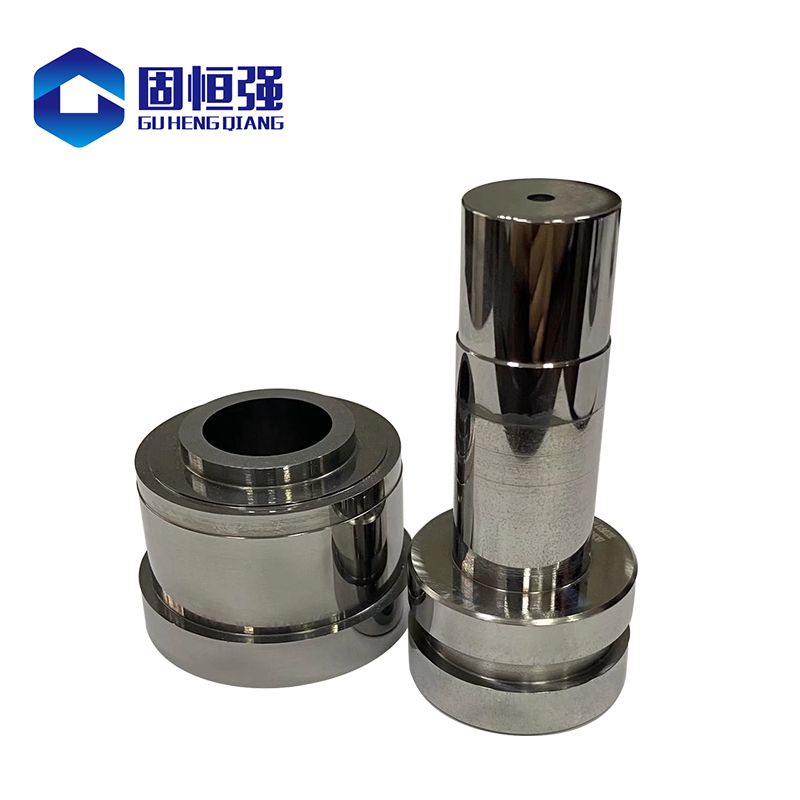

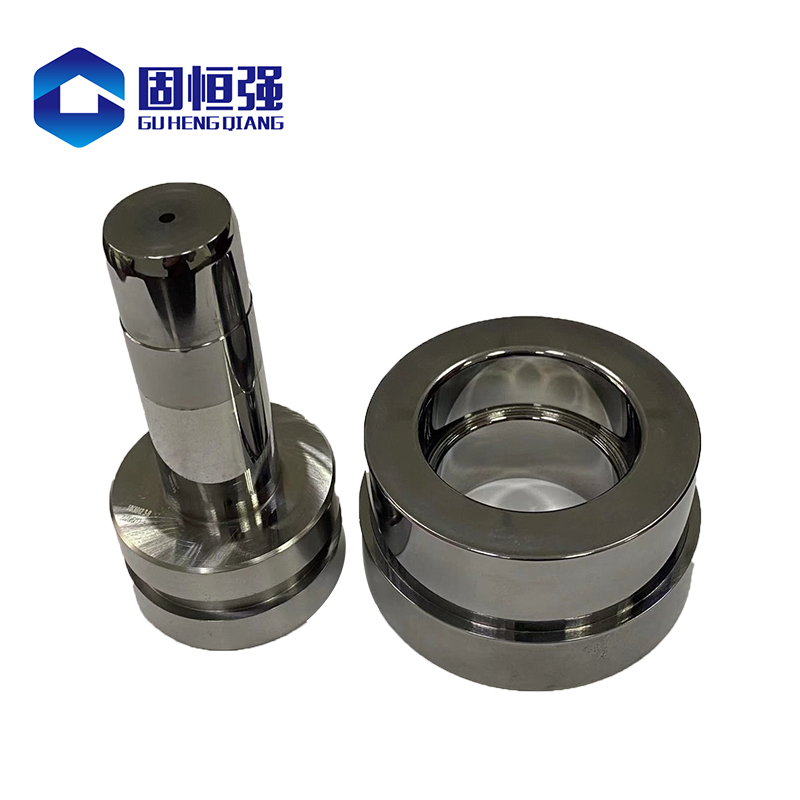

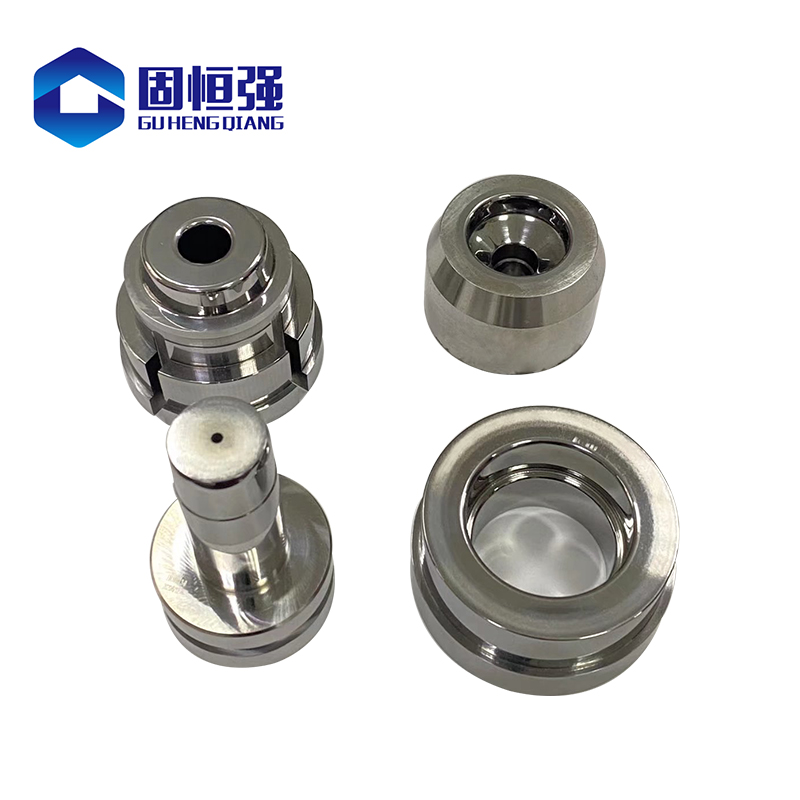

