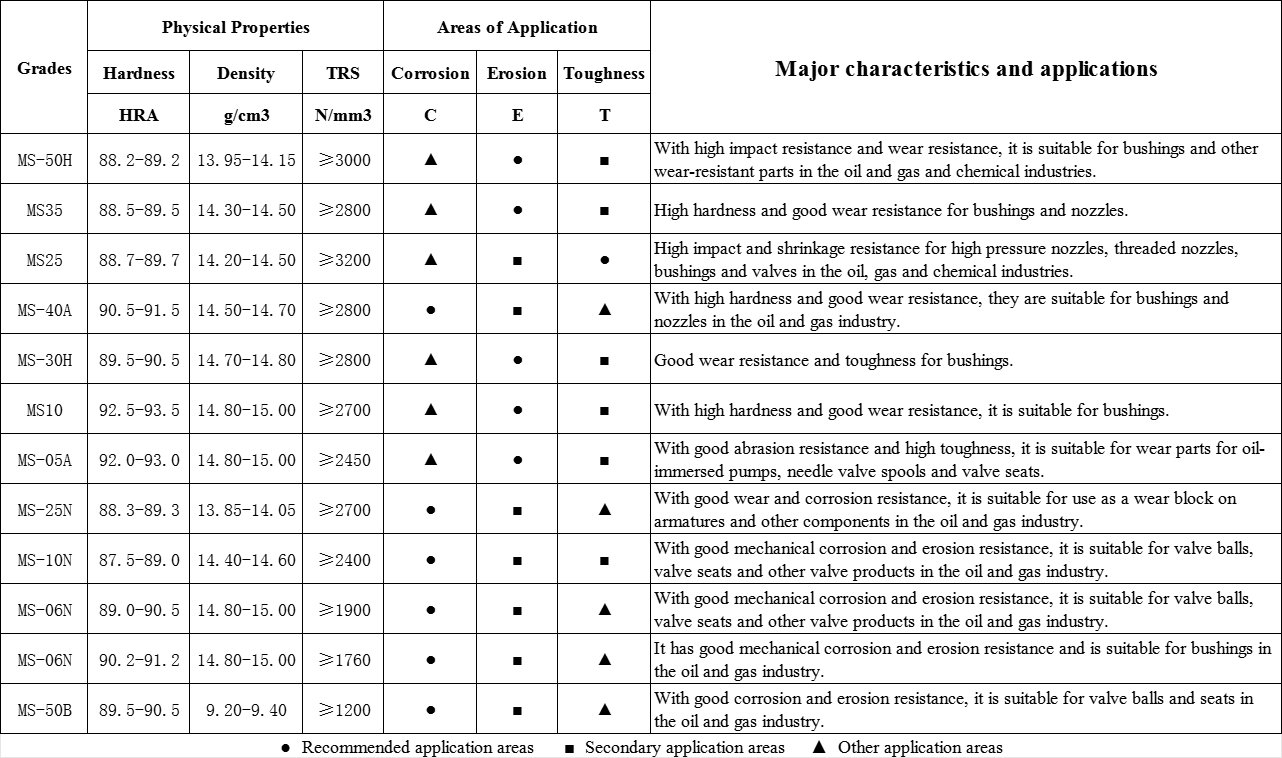

Cemented Carbide Material Properties

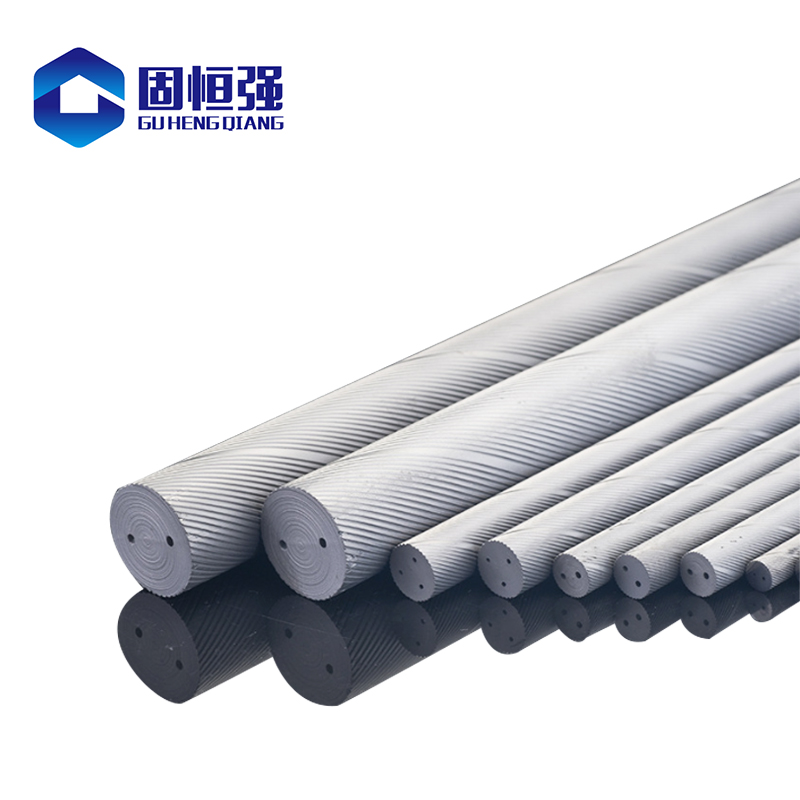

Cemented Carbide is a smart material for a wide range of needs as its composition can be varied to ensure maximum blend of wear resistance, deformability, corrosion, erosion, fracture and toughness.

The oil and gas industry has been exposed to harsh environments such as corrosive, erosive, impact, high pressure and high temperature. Therefore, Cemented Carbide will be the best choice for wear resistant solutions in the oil and gas industry.