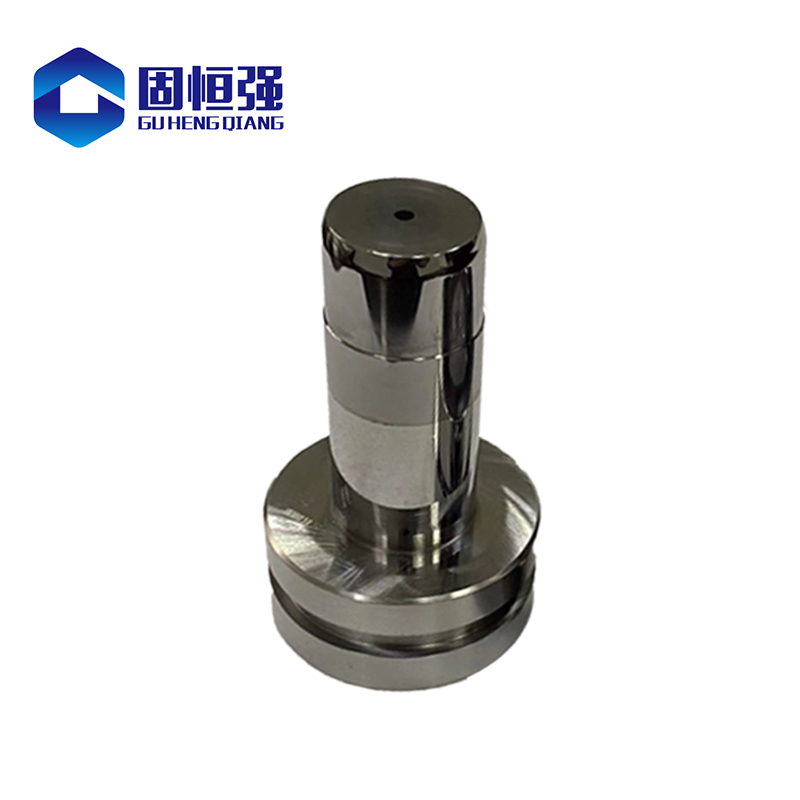

Carbide Non-standard Parts Cemented Carbide Tensile Bar Membrane Shell

Carbide Non-standard Parts Introduction