Cemented Carbide Wear-resistant Parts Grade

Carbide Wear Parts for Valves Introductions

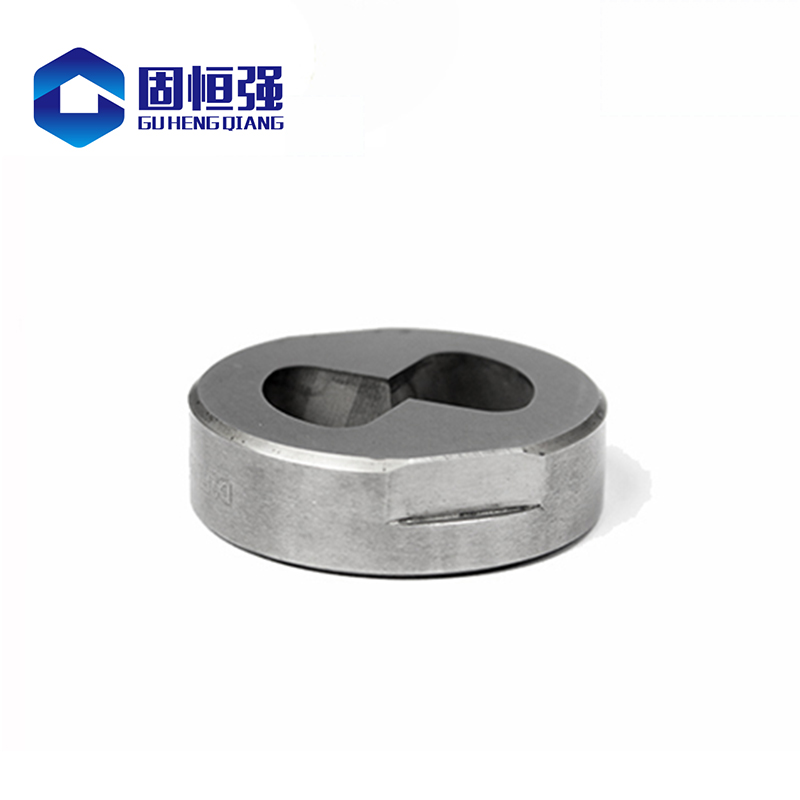

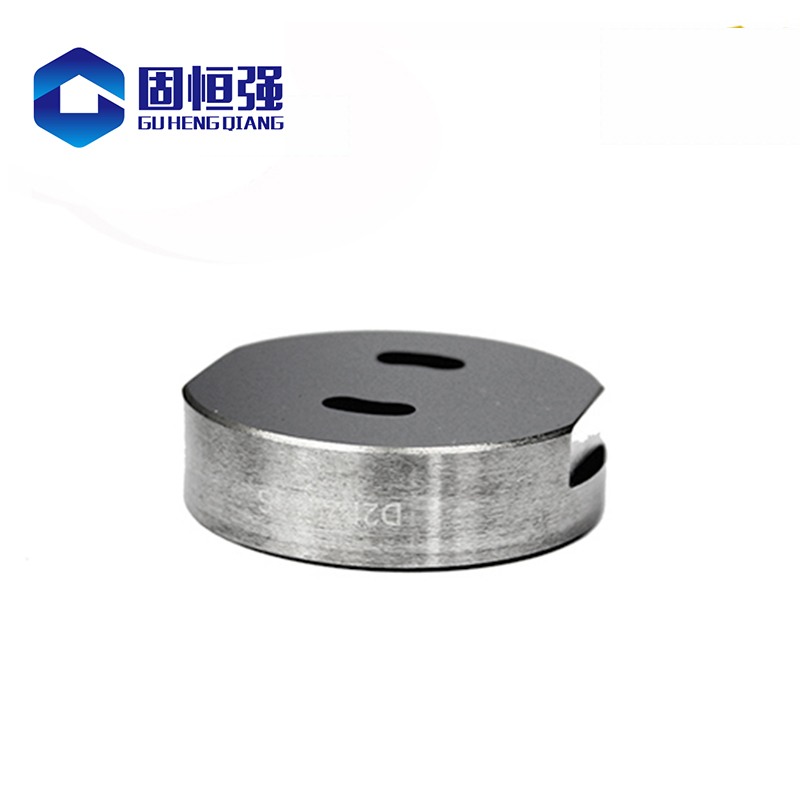