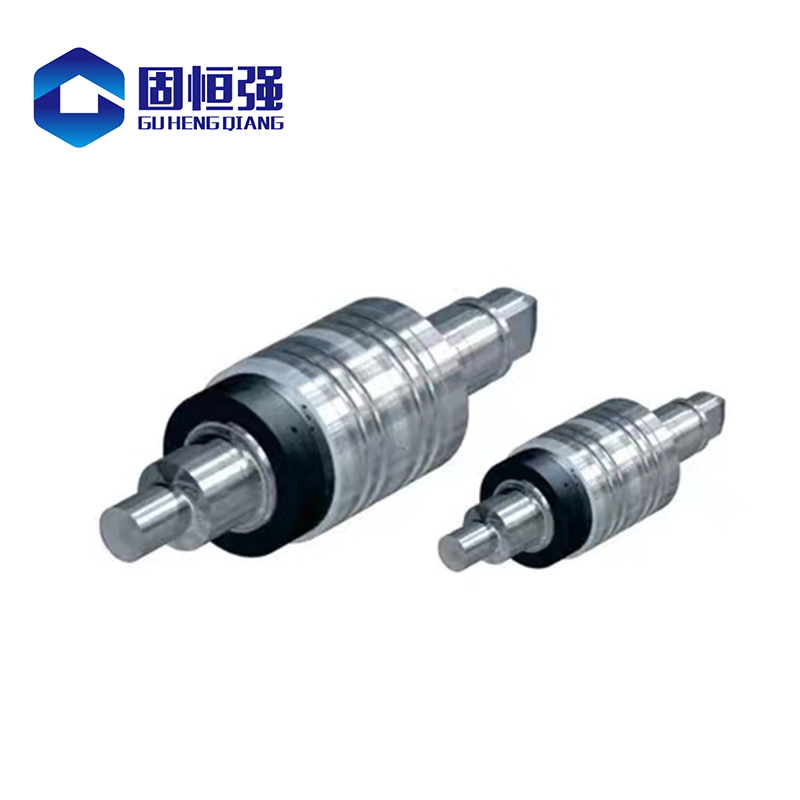

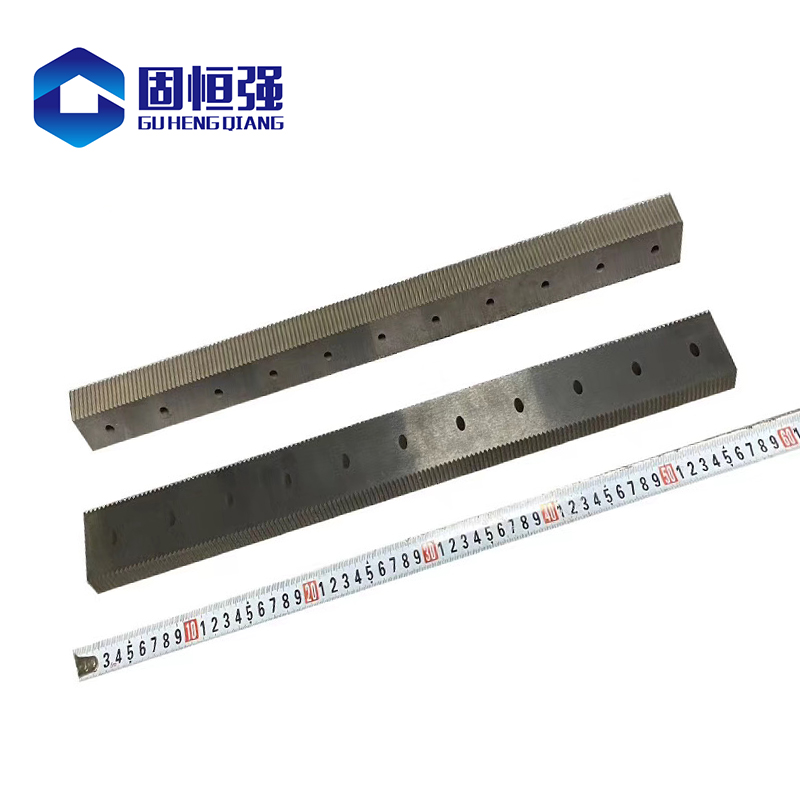

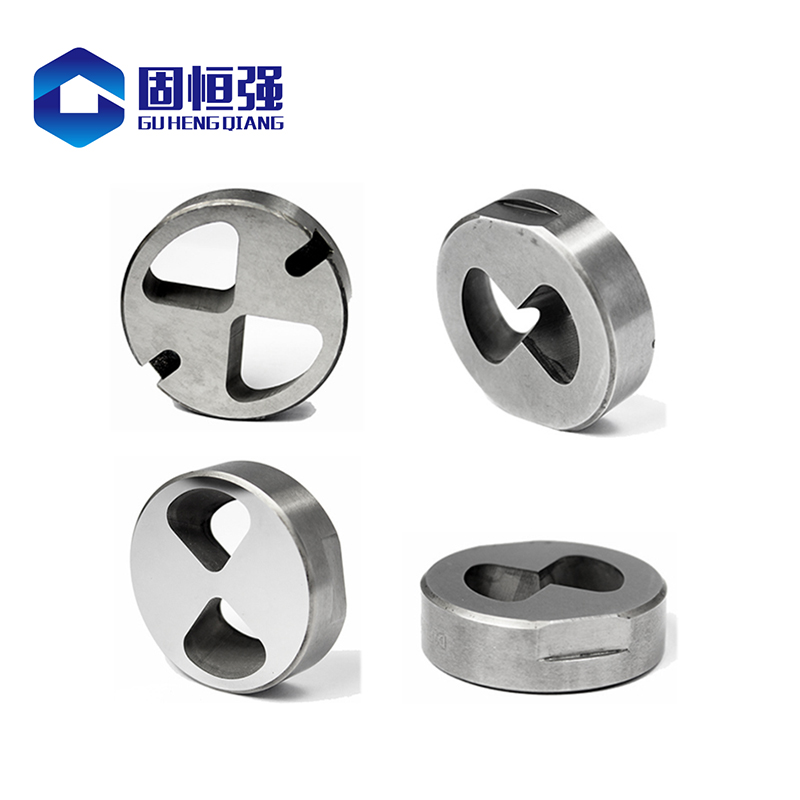