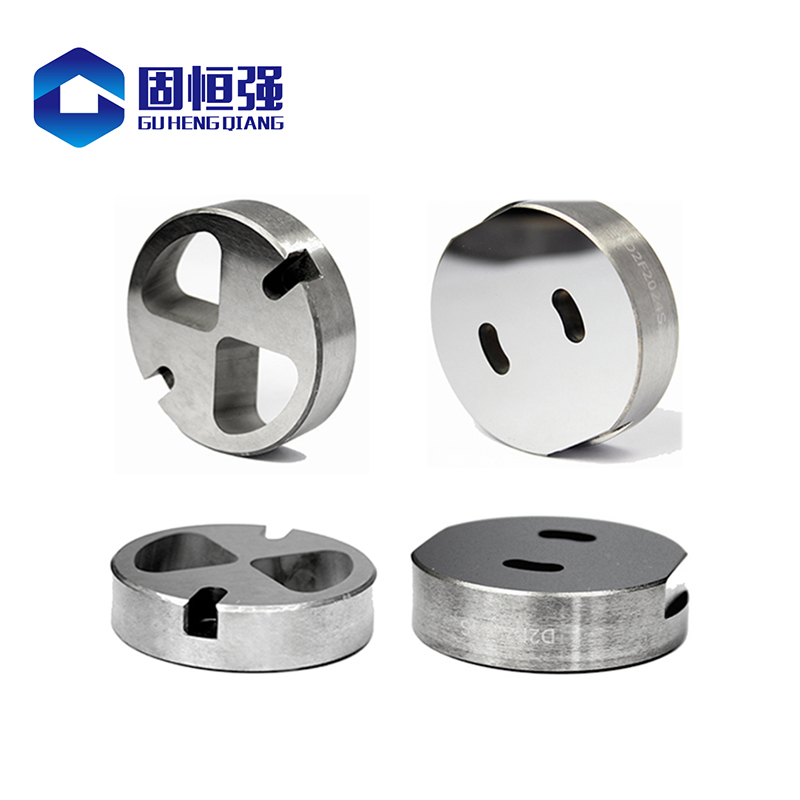

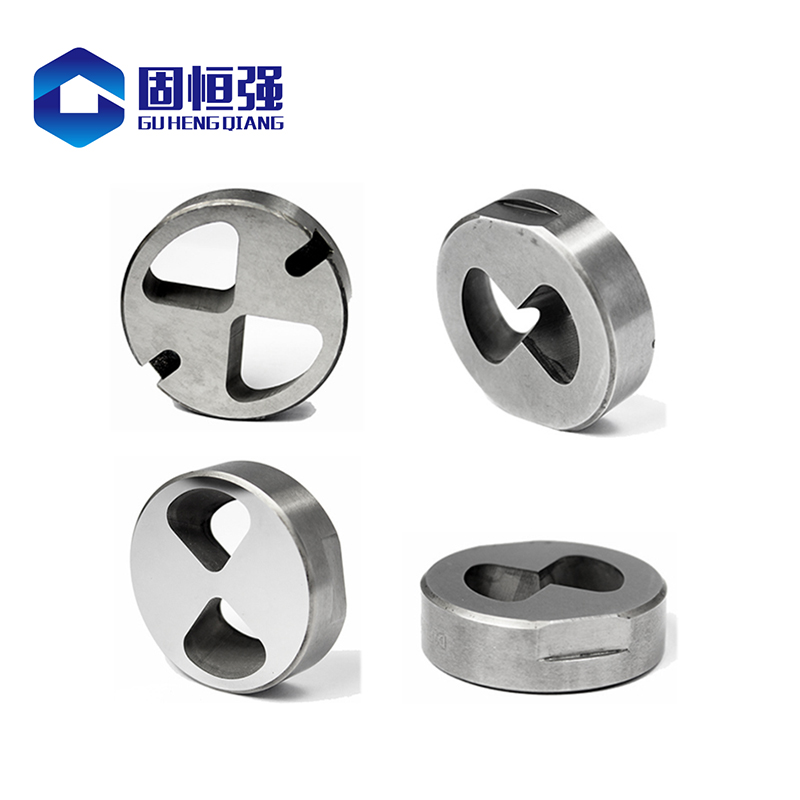

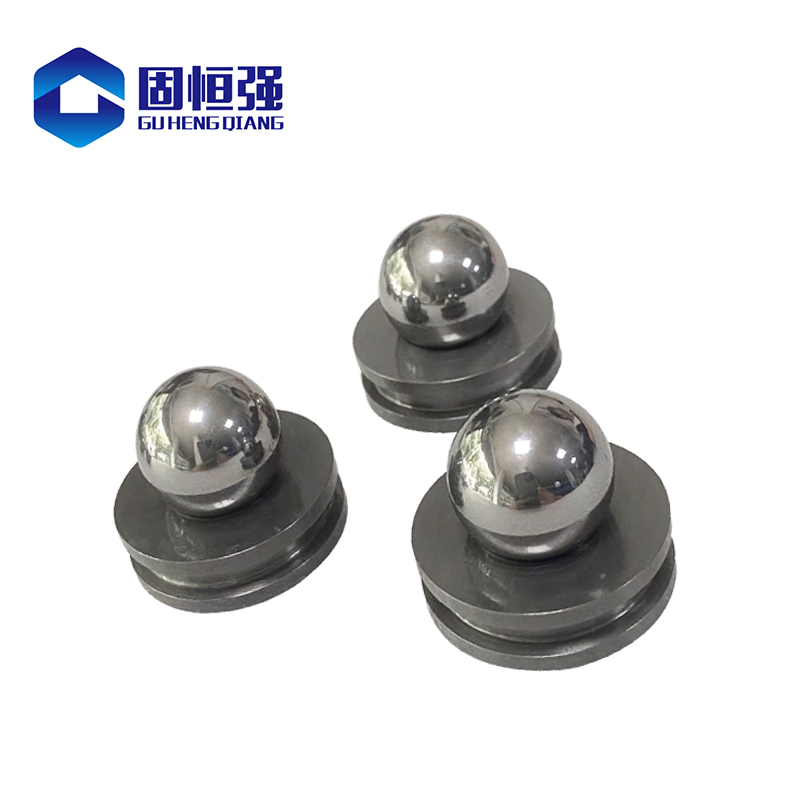

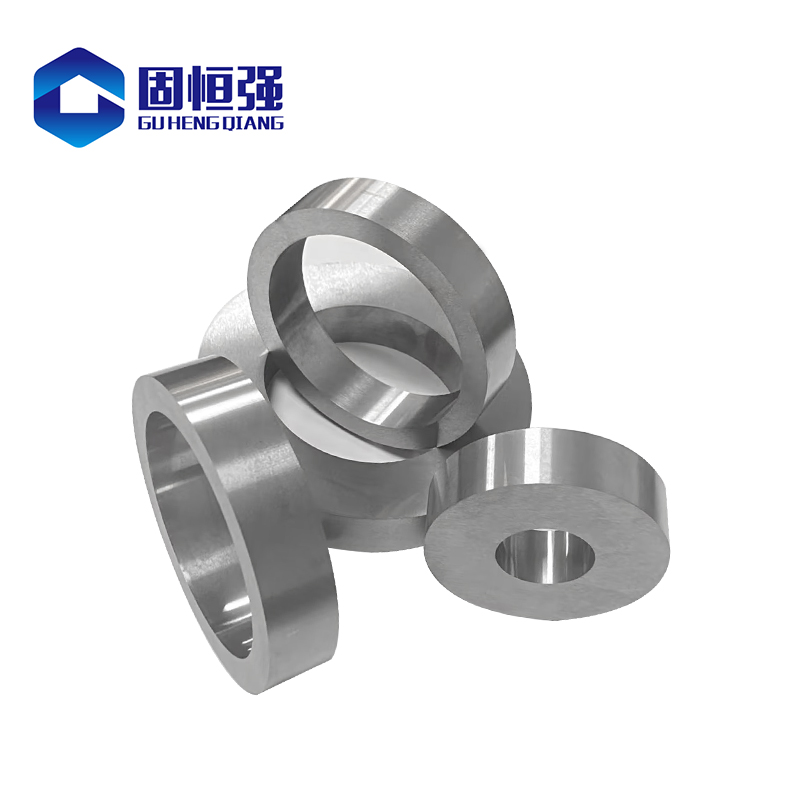

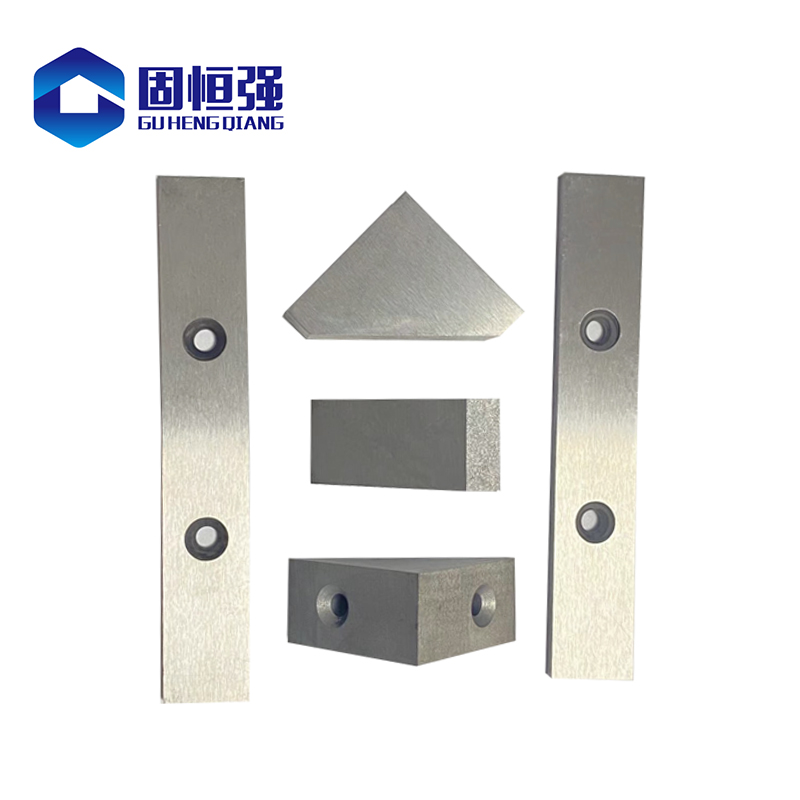