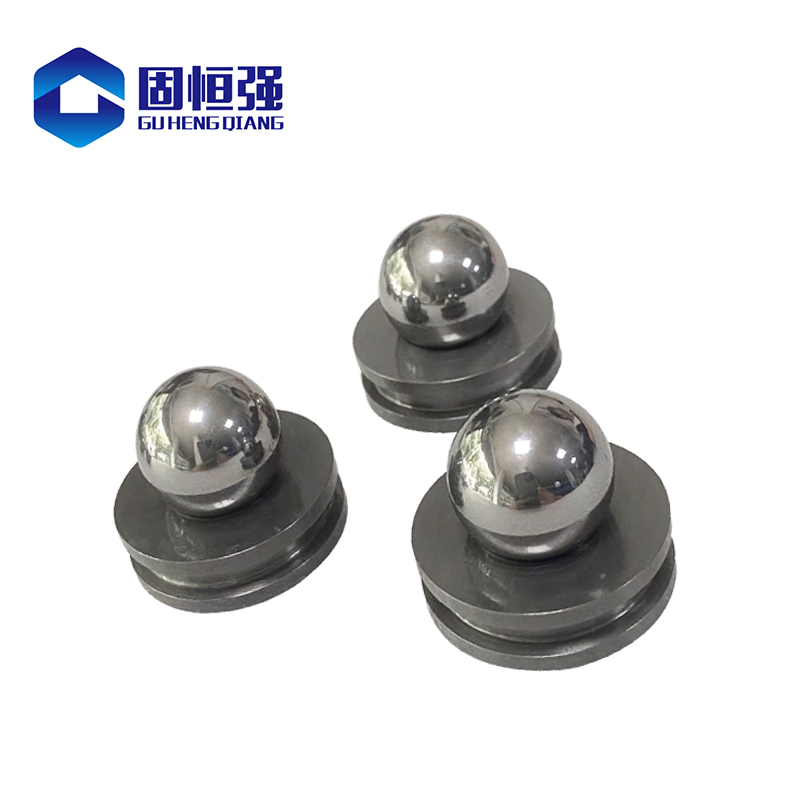

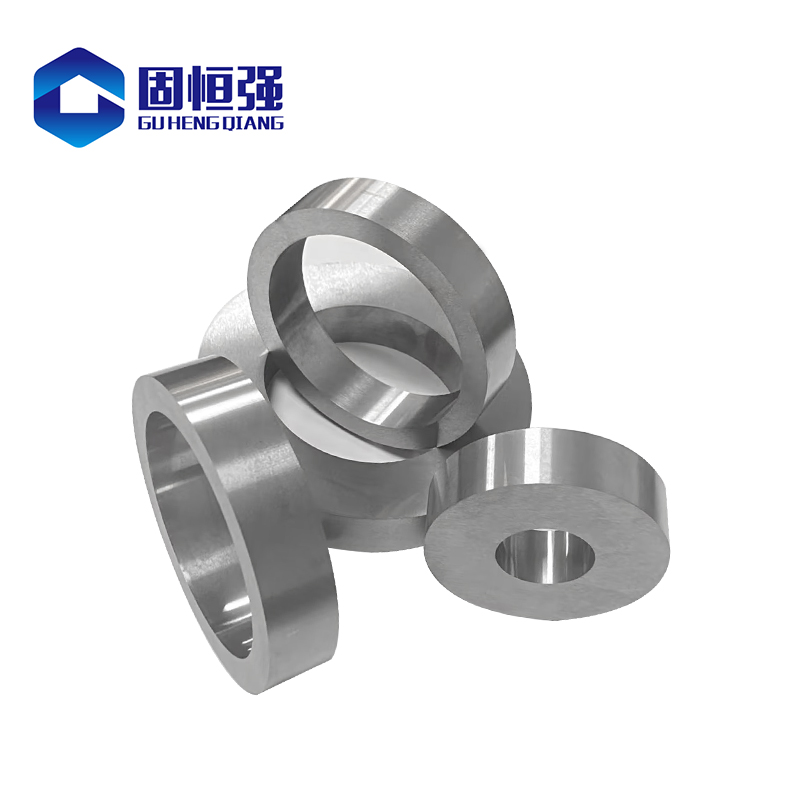

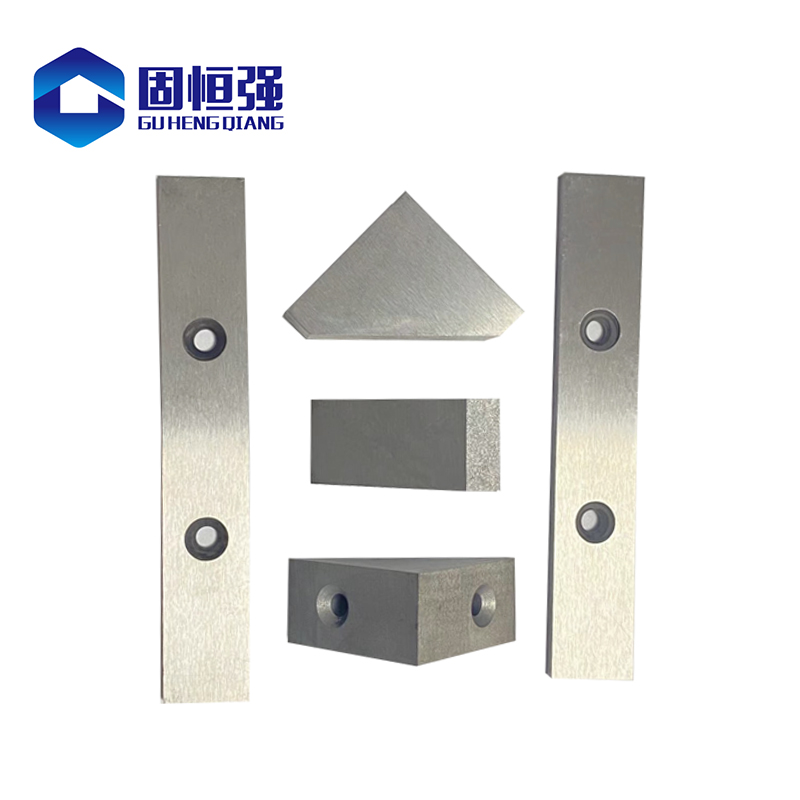