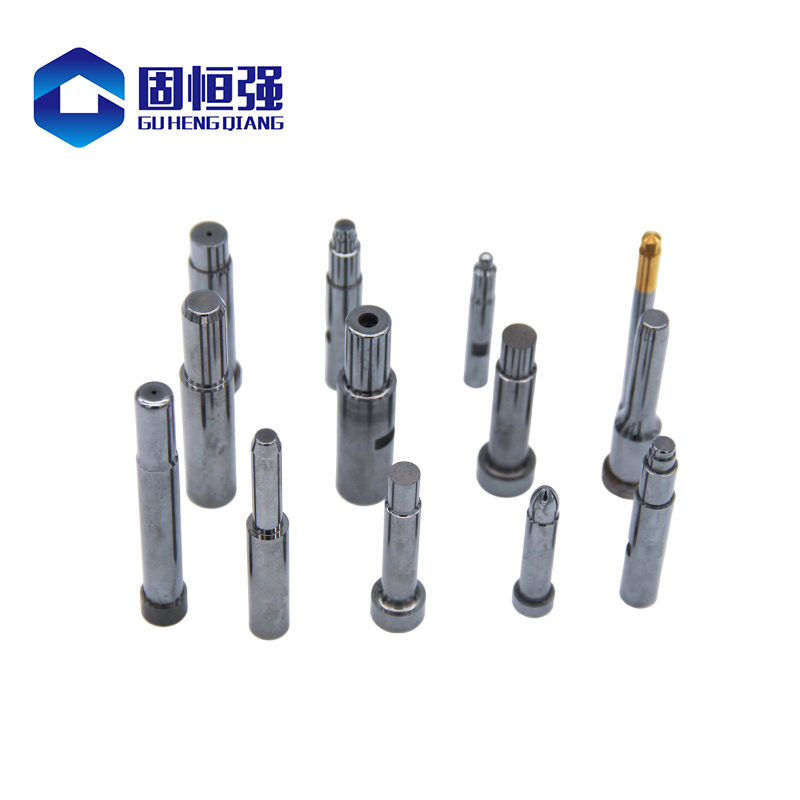

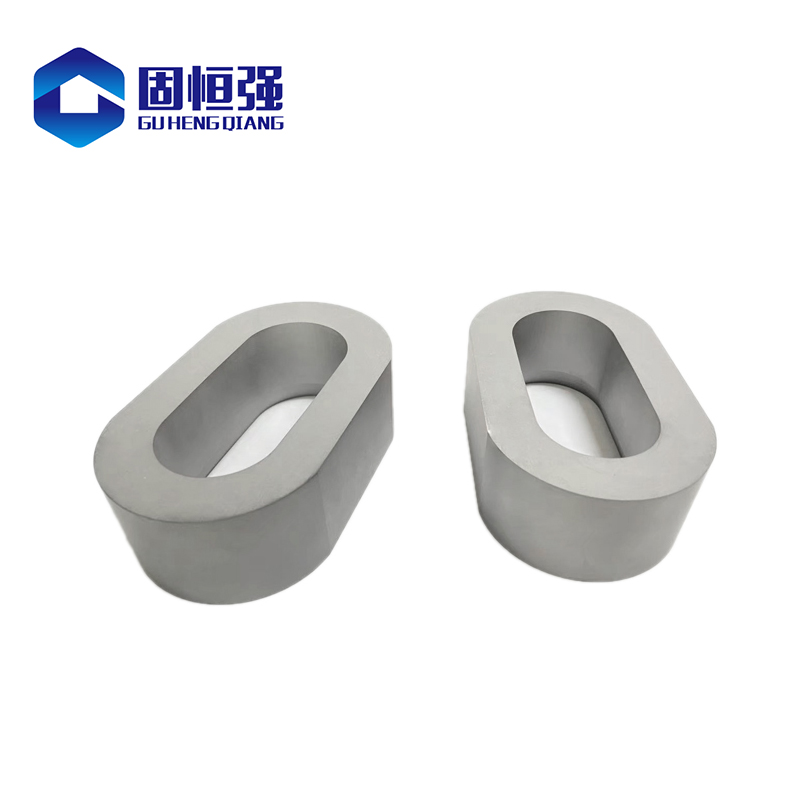

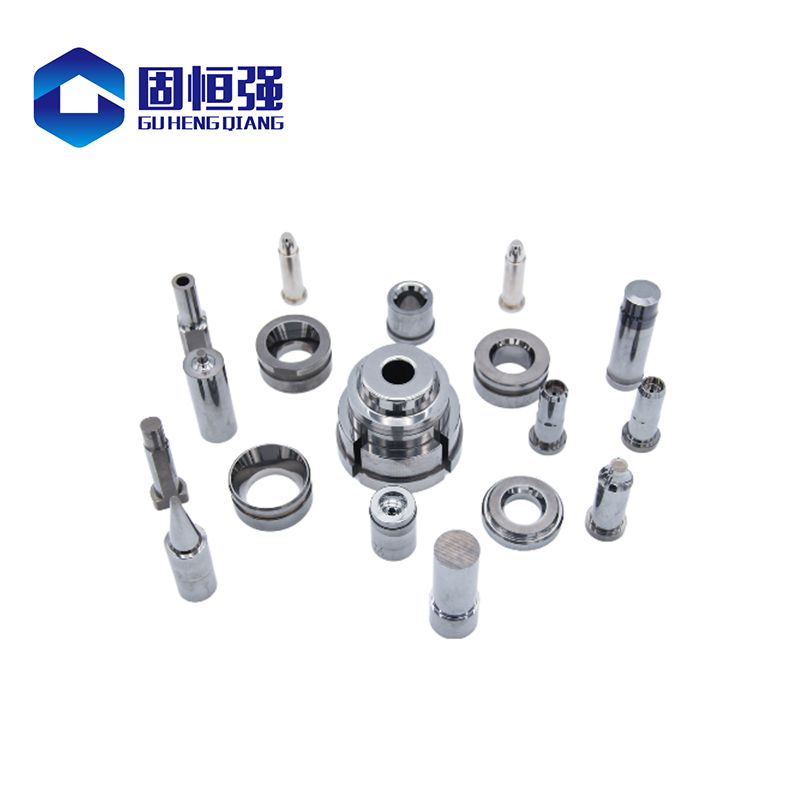

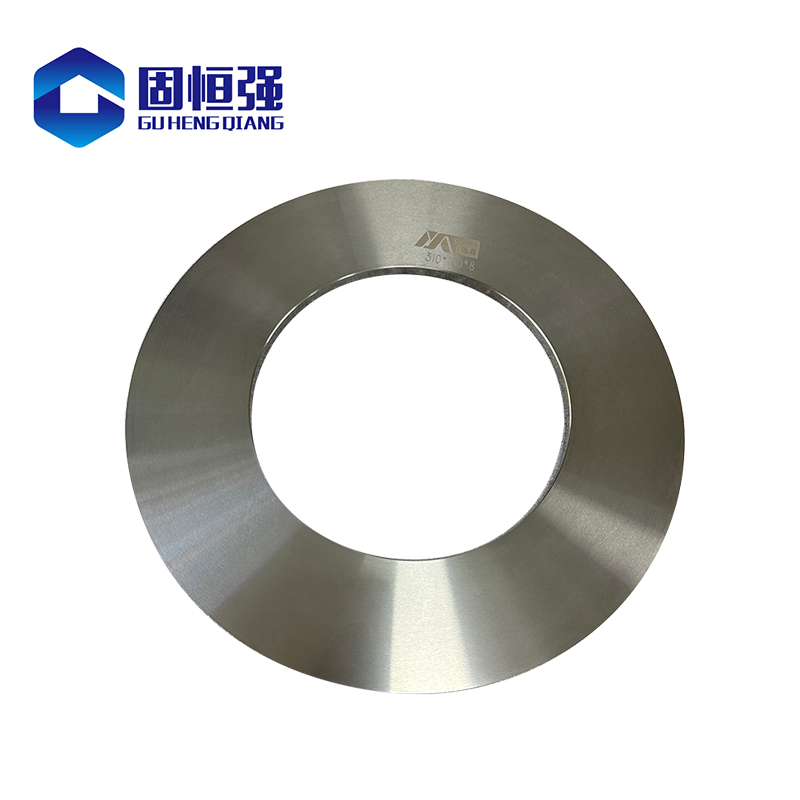

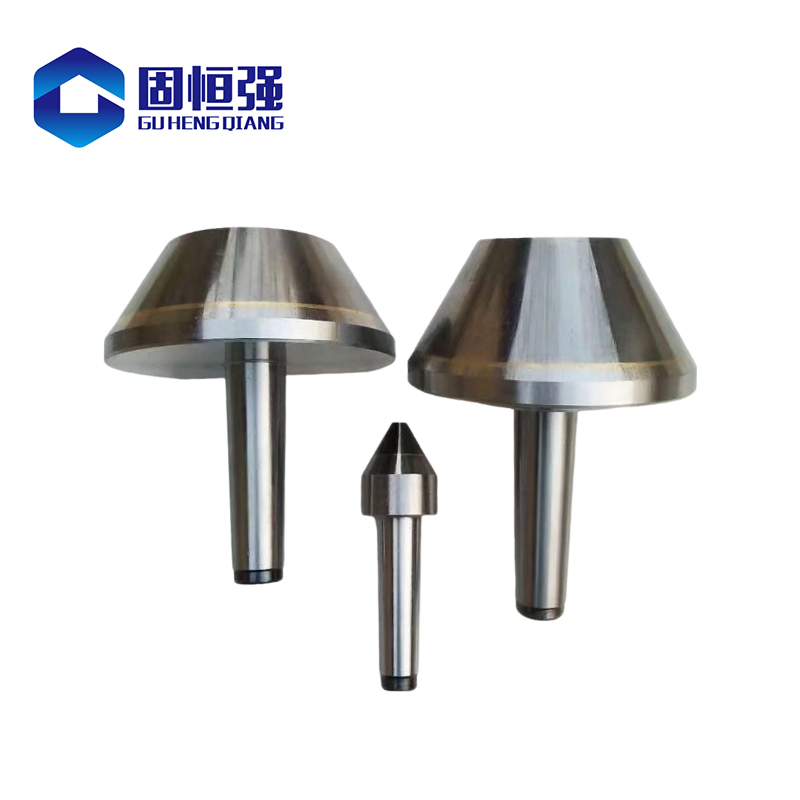

1.Wear parts for valves mainly include: throttle plate, ball valve spool, ball valve seat and other parts that require excellent corrosion and erosion resistance.