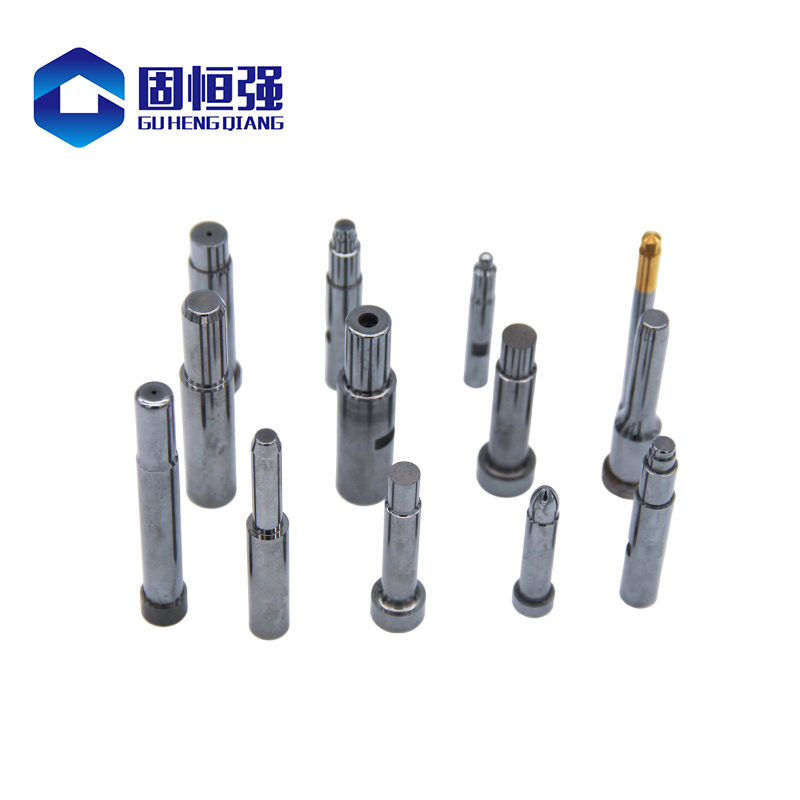

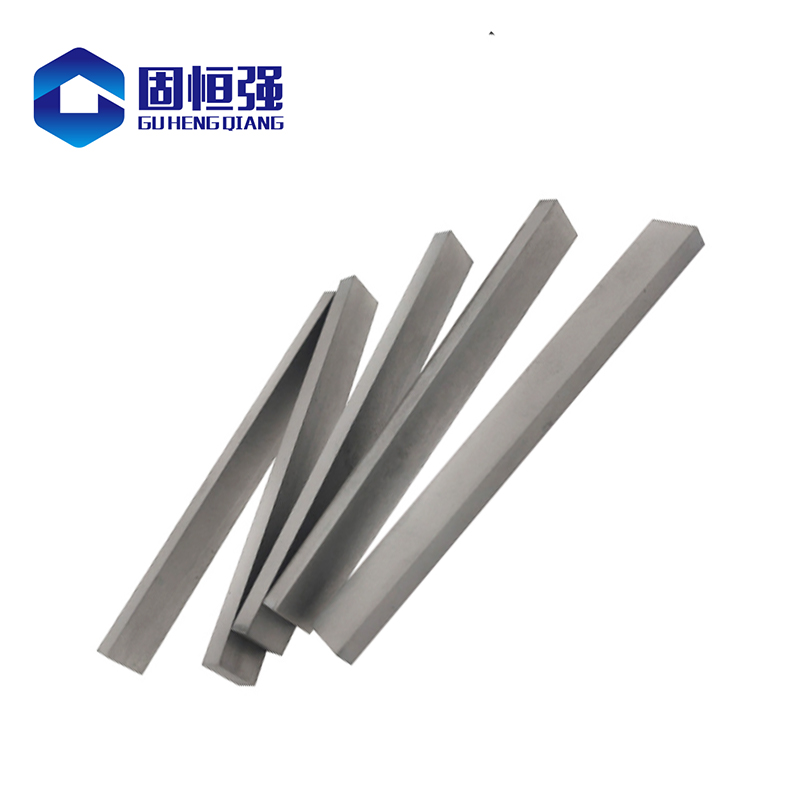

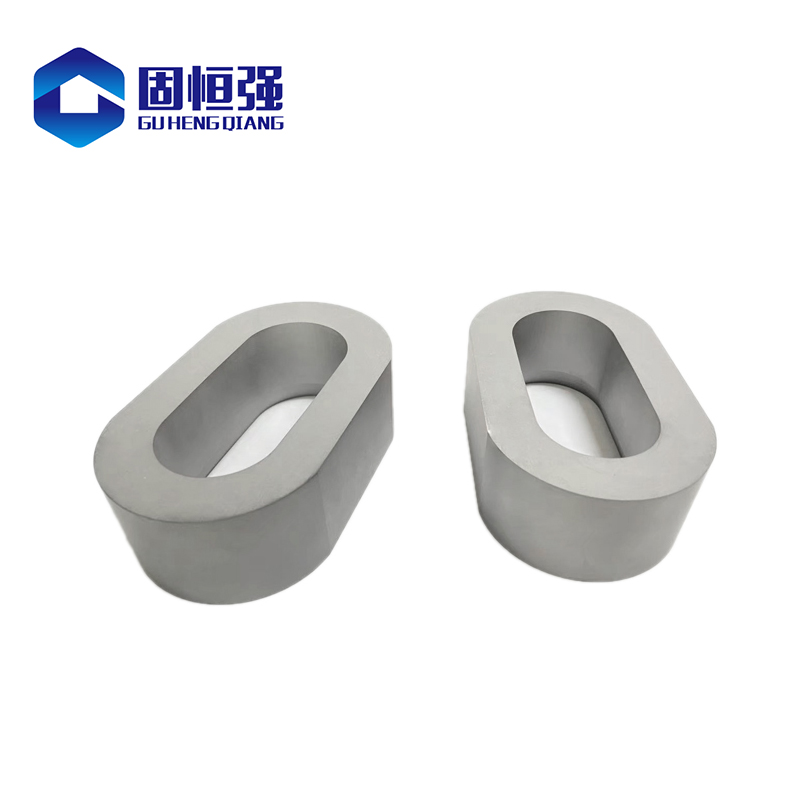

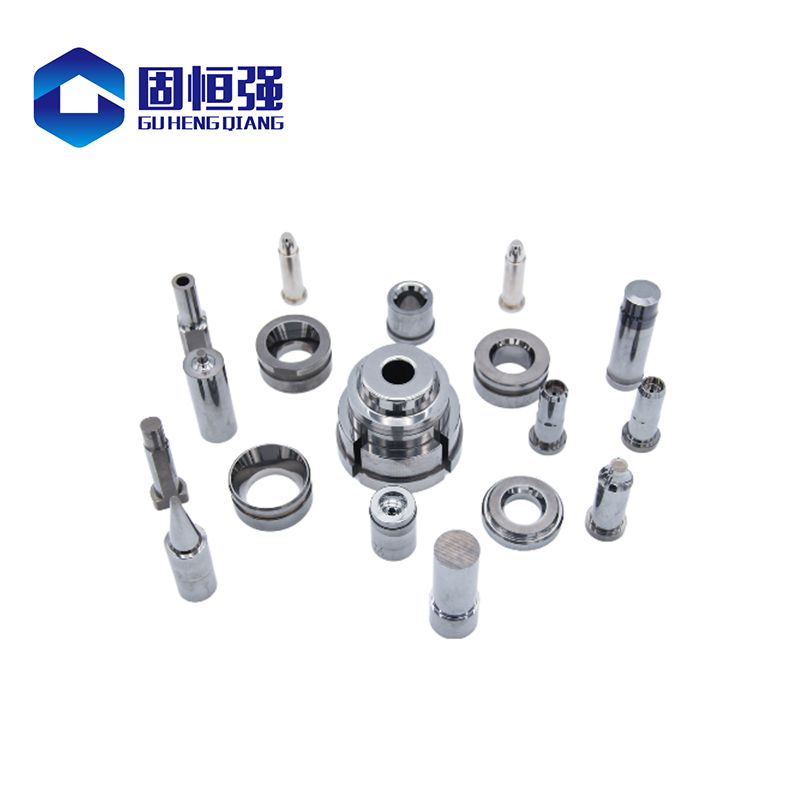