2.Throttle plates are widely used in throttle and regulator valves for precise control of fluid volume and pressure.

3.Ball valve spools and seats are mainly used as fixed and travelling check valves in various tubular and rod pumps.

4.Cemented carbide valve ball valve seat has the characteristics of high hardness, wear and corrosion resistance, impact resistance, etc. Therefore, the pumping effect is good, and the pump inspection cycle of using cemented carbide products is longer, more efficient and stable.

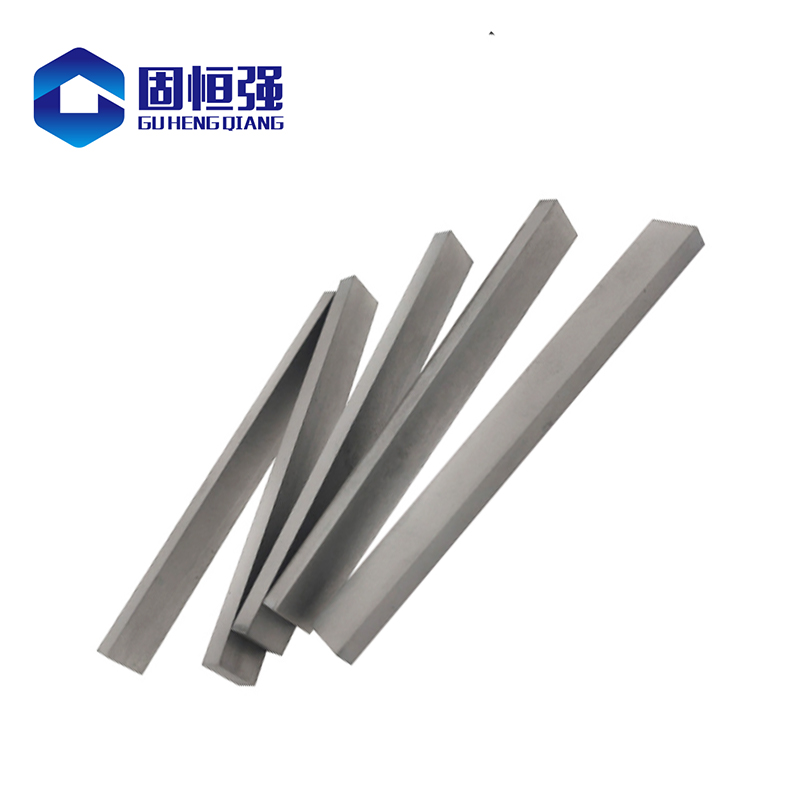

Product Showcase