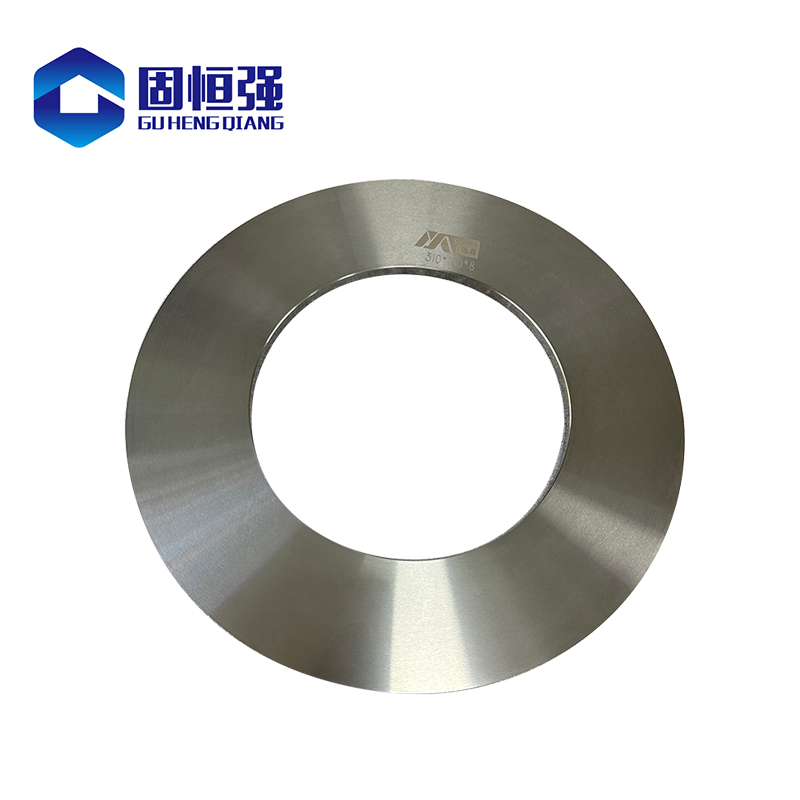

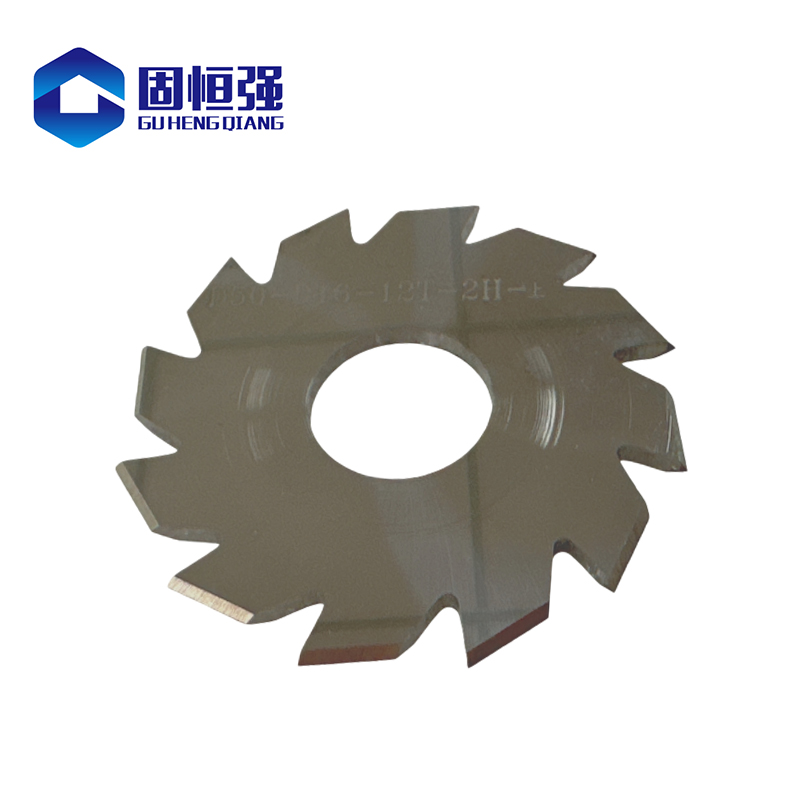

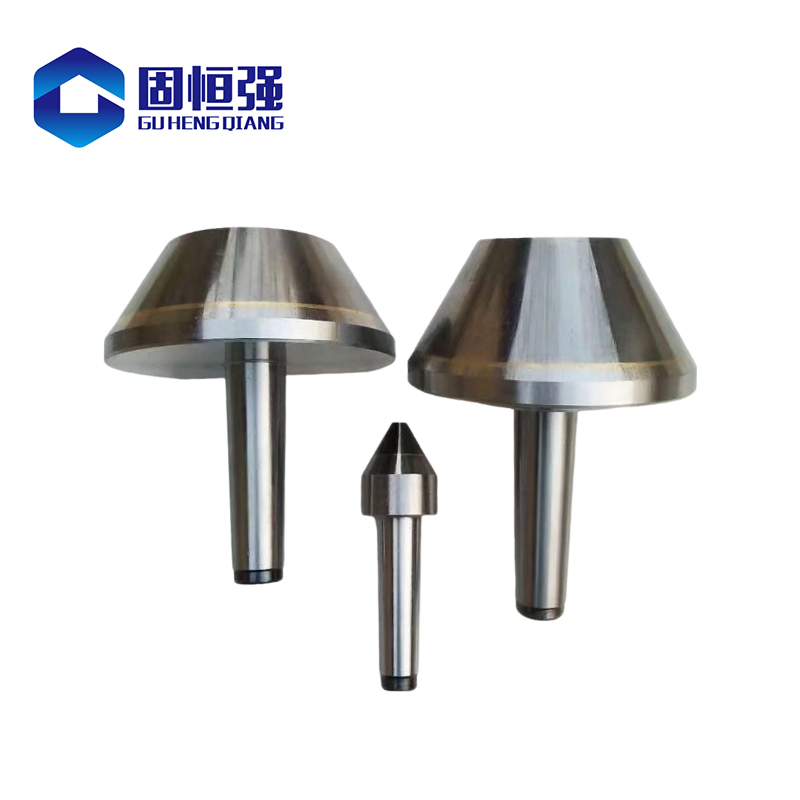

Cemented carbide shaped products are mainly composed of various shapes, a mould combination products and tool shaped combination products.

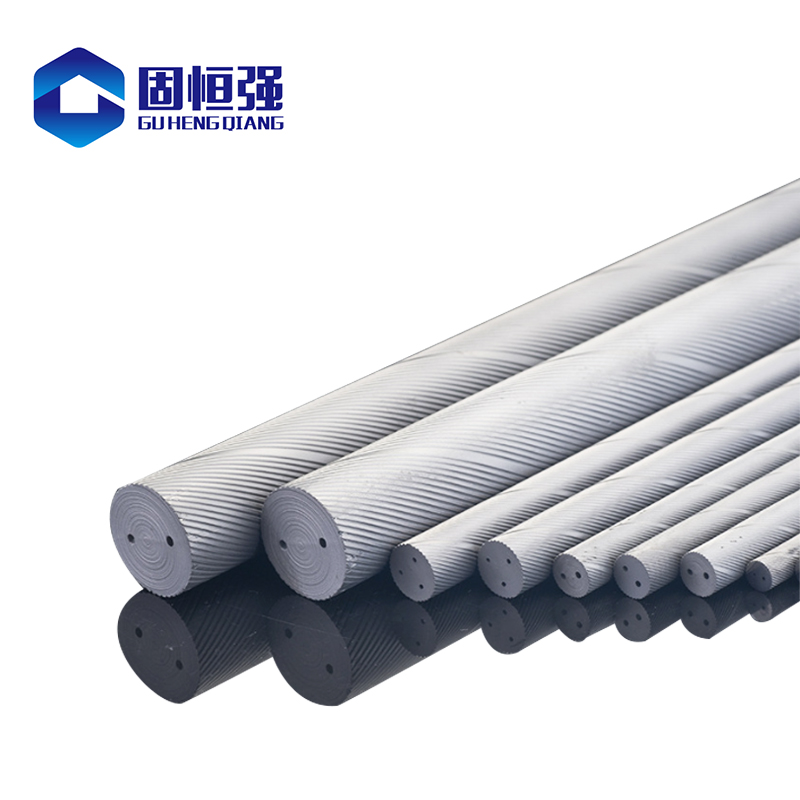

Processing technology: blank prefabricated semi-finished products, through the discharge, slow wire, turning, milling, grinding, PG and other processes. It has the advantages of high hardness, high finish, good toughness, good abrasion resistance and long service life.

Application Areas of Cemented Carbide Non-standard Parts

1.Widely used in drawing, drawing, stamping, cold piering, shaping moulds, forming moulds and other mould industries;

2.Applied in the production of stainless steel tableware, utensils, hardware fittings, carbide valve plates, valve seats, valves and so on;

3.Magnetic industry and non-magnetic moulds

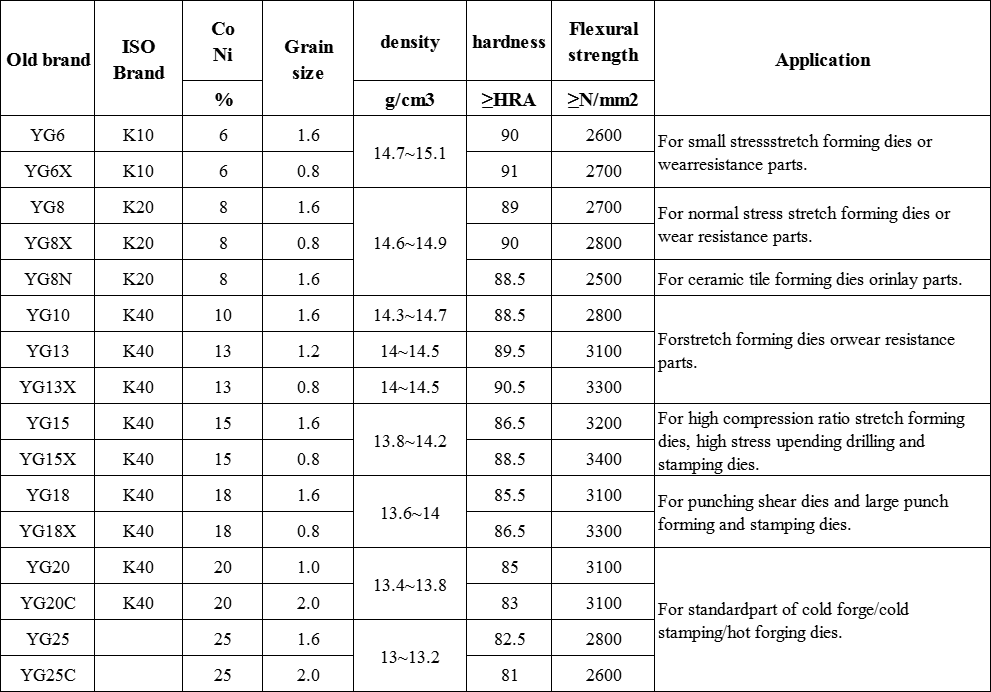

Cemented Carbide Non-standard Parts Grade

Advantages of Cemented Carbide Non-Standard Parts

1.Adopting high-quality cemented carbide raw materials, using cold pressing, vacuum sintering process and other advanced moulding technologies, we produce various complicated shapes of cemented carbide non-standard shaped products with stable performance and reliable quality;

2.Unique production control and testing technology, the internal stress of the production of shaped products has been controlled, effectively avoiding the cracking phenomenon of the product in the wire cutting, away from defects such as porosity and cracks;

3.Non-destructive ultrasonic flaw detection, no sand holes, no air holes, high material density; high strength, impact resistance, high wear resistance, long service life.

Cemented Carbide Non-standard Parts Customised Instructions

1.Size and specification: process and produce according to the samples or drawings provided by customers;

2.Recommended grades and design solutions according to customers’ working conditions, solving customers’practical needs with professionalism.

FAQ

Q1. Are you a manufacturer?

A: Yes, we are. We have the best factory to produce for you,could guarantee the price is the most competitive.

Q2. What is your terms of payment?

A: T/T 50% as deposit, and 50% balance before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. How about your delivery time?

A: Lead time as fast as 7-15 days!

Q4. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.Our production is based on ISO9001,we have more than 10 years experience of QC team and strictly quality control system in our production process.

Q6. What about the package?

A.It can make as the you need and depend on the products shapes. Generally, we can provide iron drum, carton, wooden case, and bag packages.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Our company produces cemented carbide products, a variety of specifications, welcome to order! For you to comprehensively solve the production problems!